Grinding force model for rotary ultrasonic grinding of TiBw mesh reinforced titanium matrix composites

-

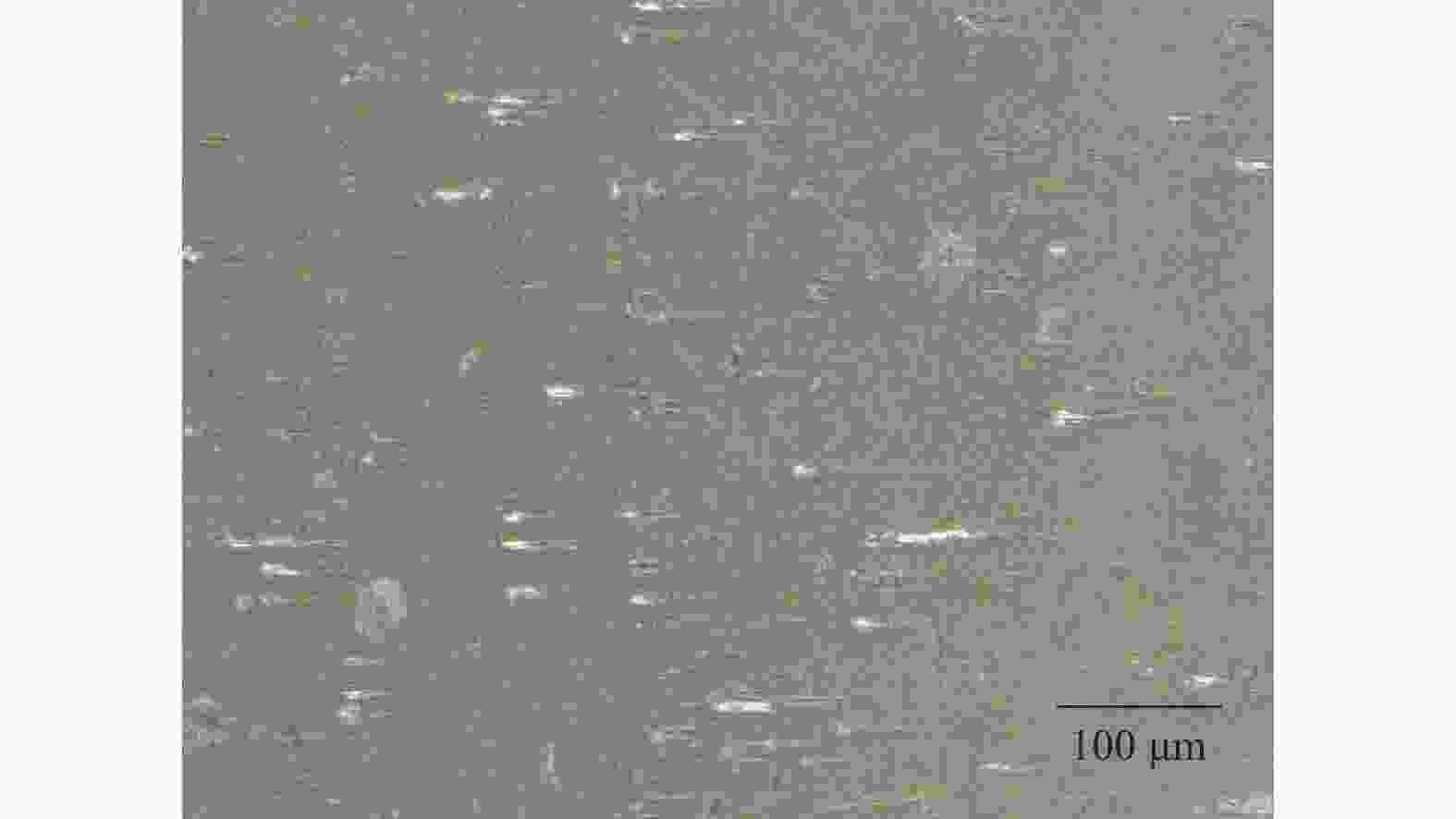

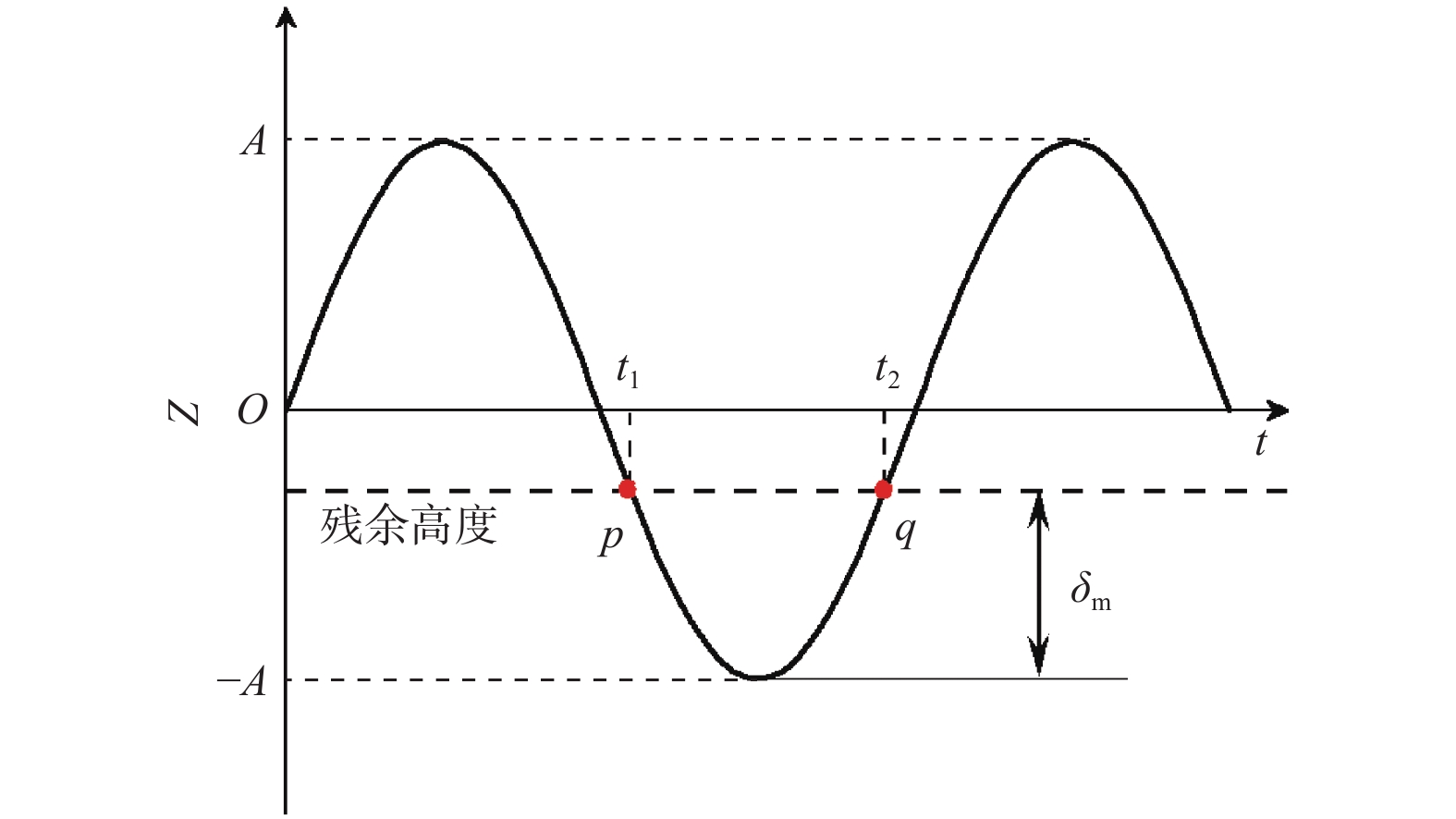

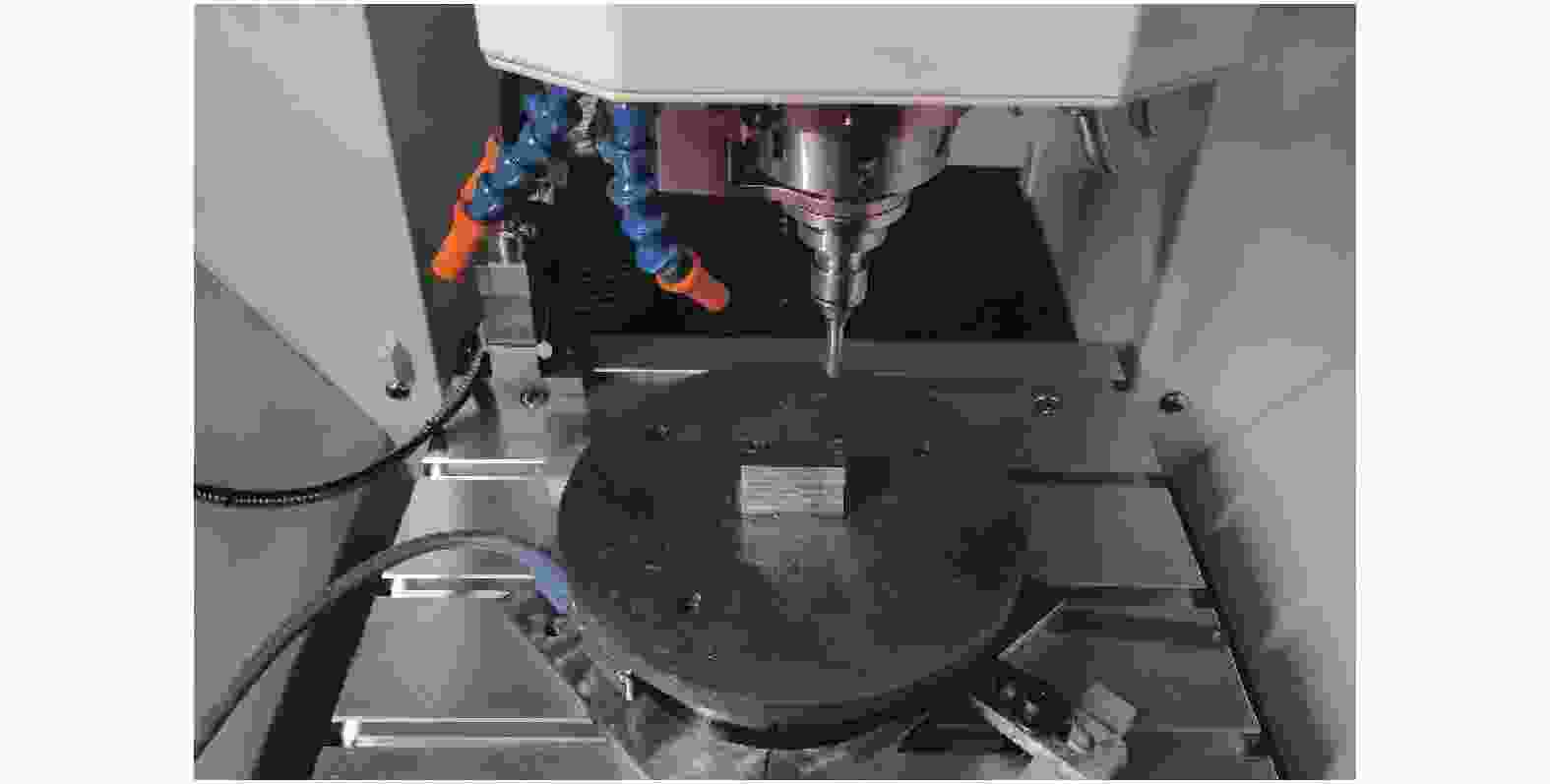

摘要: 针对TiBw网状增强钛基复合材料加工时表面质量差、加工过程不平稳等问题,开展其旋转超声磨削的法向磨削力研究。分析旋转超声磨削中的磨粒运动规律,建立旋转超声磨削TiBw网状增强钛基复合材料的法向磨削力模型,并通过单因素磨削试验对模型进行验证。结果表明:在一定的主轴转速、进给速度、磨削深度及固定磨削宽度条件下,法向磨削力随主轴转速的增加而减小,随进给速度、磨削深度的增加而增大,且其磨削试验值与模型计算值的相对误差绝对值均在6%以内。模型很好地预测了TiBw网状增强钛基复合材料磨削时的法向磨削力,验证了预测模型的有效性。

-

关键词:

- TiBw网状增强钛基复合材料 /

- 旋转超声磨削 /

- 磨削力模型

Abstract: To solve the problems of poor surface quality and unevenness during the processing of TiBw mesh reinforced titanium matrix composites, the normal grinding forces of rotary ultrasonic grinding were studied. The motion law of abrasive particles in rotary ultrasonic grinding was analyzed, the normal grinding force model of rotary ultrasonic grinding TiBw mesh reinforced titanium matrix composites was established, and the model was verified by single factor grinding experiment. The results show that under certain spindle speed, feed speed, grinding depth, fixed grinding width, ultrasonic amplitude and ultrasonic vibration frequency, the normal grinding forces decrease with the increase of spindle speeds and increase with the increase of feed speeds and grinding depths, and the absolute values of relative error between the grinding experimental values and the model calculated values are within 6%. The model well predicts the normal grinding force during grinding of TiBw mesh reinforced titanium matrix composites, which verifies the effectiveness of the prediction model. -

表 1 正交试验参数

Table 1. Orthogonal experimental parameters

水平 因素 主轴转速

n / (r·min−1)进给速度

vf / (mm·min−1)磨削深度

ap / μm磨削宽度

b / mm1 6 000 10 8 6 2 8 000 15 12 3 10 000 20 16 4 12 000 25 20 表 2 单因素试验参数

Table 2. Single factor experiment parameters

因素 取值 主轴转速 n / (r·min−1) 6 000,7 000,8 000,9 000,

10 000,11 000,12 000进给速度 vf / (mm·min−1) 8,10,12,14,16,18,20 磨削深度 ap / μm 8,10,12,14,16,18,20 磨削宽度 b / mm 6 超声振幅 A / μm 2 超声频率 f / Hz 30 000 -

[1] 刘世锋, 宋玺, 薛彤, 等. 钛合金及钛基复合材料在航空航天的应用和发展 [J]. 航空材料学报,2020,40(3):77-94.LIU Shifeng, SONG Xi, XUE Tong, et al. Application and development of titanium alloy and titanium matrix composites in aerospace field [J]. Journal of Aeronautial Materials,2020,40(3):77-94. [2] BLAU P, JOLLY B. Relationships between abrasive wear, hardness, and grinding characteristics of titanium-based metal-matrix composites [J]. Journal of Materials Engineering and Performance,2009,18:424-432. doi: 10.1007/s11665-008-9227-3 [3] ZHAO B, DING W, DAI J, et al. A comparison between conventional speed grinding and super-high speed grinding of (TiCp+TiBw)/Ti-6Al-4V composites using vitrified CBN wheel [J]. The International Journal of Advanced Manufacturing Technology,2014,72(1/2/3/4):69-75. doi: 10.1007/s00170-014-5656-3 [4] BEJJANI R, SHI B, ATTIA H, et al. Laser assisted turning of titanium metal matrix composite [J]. CIRP Annals,2011,60(1):61-64. doi: 10.1016/j.cirp.2011.03.086 [5] LI Z, DING W, LIU C, et al. Grinding performance and surface integrity of particulate-reinforced titanium matrix composites in creep-feed grinding [J]. The International Journal of Advanced Manufacturing Technology,2018,94(9):3917-3928. [6] 胡智特, 秦娜, 刘凡. 超声振动车削TC4钛合金的切削性能研究 [J]. 机械设计与制造,2018(2):164-166.HU Zhite, QIN Na, LIU Fan. Study on cutting performance of TC4 titanium alloy by ultrasonic vibration turning [J]. Machinery Design & Manufacture,2018(2):164-166. [7] 马超, 张建华, 陶国灿. 超声振动辅助铣削加工钛合金表面摩擦磨损性能研究 [J]. 表面技术,2017,46(8):115-119.MA Chao, ZHANG Jianhua, TAO Guocan. Wear and friction properties of titanium alloy surface subject to ultrasonic vibration assisted milling [J]. Surface Technology,2017,46(8):115-119. [8] 张习芳, 郑侃, 廖文和, 等. 超声振动辅助铣削钛合金的表面完整性研究 [J]. 工具技术,2017,51(9):12-16.ZHANG Xifang, ZHENG Kan, LIAO Wenhe, et al. Investigation on surface integrity for ultrasonic vibration assisted milling titanium alloy [J]. Tool Engineering,2017,51(9):12-16. [9] 杨宇辉, 陈海彬, 马文举, 等. 氧化锆陶瓷旋转超声加工脆塑转变特性研究 [J]. 表面技术,2020,49(4):90-97.YANG Yuhui, CHEN Haibin, MA Wenju, et al. Study of the characteristics of brittle-ductile transition in rotary ultrasonic machining of zirconia ceramics [J]. Surface Technology,2020,49(4):90-97. [10] TESFAY H, XU Z, LI Z. Ultrasonic vibration assisted grinding of bio-ceramic materials: An experimental study on edge chippings with Hertzian indentation tests [J]. The International Journal of Advanced Manufacturing Technology,2016,86(9):3483-3494. [11] SINGH R, SINGHAL S. Rotary ultrasonic machining of macor ceramic: An experimental investigation and microstructure analysis [J]. Materials and Manufacturing Processes,2016,32(9):927-939. [12] WANG H, PEI Z, CONG W. A mechanistic cutting force model based on ductile and brittle fracture material removal modes for edge surface grinding of CFRP composites using rotary ultrasonic machining [J]. International Journal of Mechanical Sciences,2020,176:105551. doi: 10.1016/j.ijmecsci.2020.105551 [13] ZHOU M, ZHENG W. A model for grinding forces prediction in ultrasonic vibration assisted grinding of SiCp/Al composites [J]. The International Journal of Advanced Manufacturing Technology,2016,87(9/10/11/12):3211-3224. doi: 10.1007/s00170-016-8726-x -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS