Analysis on wear characteristics of diamond tools based on cutting technology

-

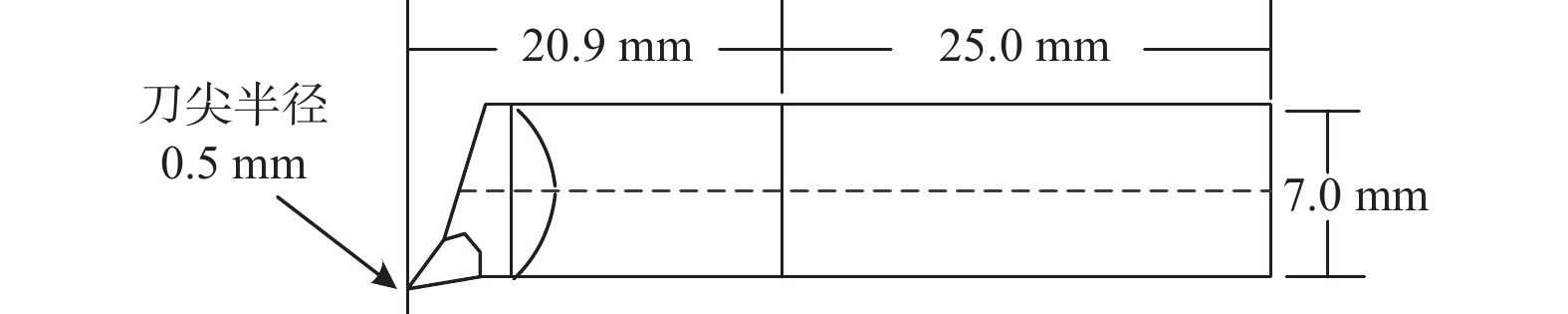

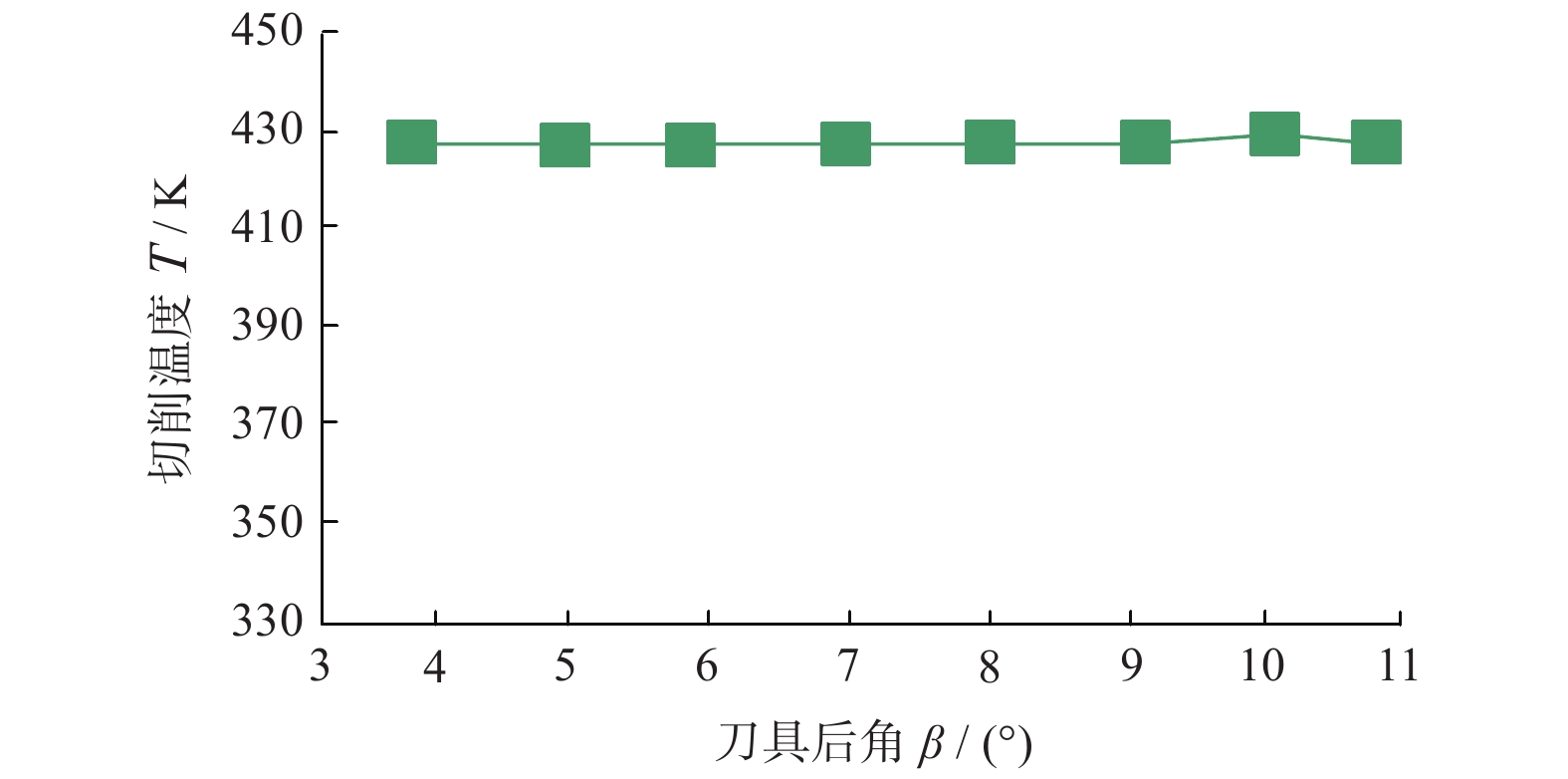

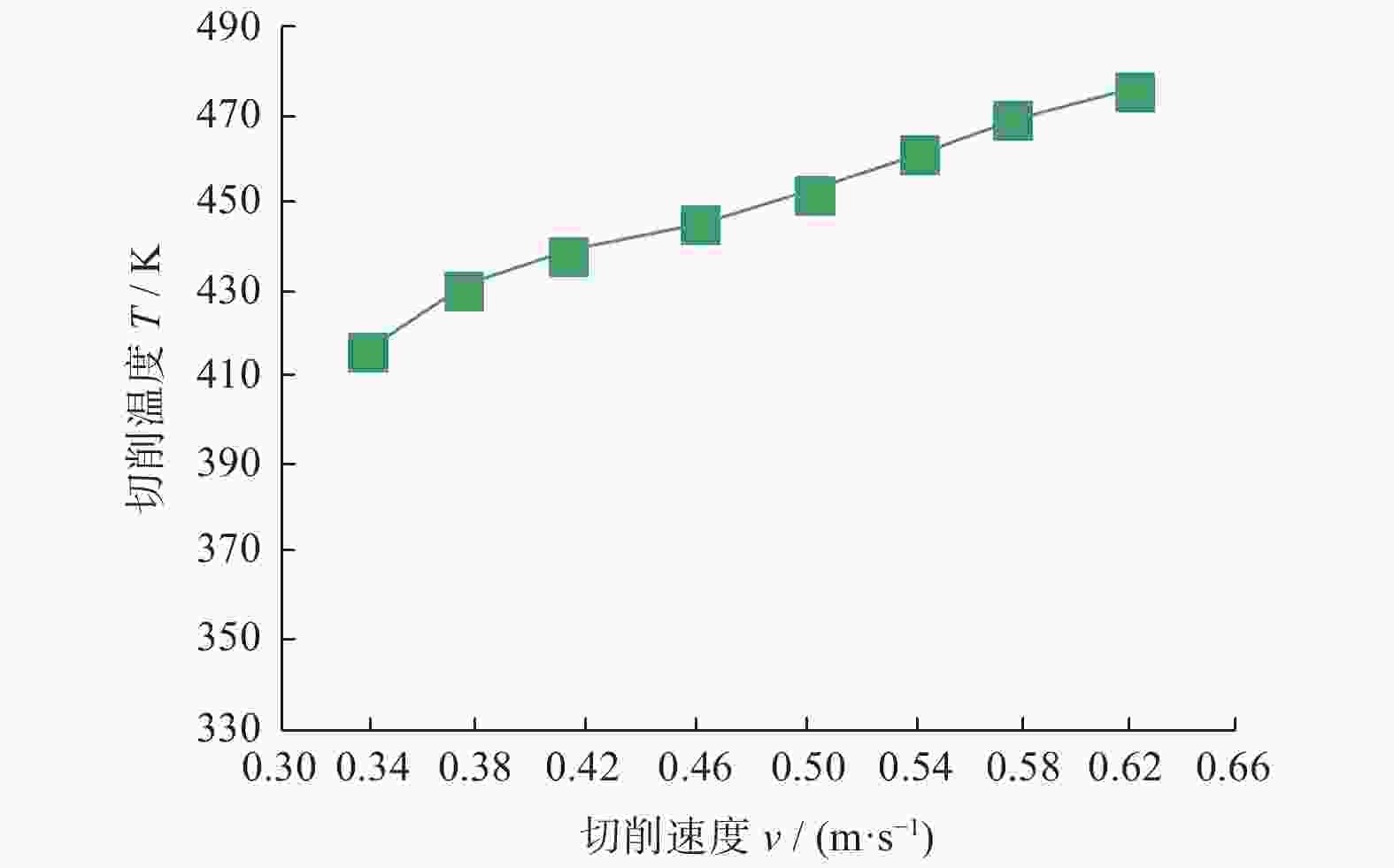

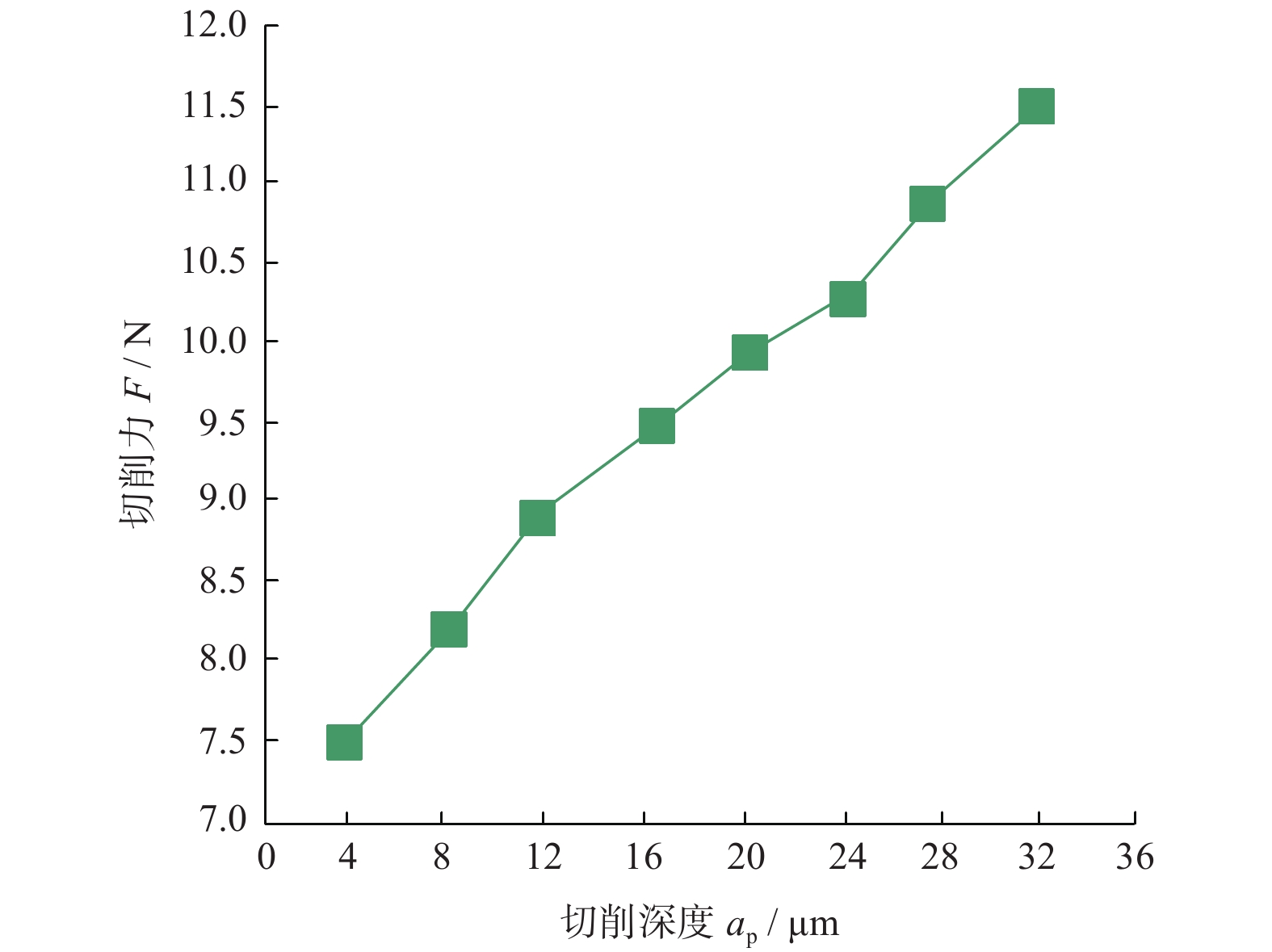

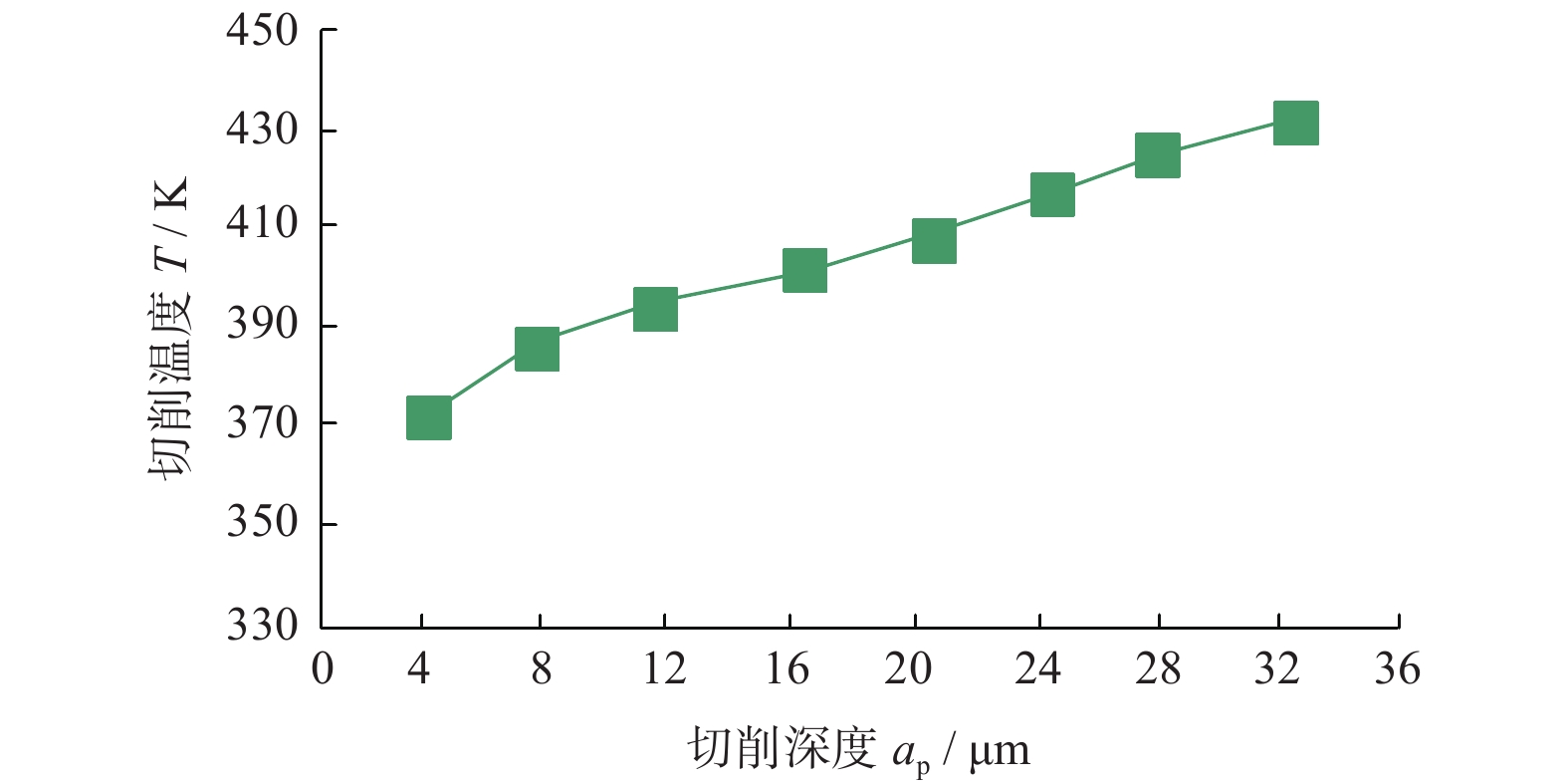

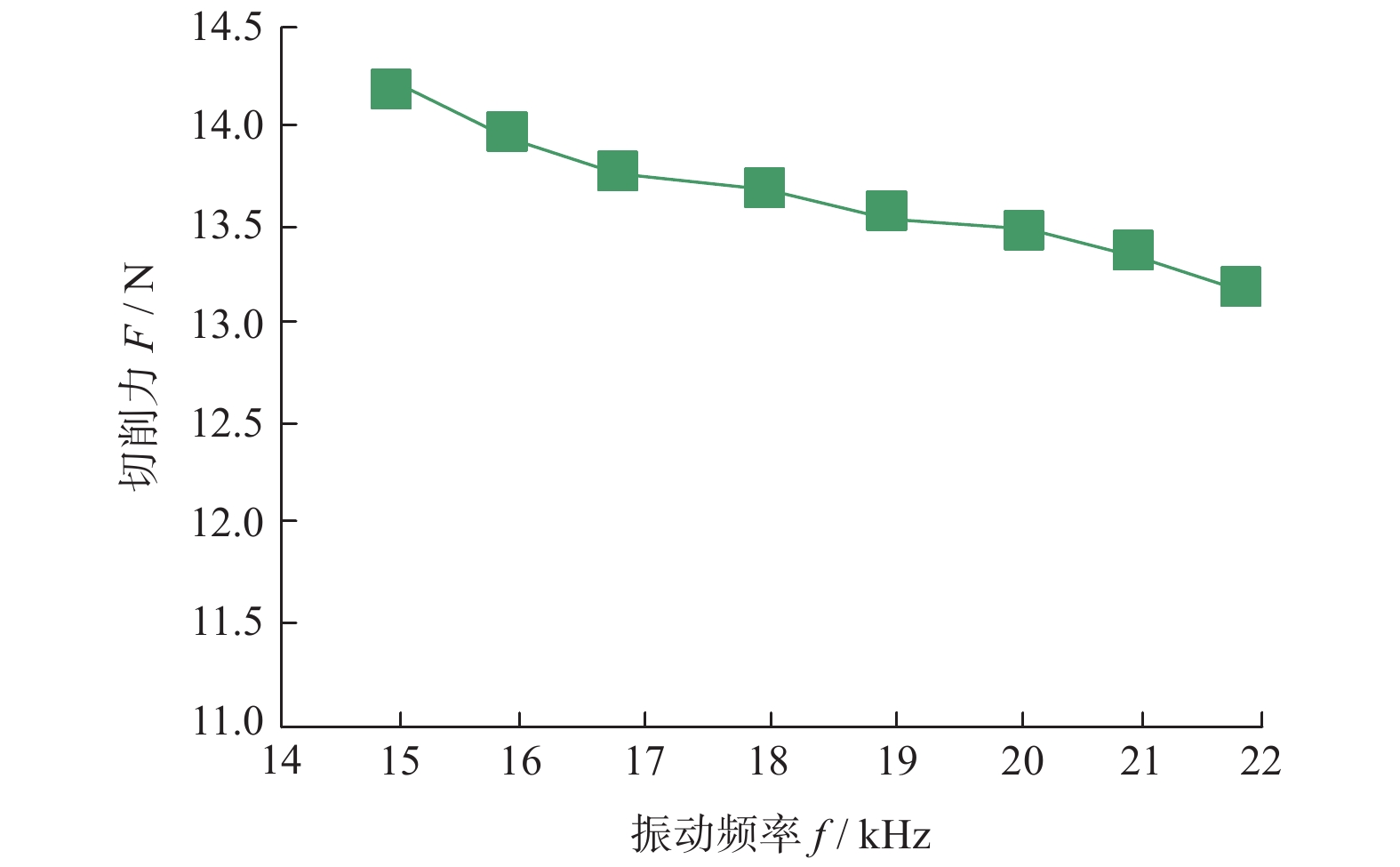

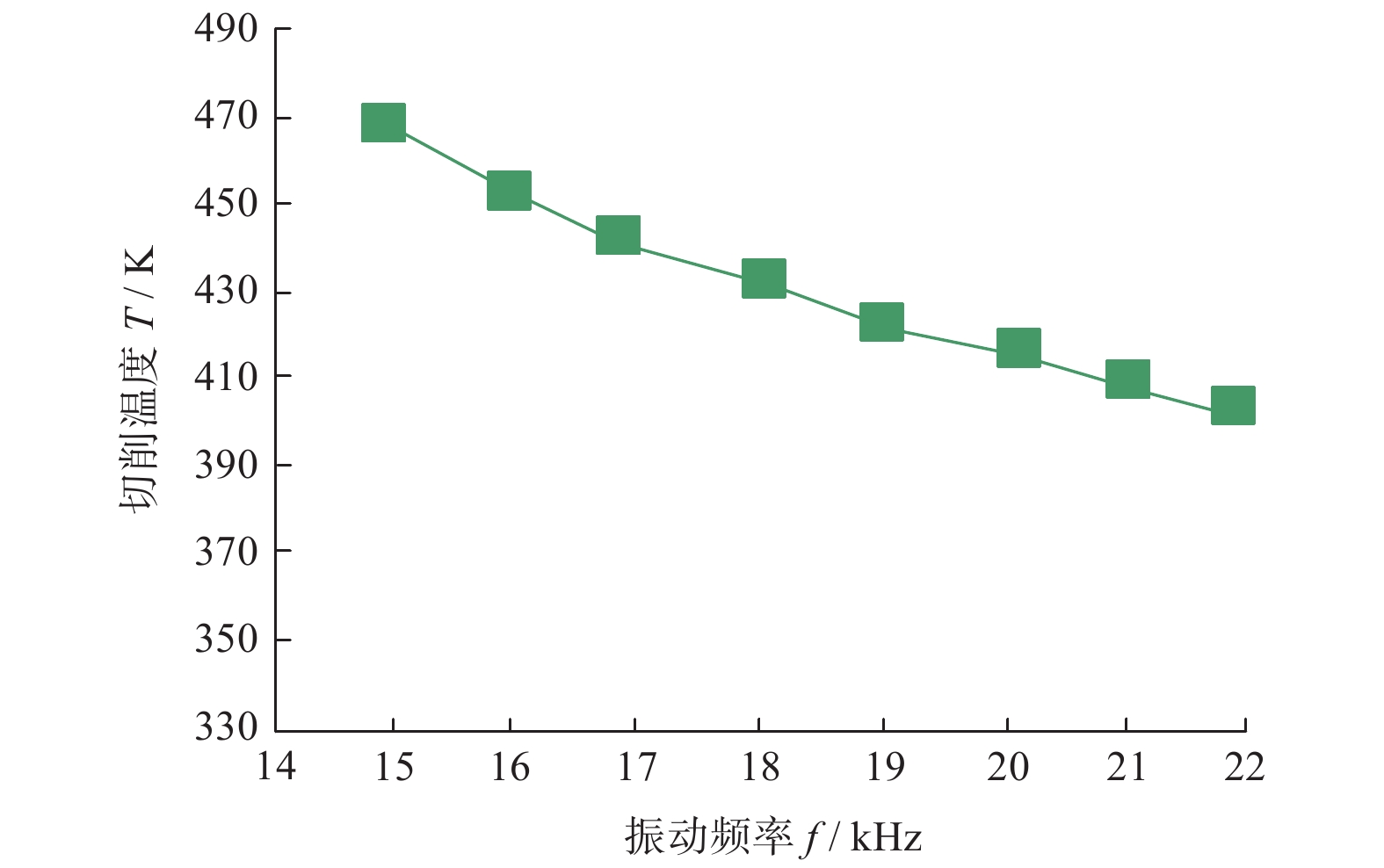

摘要: 金刚石刀具的磨损情况决定其使用寿命。用金刚石PCD刀具切削6061-T6镁铝合金工件,通过不同切削速度、切削深度、振动频率、刀具后角时的切削力及切削温度变化,研究不同刀具前后角、进给量、切削转速时的工件表面粗糙度及刀具磨损面积。结果表明:金刚石刀具的切削力和切削温度随切削速度、切削深度的增加而增大,随振动频率的增加而减小;刀具后角增大,金刚石刀具的切削力呈先下降而后缓缓上升趋势,但对切削温度的影响很小。当刀具前角为10°,刀具后角为8°,切削速度为0.46 m/s,切削深度为28 μm,进给量为0.10 mm/r,切削转速为4100 r/min,振动频率为22 kHz,切削振幅为9 μm时,金刚石刀具的磨损面积最小,磨损程度最低,使用寿命最长,但工件的表面粗糙度稍高。Abstract: The wear condition of diamond tools determines its service life. The 6061-T6 magnesium-aluminum alloy workpiece was cutted with diamond PCD tool. Through the changes of cutting forces and cutting temperatures at different cutting speeds, cutting depths, vibration frequencies and tool back angles, the workpiece surface roughnesses and tool wear areas at different tool back and forth angles, feed values and speeds of revolution were studied. The results show that the cutting forces and the cutting temperatures increase with the increase of cutting speeds and cutting depths, and decrease with the increase of vibration frequencies. With the increase of the tool back angles, the cutting forces of diamond tool decrease first and then increase slowly, but it has little effect on the cutting temperatures. When the rake angle of the tool is 10°, the back angle of the tool is 8°, the cutting speed is 0.46 m/s, the cutting depth is 28 μm, the feed value is 0.10 mm/r, the speed of revolution is 4 100 r/min, the vibration frequency is 22 kHz and the cutting amplitude is 9 μm, the diamond tool has the smallest wear area, the lowest degree of wear and the longest service life, but the surface roughness of the workpiece is slightly higher.

-

Key words:

- diamond cutting tool /

- cutting technology /

- wear characteristics /

- cutting force

-

表 1 金刚石刀具与工件的物理参数

Table 1. Physical parameters of diamond tool and workpiece

物理参数 镁铝合金工件 金刚石刀具 材料密度 ρ / (kg·m−3) 7 780 3 410 泊松比 ε 0.3 0.1 弹性模量 E / GPa 207 1 045 比热 c / [J·(kg·℃)−1] 501 415 热导率 λ / [W·(m·K)−1] 43.4 980.0 热膨胀系数 α / K−1 1.29×10−5 1.25×10−6 表 2 影响刀具切削的参数

Table 2. Parameters affecting tool cutting

参数 取值 刀具前角 α / (°) 3,4,5,6,7,8,9,10 刀具后角 β / (°) 4,5,6,7,8,9,10,11 切削速度 v / (m·s−1) 0.34,0.38,0.42,0.46,0.50,0.54,0.58,0.62 切削深度 ap / μm 4,8,12,16,20,24,28,32 进给量 vf / (mm·r−1) 0.03,0.04,0.05,0.06,0.07,0.08,0.09,0.10 切削转速 n / (r·min−1) 2 000,2 300,2 600,2 900,3 200,3 500,3 800,4 100 超声频率 f / kHz 15,16,17,18,19,20,21,22 超声振幅 A / μm 9 表 3 工件表面粗糙度及刀具表面磨损面积变化

Table 3. Workpiece surface roughness and tool surface wear area changes

刀具前角

α / (°)表面粗糙度

Ra / nm磨损面积

S / mm2转速

n / (r·min−1)表面粗糙度

Ra / nm磨损面积

S / mm2进给量

vf / (mm·r−1)表面粗糙度

Ra / nm磨损面积

S / mm23 21.34 0.76 × 10−3 2 000 25.61 0.85 × 10−3 0.03 21.24 0.73 × 10−3 4 21.73 0.77 × 10−3 2 300 23.26 0.79 × 10−3 0.04 23.64 0.71 × 10−3 5 22.61 0.79 × 10−3 2 600 22.43 0.77 × 10−3 0.05 24.85 0.69 × 10−3 6 22.81 0.81 × 10−3 2 900 21.86 0.74 × 10−3 0.06 26.24 0.68 × 10−3 7 23.64 0.82 × 10−3 3 200 24.62 0.71 × 10−3 0.07 27.84 0.67 × 10−3 8 26.49 0.76 × 10−3 3 500 26.43 0.68 × 10−3 0.08 27.86 0.65 × 10−3 9 28.61 0.64 × 10−3 3 800 28.68 0.64 × 10−3 0.09 27.88 0.64 × 10−3 10 29.58 0.52 × 10−3 4 100 29.63 0.62 × 10−3 0.10 27.91 0.62 × 10−3 -

[1] 闫广宇, 吴玉厚, 赵德宏, 等. CVD金刚石涂层刀具高效铣削天然理石的切削特性试验研究 [J]. 润滑与密封,2018,43(7):52-57,62.YAN Guangyu, WU Yuhou, ZHAO Dehong, et al. Experimental study on cutting characteristics of CVD diamond coated tool in high-efficiency machining of natural marble [J]. Lubrication Engineering,2018,43(7):52-57,62. [2] 黄帅, 徐文骥, 刘新. 冷等离子体辅助金刚石切削黑色金属基础研究 [J]. 机械工程学报,2019,55(6):155.HUANG Shuai, XU Wenji, LIU Xin. Basic research on cold plasma assisted diamond cutting of ferrous metals [J]. Journal of Mechanical Engineering,2019,55(6):155. [3] 陈俊云, 李召阳, 王海东. 飞秒激光烧蚀纳米孪昌金刚石的研究 [J]. 制造技术与机床,2019,681(3):87-91.CHEN Junyun, LI Zhaoyang, WANG Haidong. Femtosecond laser ablation of nano twinned diamond [J]. Manufacturing Technology & Machine Tool,2019,681(3):87-91. [4] 赵民, 徐博文, 贾乾忠. 金刚石圆柱铣刀铣削花岗岩的铣削力研究 [J]. 机械设计与制造,2019,335(1):13-15.ZHAO Min, XU Bowen, JIA Qianzhong. Study on milling force of diamond cylindrical cutter milling granite [J]. Machinery Design & Manufacture,2019,335(1):13-15. [5] 张而耕, 牛帅, 陈强, 等. 含氢和无氢类金刚石涂层的制备及切削性能研究 [J]. 陶瓷学报,2019,40(5):637-643.ZHANG Ergeng, NIU Shuai, CHEN Qiang, et al. Preparation and cutting performance of hydrogen-containing and hydrogen-free diamond-like coating [J]. Journal of Ceramics,2019,40(5):637-643. [6] 许宁萍, 罗霁. 涂层损耗对硬质合金刀具磨损率变化影响的研究 [J]. 组合机床与自动化加工技术,2018,536(10):111-115.XU Ningping, LUO Ji. The research of effect of coating layer loss on the wear rate change of coated carbide tools [J]. Modular Machine Tool & Automatic Manufacturing Technique,2018,536(10):111-115. [7] 张丽秀, 申强, 张珂, 等. 基于ABAQUS的PDC钻头切削齿破岩仿真及热分析 [J]. 沈阳建筑大学学报(自然科学版),2018,34(5):912-920.ZHANG Lixiu, SHEN Qiang, ZHANG Ke, et al. Broken rock simulation and thermal analysis of PDC drill cutting edge based on ABAQUS [J]. Journal of Shenyang Jianzhu University(Natural Science),2018,34(5):912-920. [8] 王丽华, 杨家巍, 张永宏, 等. 基于堆叠降噪自编码的刀具磨损状态识别 [J]. 中国机械工程,2018,29(17):2038-2045.WANG Lihua, YANG Jiawei, ZHANG Yonghong, et al. Tool wear condition recognition based on SDAE [J]. China Mechanical Engineering,2018,29(17):2038-2045. [9] 程灿, 李建勇, 徐文胜, 等. 基于支持向量机与粒子滤波的刀具磨损状态识别 [J]. 振动与冲击,2018,37(17):56-63, 79.CHENG Can, LI Jianyong, XU Wensheng, et al. Tools wear state recognition based on support vector machine and particle filtering [J]. Journal of Vibration and Shock,2018,37(17):56-63, 79. [10] 查慧婷, 冯平法, 张建富, 等. 超声振动辅助划擦高体分铝基碳化硅的刀具磨损特性 [J]. 吉林大学学报(工学版),2019,202(2):458-465.ZHA Huiting, FENG Pingfa, ZHANG Jianfu, et al. Wear characteristics of cutting tools in ultrasonic vibration assisted scratching high volume fraction SiC particle reinforced aluminum matrix composites [J]. Journal of Jilin University(Engineering and Technology Edition),2019,202(2):458-465. [11] 陆峰, 查丽琼, 刘鲁生, 等. 基于硬脆材料加工的金刚石涂层硬质合金刀具制备及切削性能研究 [J]. 稀有金属与硬质合金,2018,227(4):82-86, 90.LU Feng, ZHA Liqiong, LIU Lusheng, et al. Research on preparation and cutting performance of diamond-coated cemented carbide tools used in hard brittle material machining [J]. Rare Metals and Cemented Carbides,2018,227(4):82-86, 90. [12] 向道辉, 郭振海, 冯浩人, 等. 微米及纳米金刚石涂层扁钻的制备及其切削性能 [J]. 表面技术,2018,47(8):122-129.XIANG Daohui, GUO Zhenhai, FENG Haoren, et al. Fabrication and cutting performance of micro- and nano-crystalline diamond coated spade drills [J]. Surface Technology,2018,47(8):122-129. [13] 孔维星, 巩春志, 田修波. 微细硬质合金刀具沉积金刚石薄膜的形核研究 [J]. 真空与低温,2019,25(3):170-177.KONG Weixing, GONG Chunzhi, TIAN Xiubo. Nucleation research of diamond films on tiny hard alloy milling cutters [J]. Vacuum and Cryogenics,2019,25(3):170-177. [14] 黄思思, 王杰, 胡茂琴, 等. 基于改进的径向基神经网络刀具磨损识别方法 [J]. 组合机床与自动化加工技术,2019,541(3):81-83.HUANG Sisi, WANG Jie, HU Maoqin, et al. A tool wear identification method based on the improved RBF neural network [J]. Modular Machine Tool & Automatic Manufacturing Technique,2019,541(3):81-83. [15] 王利强, 李绍朋, 吕志杰. 基于轮廓提取的刀具磨损量检测研究 [J]. 制造技术与机床,2019,689(11):88-92.WANG Liqiang, LI Shaopeng, LYU Zhijie. Study of tool wear extent monitoring based on contour extraction [J]. Manufacturing Technology & Machine Tool,2019,689(11):88-92. [16] 赵民, 张阔. 金刚石铣刀切削石材磨损试验研究 [J]. 机械设计与制造,2019,338(4):151-153,157.ZHAO Min, ZHANG Kuo. Experimental study on cutting stone wear of diamond milling cutters [J]. Machinery Design & Manufacture,2019,338(4):151-153,157. [17] 王宜豹, 黄楠, 刘鲁生, 等. 加工7075航空铝合金用金刚石涂层刀具的制备及其切削性能 [J]. 材料研究学报,2019,33(1):17-28.WANG Yibao, HUANG Nan, LIU Lusheng, et al. Preparation and cutting performance of diamond coated hard alloy cutting tools for 7075 aviation Al-alloy [J]. Chinese Journal of Materials Research,2019,33(1):17-28. [18] 赵亮, 程凯, 丁辉, 等. 超精密慢刀伺服金刚石车削加工的关键工艺问题研究 [J]. 制造技术与机床,2020,695(5):71-74.ZHAO Liang, CHENG Kai, DING Hui, et al. Investigation on key enabling process variables ultraprecision diamond turning using slow tool servo [J]. Manufacturing Technology & Machine Tool,2020,695(5):71-74. -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS