Preparing and characterizing Cr-coated diamond through one pot reaction in a vacuum reactor

-

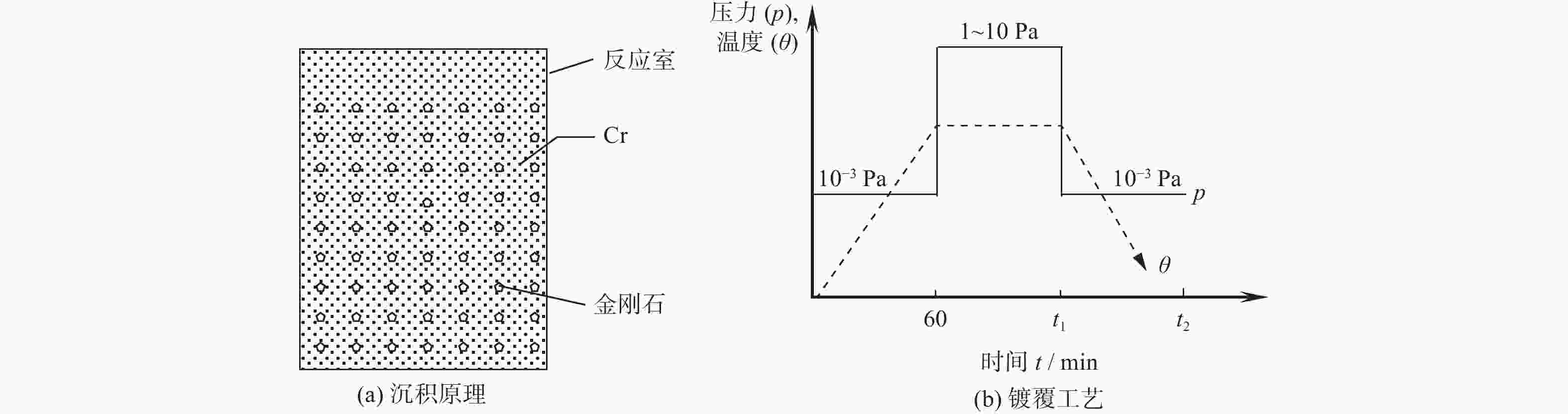

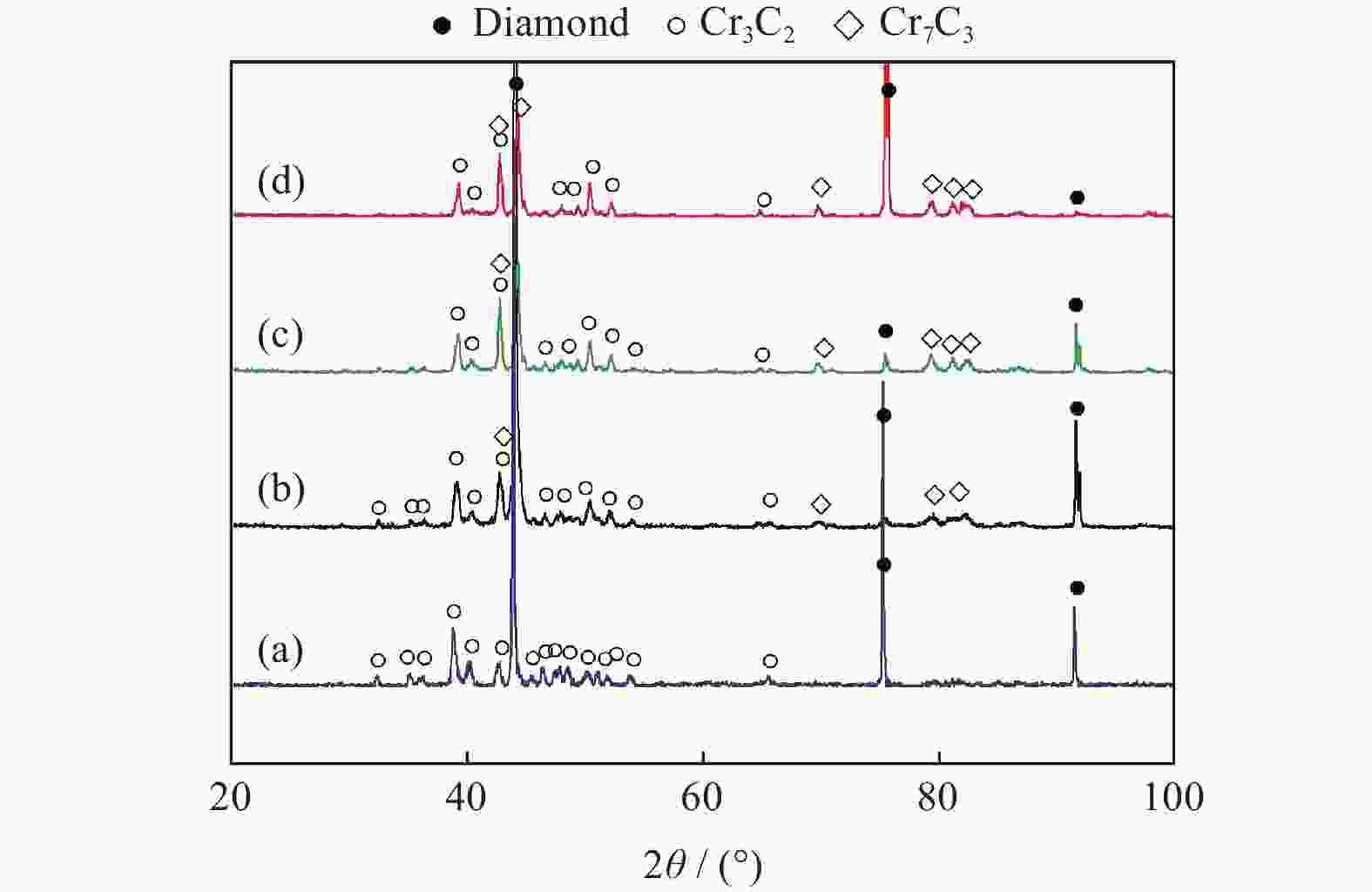

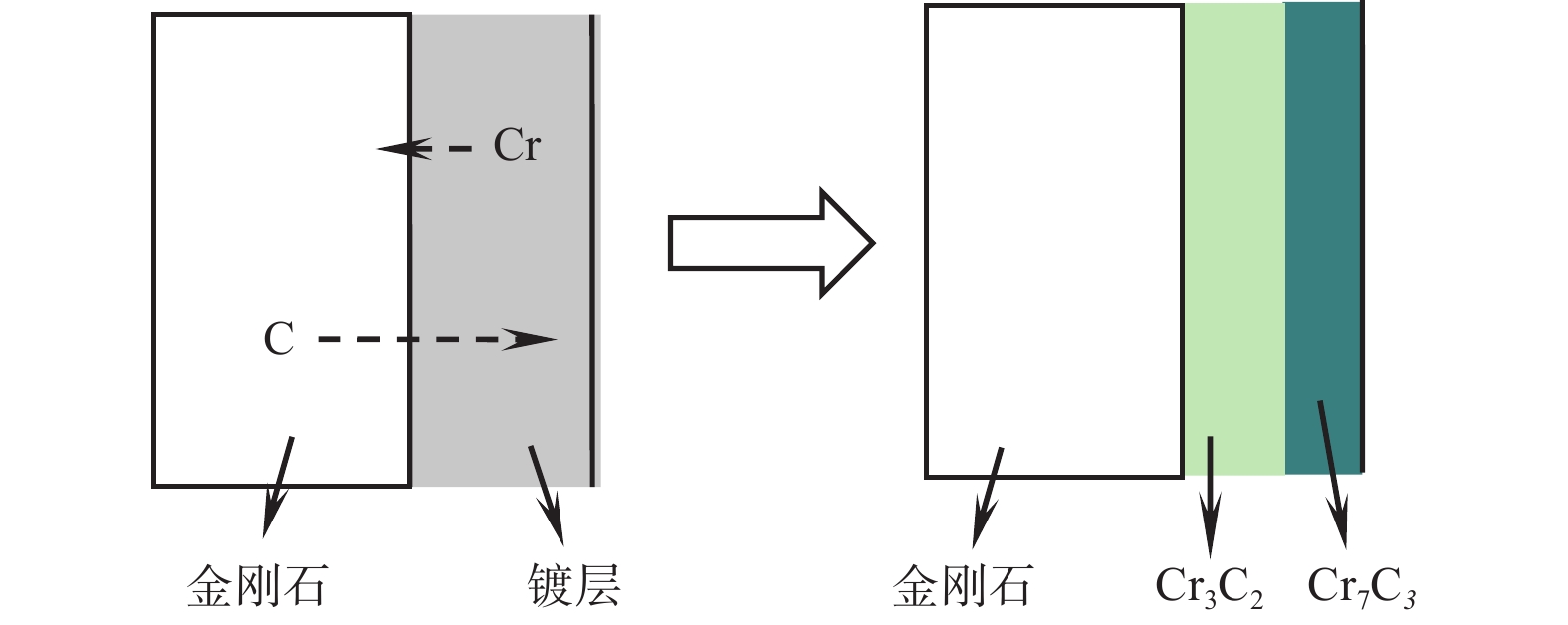

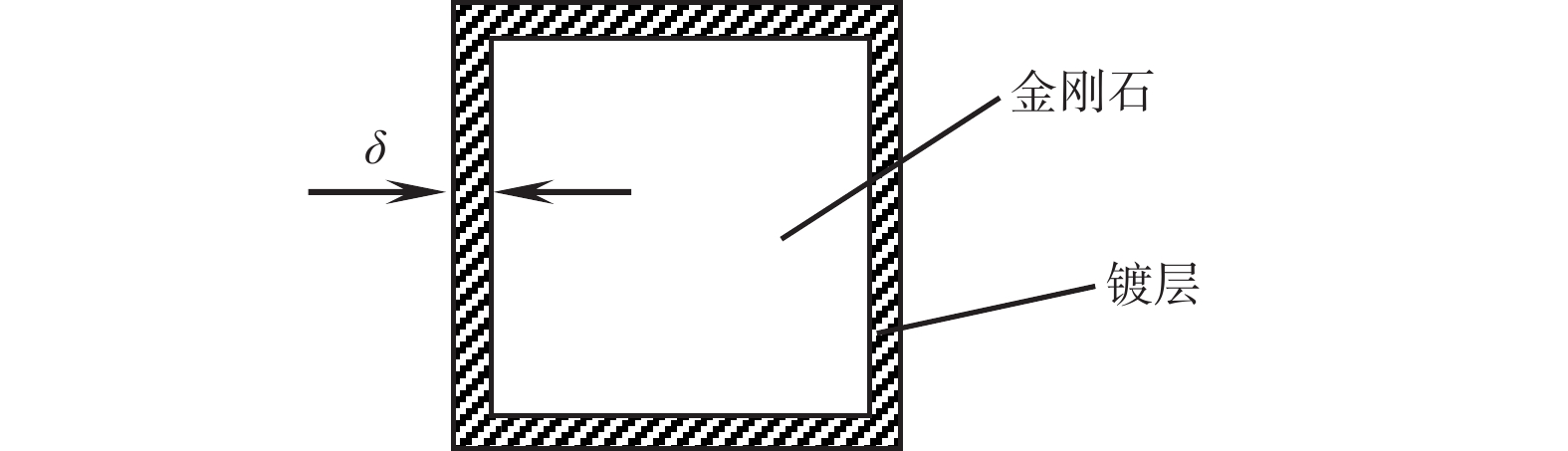

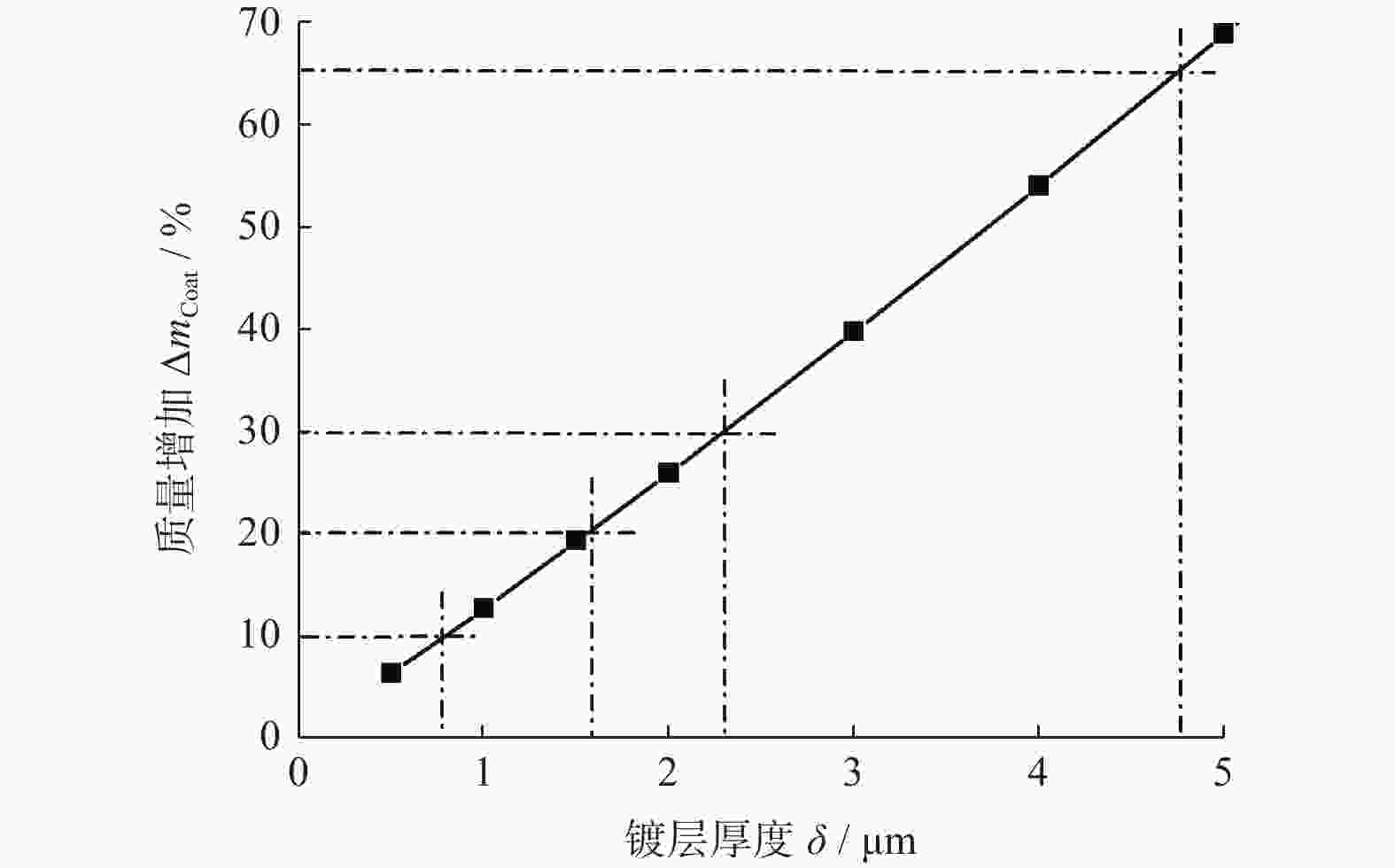

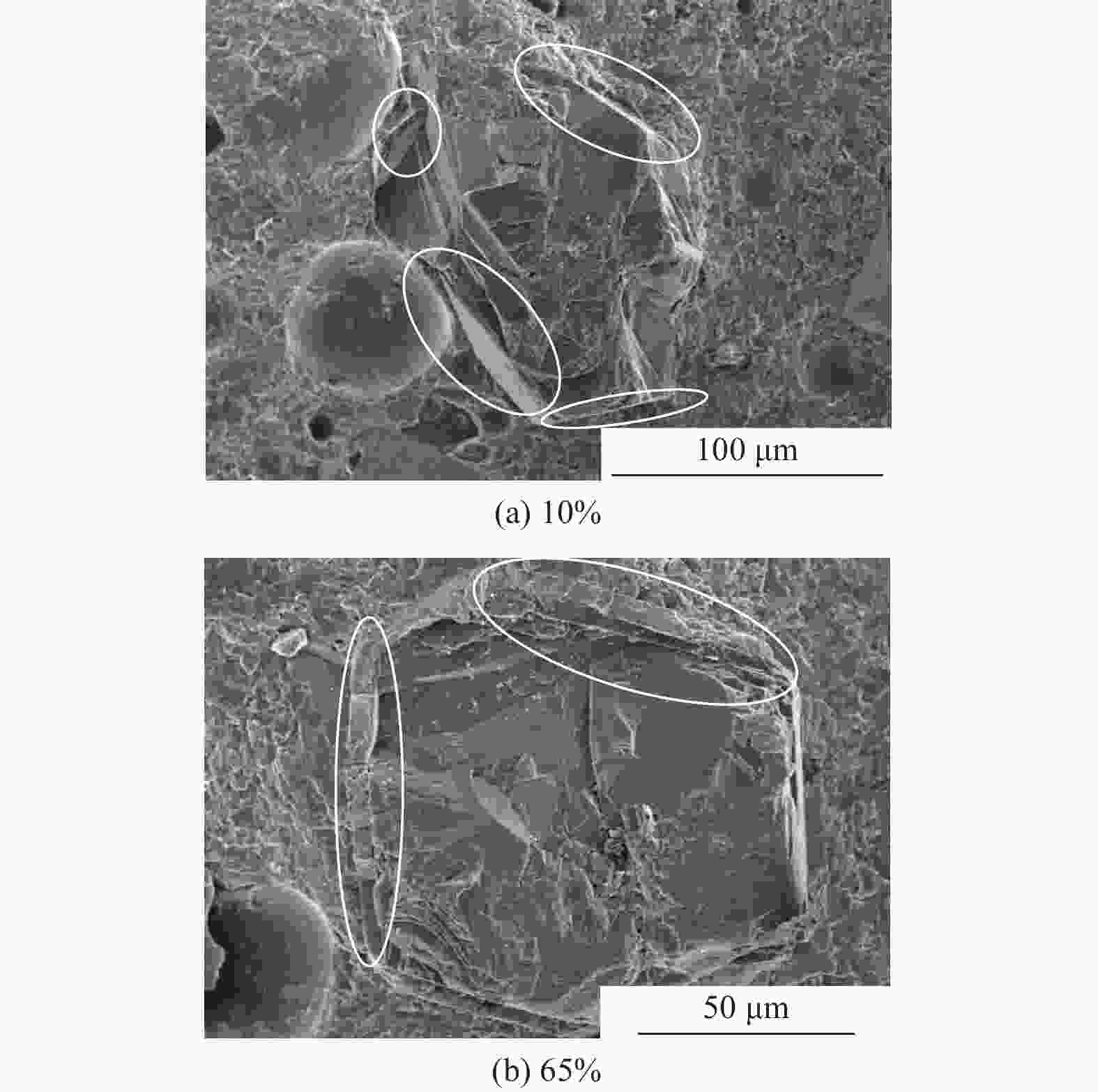

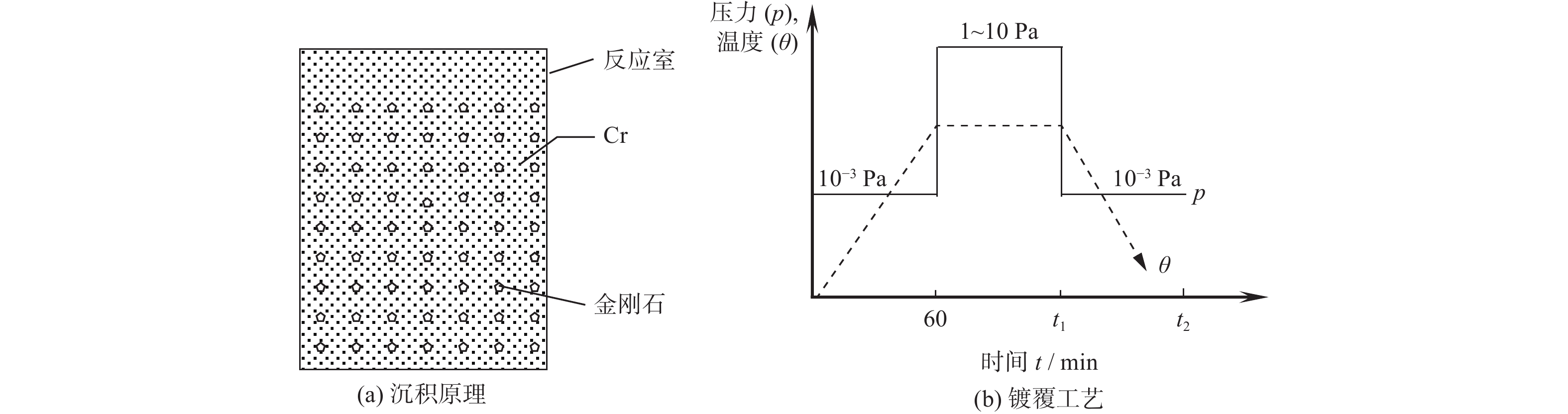

摘要: 采用真空微蒸发镀覆工艺制备不同镀层厚度的镀铬金刚石,对铬镀层的物相组成和镀层厚度进行分析和表征。结果表明:改变镀覆温度和保温时间,可控制镀铬金刚石的镀层厚度。镀层的物相组成可通过镀覆质量增加来控制:质量增加10%的铬镀金刚石,其镀层只出现Cr3C2相;质量增加为20%时,有少量Cr7C3出现。从金刚石基体到铬镀层,镀层结构由低Cr比例的碳化物向高Cr比例的碳化物逐渐过渡,即为Cr3C2/Cr7C3;在金刚石尺寸确定的情况下,使用理论分析镀层厚度与镀覆质量增加的关系,如质量增加10%和65%的金刚石对应的铬镀层厚度分别为0.77 μm和4.76 μm,此结果与试验观察相吻合。Abstract: Cr-coated diamonds with different coating weight gains were prepared by one pot reaction in a vacuum reactor, and the crystal phases and the thickness of the coatings were identified and analyzed. The results showed that the coating thickness varied with the temperatures and the holding time during coating. The crystal phases of the coating were related to the coating weight gains, which means that there appeared only Cr3C2 with 10% coating weight gain but Cr7C3 with 20% coating weight gain. It is also found that from the diamond surface to the Cr coating, the crystal phases are gradually transited from Cr3C2 to Cr7C3. For diamond with a certain particle size, there was a certain correspondence between the coating thickness and the coating weight gains. For example, when the coating thickness of the Cr-coated diamonds with 10% weight gains was 0.77 μm and that of diamonds with 65% coating was 4.76 μm, which was consistent with the SEM results.

-

Key words:

- Cr coating /

- diamond /

- the coating thickness

-

表 1 不同镀覆工艺条件的镀Cr金刚石

Table 1. Cr-coated diamond prepared under different parameters

序号 镀覆温度 θ / ℃ 镀覆时间 t / min 质量增加 w / % 1 850 20 10 2 850 240 20 3 900 120 30 4 950 240 65 表 2 不同质量增加对应的镀层厚度

Table 2. Coating thickness with different coating gains

序号 质量增加$ \Delta {m_{{\text{Coat}}}} $ / % 镀层厚度 δ / μm 1 10 0.77 2 20 1.58 3 30 2.29 4 65 4.76 -

[1] 边华英, 段爱萍, 王学涛. 金刚石磨具用陶瓷结合剂及其研究进展 [J]. 佛山陶瓷,2018,28(10):1-6. doi: 10.3969/j.issn.1006-8236.2018.10.002BIAN Huaying, DUAN Aiping, WANG Xuetao. Research and progress on vitrified bond for diamond tools [J]. Foshan Ceramics,2018,28(10):1-6. doi: 10.3969/j.issn.1006-8236.2018.10.002 [2] 刘洪成, 王琦, 王珏, 等. 金刚石工具结合剂的研究进展 [J]. 广州化工,2017,45(14):40-41,44. doi: 10.3969/j.issn.1001-9677.2017.14.015LIU Hongcheng, WANG Qi, WANG Yu, et al. Research progress on diamond tool binders [J]. Guangzhou Chemical Industry,2017,45(14):40-41,44. doi: 10.3969/j.issn.1001-9677.2017.14.015 [3] 常锐. 放电等离子体镀覆颗粒状金刚石和碳化硅的研究 [D]. 秦皇岛: 燕山大学, 2017.CHANG Rui. Study on surface treatment of granular diamond and silicon carbide by spark plasma coating [D]. Qinhuangdao: Yanshan University, 2017. [4] 吴燕平, 燕青芝. 金属结合剂金刚石工具研究进展 [J]. 金刚石与磨料磨具工程,2019,39(2):37-45. doi: 10.13394/j.cnki.jgszz.2019.2.0008WU Yanping, YAN Qingzhi. Research progress of metal bond diamond tools [J]. Diamond & Abrasives Engineering,2019,39(2):37-45. doi: 10.13394/j.cnki.jgszz.2019.2.0008 [5] 王艳辉, 李晓虎, 常锐, 等. 金刚石微粉表面镀覆对线锯的关键作用分析 [J]. 金刚石与磨料磨具工程,2013,33(3):26-30. doi: 10.13394/j.cnki.jgszz.2013.03.015WANG Yanhui, LI Xiaohu, CHANG Rui, et al. Effect of coated diamond micro powder on diamond wire saw manufacturing technology [J]. Diamond & Abrasives Engineering,2013,33(3):26-30. doi: 10.13394/j.cnki.jgszz.2013.03.015 [6] ZHANG X H, WANG Y H, LU J, et al. Wettability and reactivity in diamond–borosilicate glass system [J]. International Journal of Refractory Metals and Hard Materials,2010,28(2):260-264. doi: 10.1016/j.ijrmhm.2009.10.008 [7] ZHANG X H, WANG Y H, ZANG J B, et al. Improving oxidation resistance of diamond by adding silicon into diamond–borosilicate glass composites [J]. International Journal of Refractory Metals and Hard Materials,2011,29(4):495-498. doi: 10.1016/j.ijrmhm.2011.02.009 [8] WANG Y H, ZHANG X H, ZANG J B, et al. Influence of zinc particles on oxidation resistance of diamond/borosilicate glass composites [J]. Solid State Phenomena, 2011, 175: 8-12. [9] ZHANG X H, WANG Y H, ZANG J B, et al. Improvement of thermal stability of diamond by adding Ti during sintering of diamond/borosilicate glass composites [J]. Journal of the European Ceramic Society,2011,31(10):1897-1903. doi: 10.1016/j.jeurceramsoc.2011.04.009 [10] ZHANG X, WANG Y, ZANG J. Depression effects of Al on oxidation of diamond during sintering of diamond/borosilicate glass composites [J]. International Journal of Applied Ceramic Technology,2012,9(1):143-148. doi: 10.1111/j.1744-7402.2011.02620.x [11] 朱振东, 刘豪, 张甜, 等. 金刚石表面镀覆技术与应用的研究进展 [J]. 超硬材料工程,2021,33(3):28-32. doi: 10.3969/j.issn.1673-1433.2021.03.008ZHU Zhendong, LIU Hao, ZHANG Tian, et al. Research progress of plating technology on the diamond surface and its application [J]. Superhard Material Engineering,2021,33(3):28-32. doi: 10.3969/j.issn.1673-1433.2021.03.008 [12] CHANG R, ZANG J, WANG Y, et al. Preparation of the gradient Mo layers on diamond grits by spark plasma sintering and their effect on Fe-based matrix diamond composites [J]. Journal of Alloys and Compounds,2017,695:70-75. doi: 10.1016/j.jallcom.2016.10.172 [13] ZHANG X H, WANG Y H, ZANG J B, et al. Effect of Si coating on prevention of diamond degradation in diamond/glass composite [J]. Surface and Coatings Technology,2010,204(16/17):2846-2850. doi: 10.1016/j.surfcoat.2010.02.068 [14] CHANG R, ZANG J, WANG Y, et al. Study of Ti-coated diamond grits prepared by spark plasma coating [J]. Diamond and Related Materials,2017,77:72-78. doi: 10.1016/j.diamond.2017.06.004 [15] 邵浩明, 王进保, 李东平. Cr与金刚石界面碳化物形成机理研究 [J]. 超硬材料工程, 2008, 20(1): 19-21.SHAO Haoming, WANG Jinbao, LI Dongping. Research on formation mechanism of carbonide transition layer at the diamond interface with Cr [J]. Superhard Material Engineering, 2008, 20(1): 19-21. -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS