On-machine measurement and compensation machining for ultra-precision cutting of optical aspheric surface

-

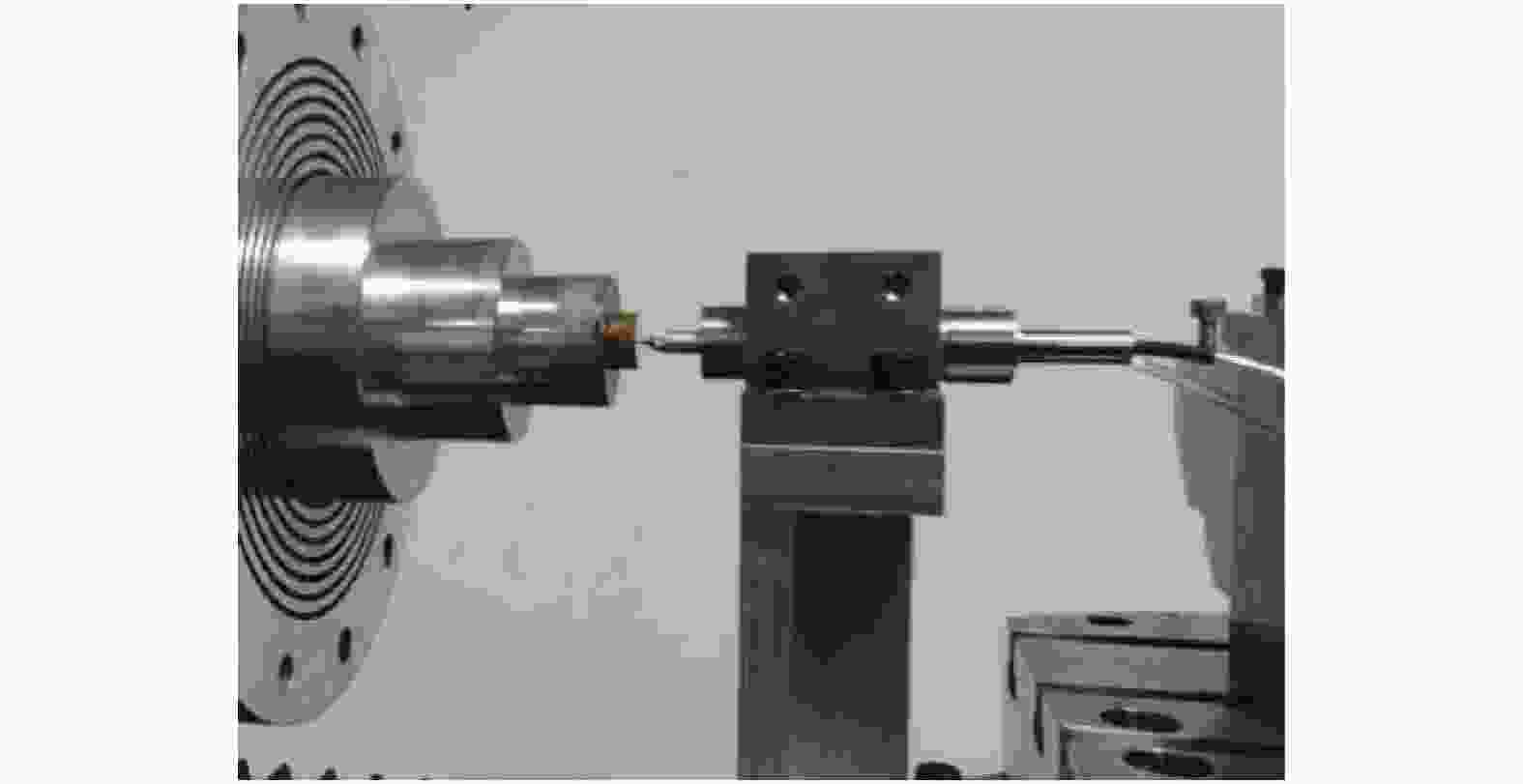

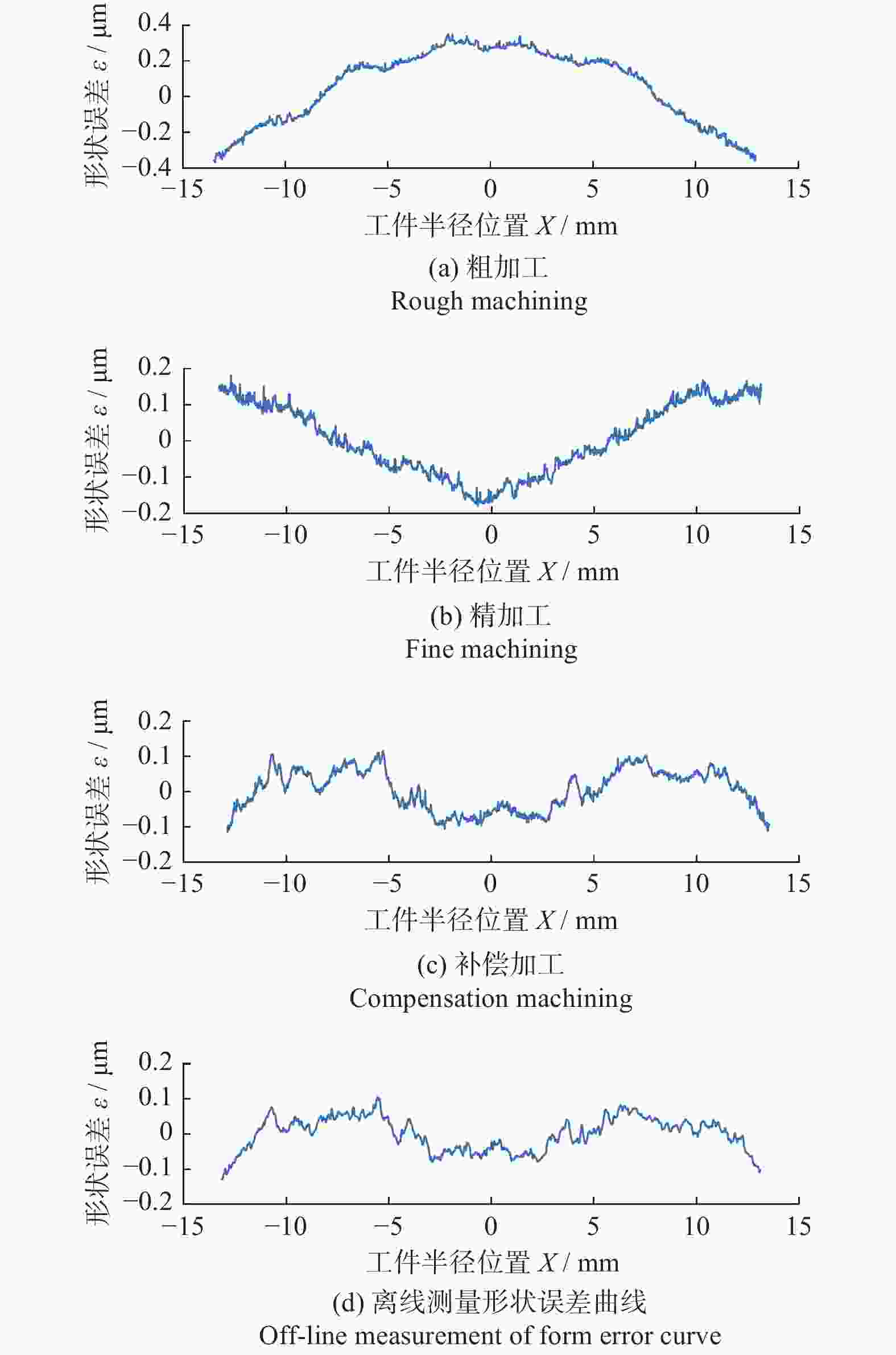

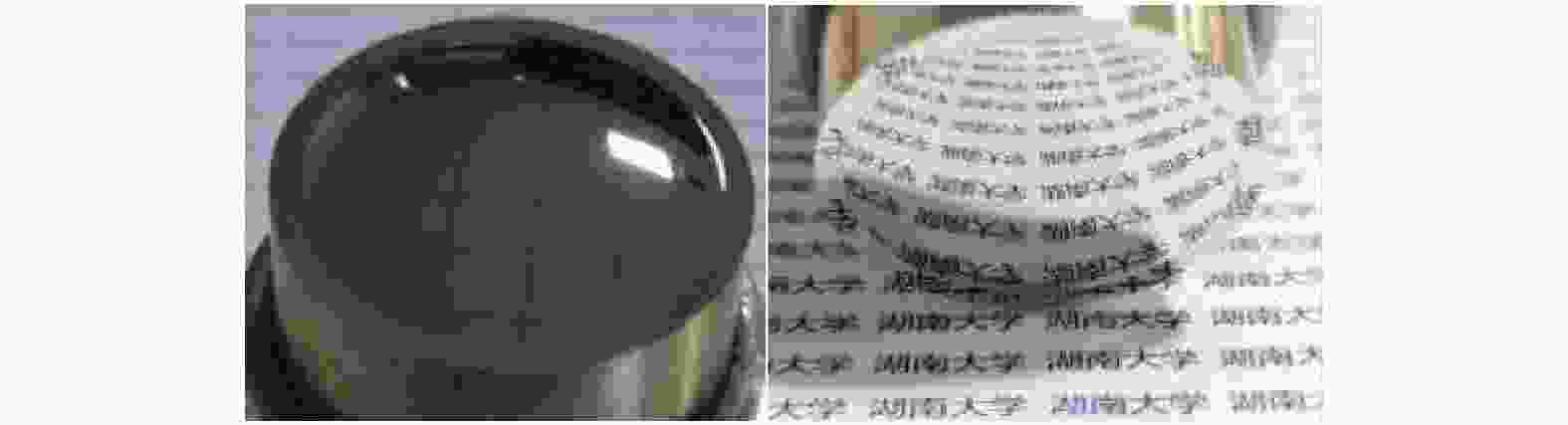

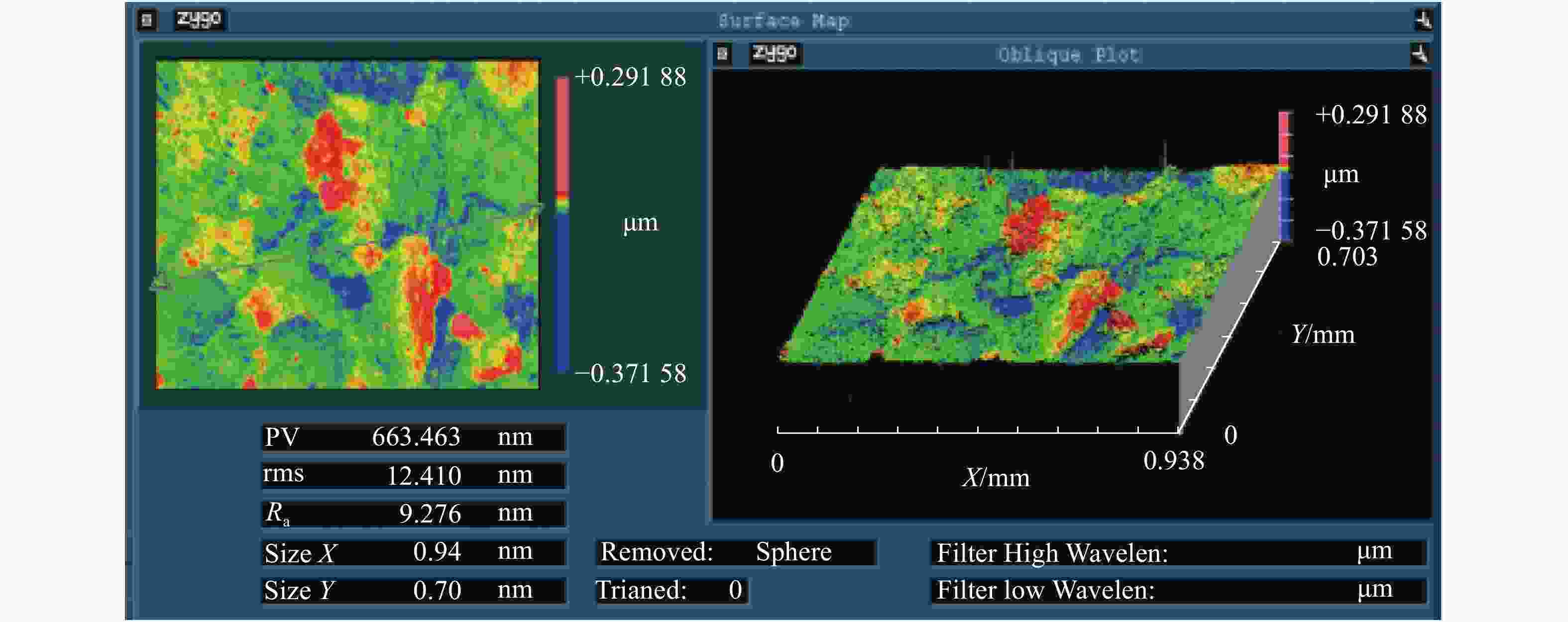

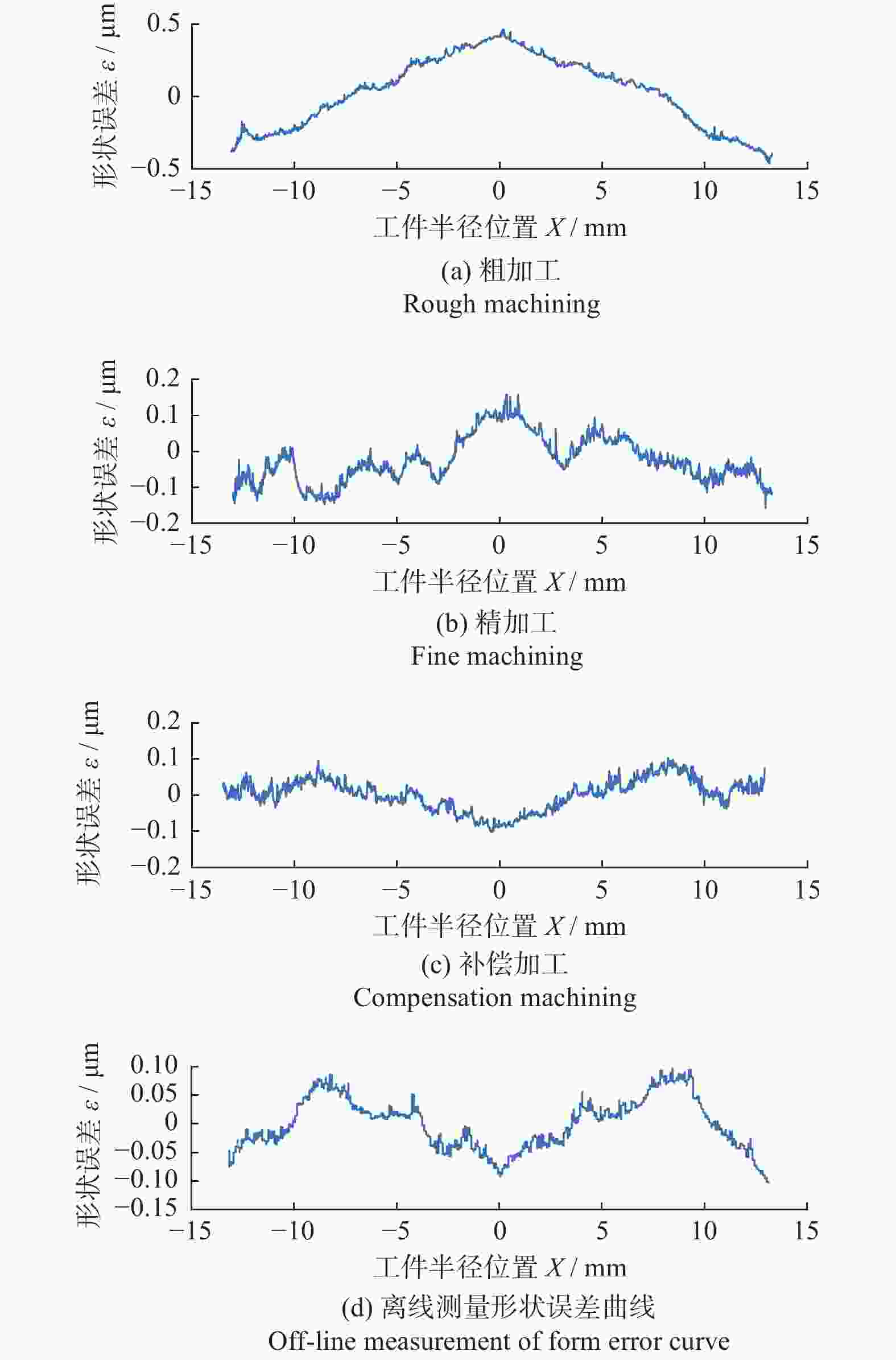

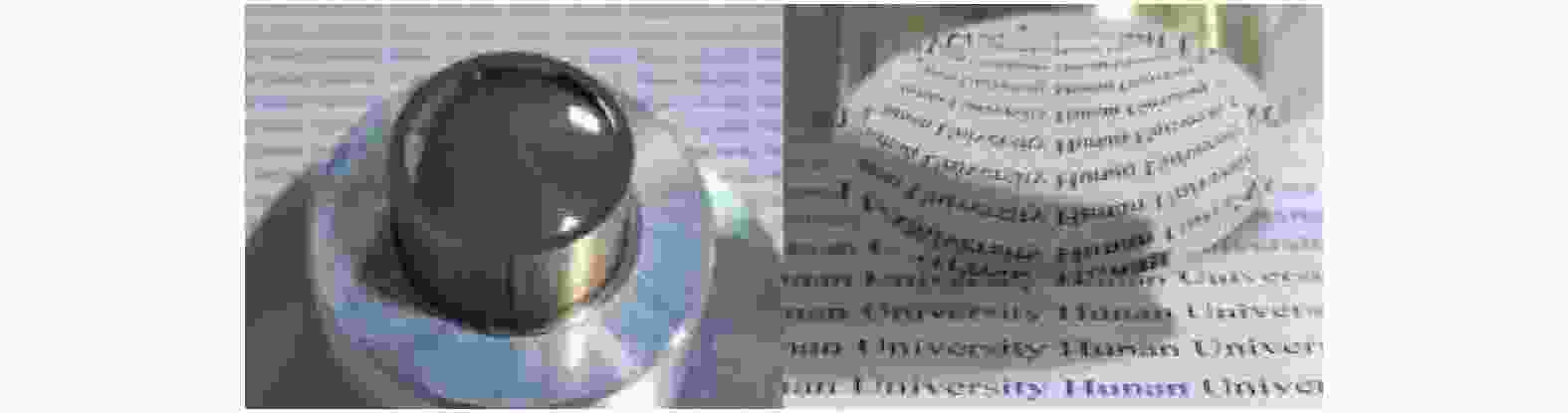

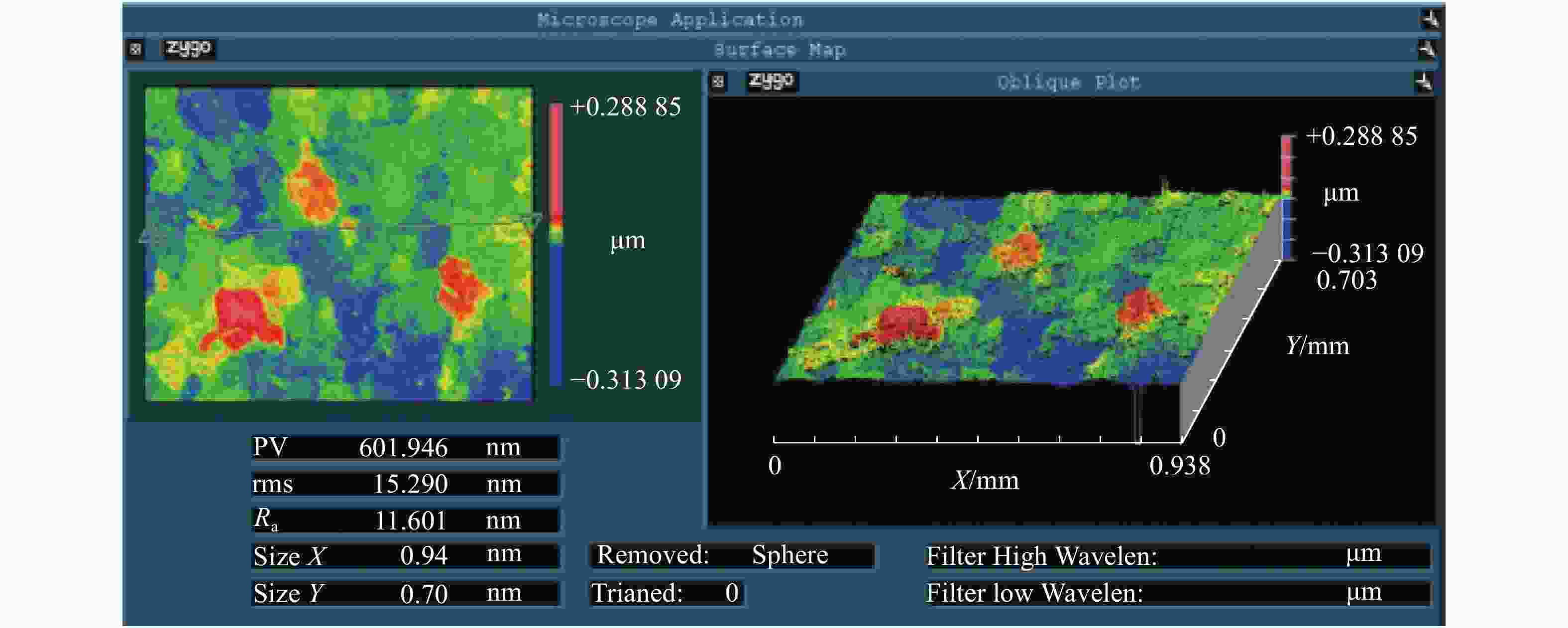

摘要: 开发一种采用接触式测头与电容式位移传感器相结合的在位测量装置及非球面测量与补偿加工软件,进行C3604黄铜球面及非球面的单点金刚石超精密切削加工,并开展在位测量及补偿加工试验。补偿加工后,经在位测量系统测量,球面面形精度PV达到231.4 nm,非球面面形精度PV达到206.3 nm;与离线测量结果比对,结果分别相差3.0 nm和7.0 nm,验证了在位测量系统测量的精确性和补偿加工的有效性。Abstract: An in-situ measurement device combining contact probe and capacitive displacement sensor is developed. An aspherical measurement and compensation machining software is also developed. The single point diamond ultra precision cutting experiments for C3604 brass spherical and aspherical surface are carried out. The in-situ measurement and compensation machining experiments are also carried out. After compensation machining, the spherical surface form accuracy PV reaches 231.4 nm, and the aspheric surface form accuracy PV reaches 206.3 nm. Compared with the off-line measurement results, the difference between the results is 3.0 nm, 7.0 nm respectively, the measuring accuracy of the in-situ measurement system and the validity of compensation machining are verified.

-

表 1 车削加工试验条件

Table 1. Experimental conditions for turning

参数名称数值 粗加工 精加工、补偿加工 工件转速 n / (r∙min−1) 800 800 进给速度 vf / (mm∙min−1) 6 2 切入量 a / μm 4 1 加工步距 l / μm 1 1 表 2 非球面系数

Table 2. Asphere coefficients

系数 数值 R −40 A2 −8.534 237×10−5 A6 −6.340 824×10−5 K −0.519 528 A4 −8.680 571×10−7 A8 −2.696 312×10−11 -

[1] DUNBABIN M,MARQUES L. Robots for environmental monitoring: Significant advancements and applications [J]. IEEE Robotics & Automation Magazine,2012,19(1):24-39. [2] 刘锋伟, 吴永前, 陈强,等. 大口径光学非球面镜先进制造技术概述 [J]. 光电工程,2020,47(10):65-87.LIU Fengwei, WU Yongqian, CHEN Qiang, et al. Overview of advanced manufacturing technology of large-aperture aspheric mirror [J]. Opto-Electronic Engineering,2020,47(10):65-87. [3] 辛企明. 光学塑料非球面技术的发展趋势 [J]. 激光与光电子学进展,2009,46(12):11-16.XIN Qiming. Trends of optical aspheric technologies [J]. Laser & Optoelectronics Progress,2009,46(12):11-16. [4] 闫如忠, 高潮, 王生泽, 等. 轴对称非球面在位测量系统的研究 [J]. 制造业自动化,2021,43(10):15-19,44.YAN Ruzhong, GAO Chao, WANG Shengze, et al. Study on the on-machine measurement of axisymmetric aspheric surface [J]. Manufacturing Automation,2021,43(10):15-19,44. [5] CHEN Y L, CAI Y, SHIMIZU Y, et al. On-machine measurement of microtool wear and cutting edge chipping by using a diamond edge artifact [J]. Precision Engineering,2016,43:462-467. doi: 10.1016/j.precisioneng.2015.09.011 [6] YIN Z, CHAI N, WANG S, et al. Single probe shear scanning method for on-machine measurement of an optical profile [J]. Applied Optics,2020,59(15):4718-4731. doi: 10.1364/AO.391512 [7] WANG S, ZHAO Q, PAN Y, et al. Ultra-precision raster grinding biconical optics with a novel profile error compensation technique based on on-machine measurement and wavelet decomposition [J]. Journal of Manufacturing Processes,2021,67:128-140. doi: 10.1016/j.jmapro.2021.04.059 [8] 陈逢军, 尹韶辉, 余剑武, 等. 一种超精密非球面在位测量方法 [J]. 激光与光电子学进展,2012,49(7):108-111.CHEN Fengjun, YIN Shaohui, YU Jianwu, et al. An ultra-precision on-machine measurement method of aspheric surface [J]. Laser & Optoelectronics Process,2012,49(7):108-111. [9] 张祥朝, 徐敏. 面向精密制造的光学自由曲面在位偏折测量技术 [J]. 光电工程,2020,47(8):74-83.ZHANG Xiangchao, XU Min. In-situ deflectometric measurement of optical surfaces for precision manufacturing [J]. Opto-Electronic Engineering,2020,47(8):74-83. [10] 朱吴乐. 金刚石切削微纳结构的高精度在位测量关键技术研究 [D]. 杭州: 浙江大学, 2016.ZHU Wule. Research on key technologies of in-situ precision measurement for diamond-machined micro/nano-structures [D]. Hangzhou: Zhejiang University, 2016. [11] SHIBUYA A, GAO W, YOSHIKAWA Y, et al. Profile measurements of micro-aspheric surfaces using an air-bearing stylus with a microprobe [J]. International Journal of Precision Engineering and Manufacturing,2007,8(2):26-31. -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS