Effect of interface microstructure on properties of polycrystalline diamond composites

-

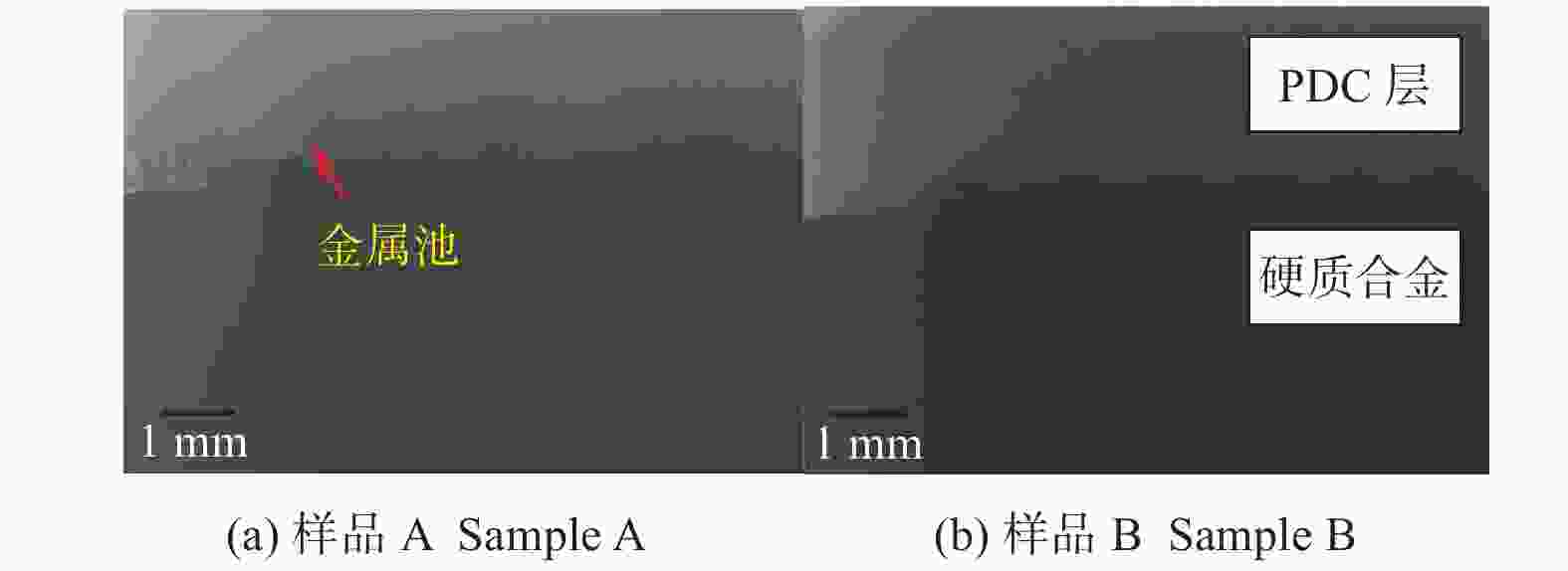

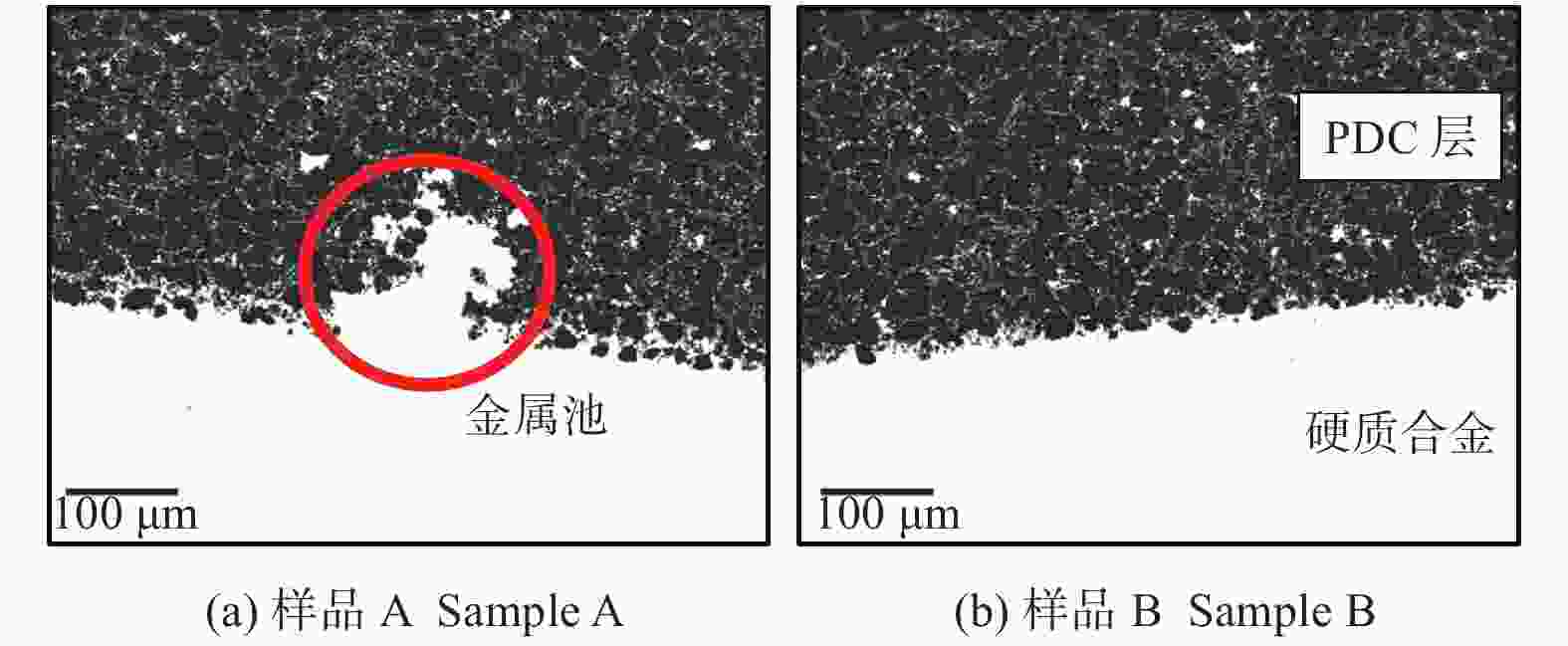

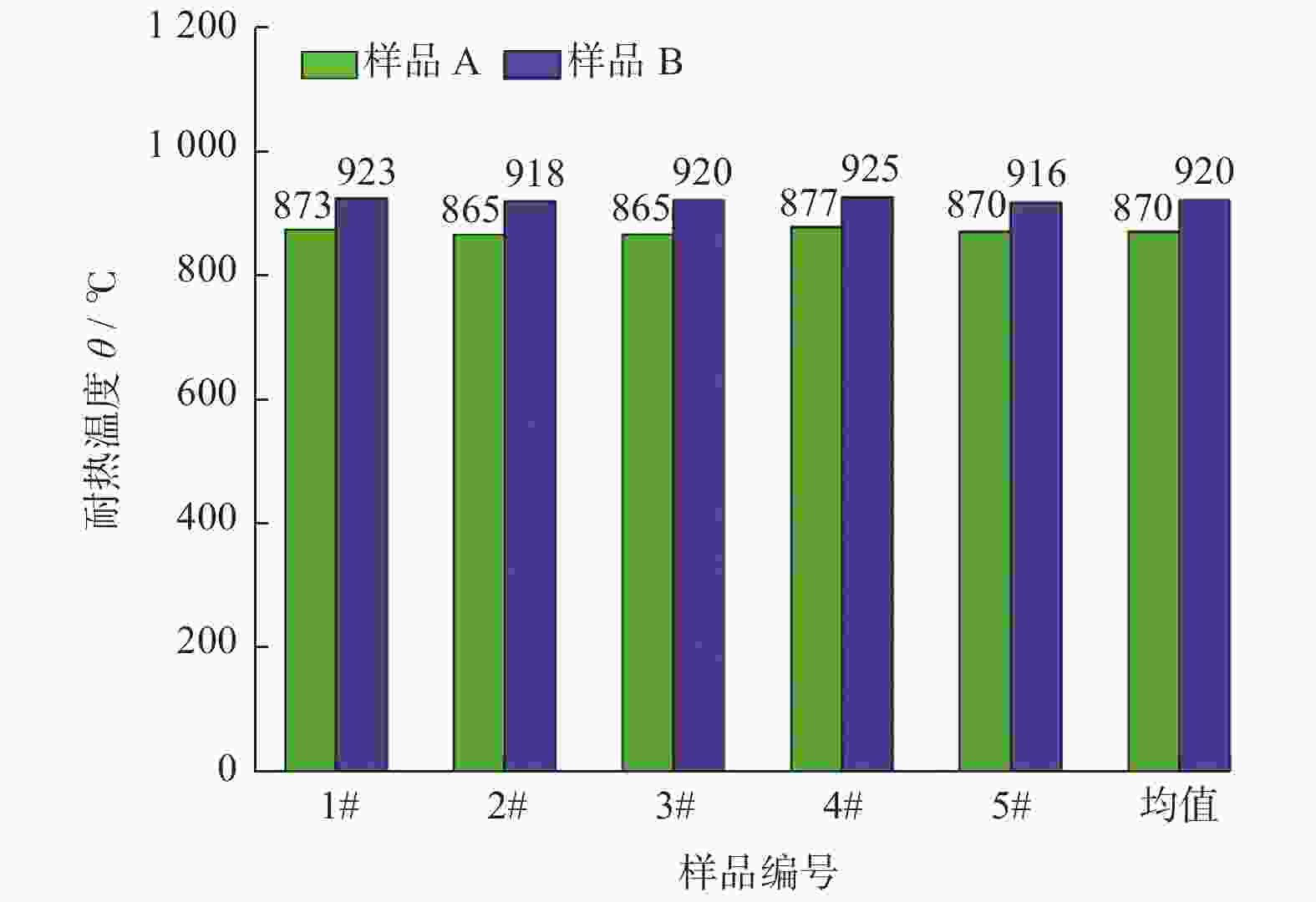

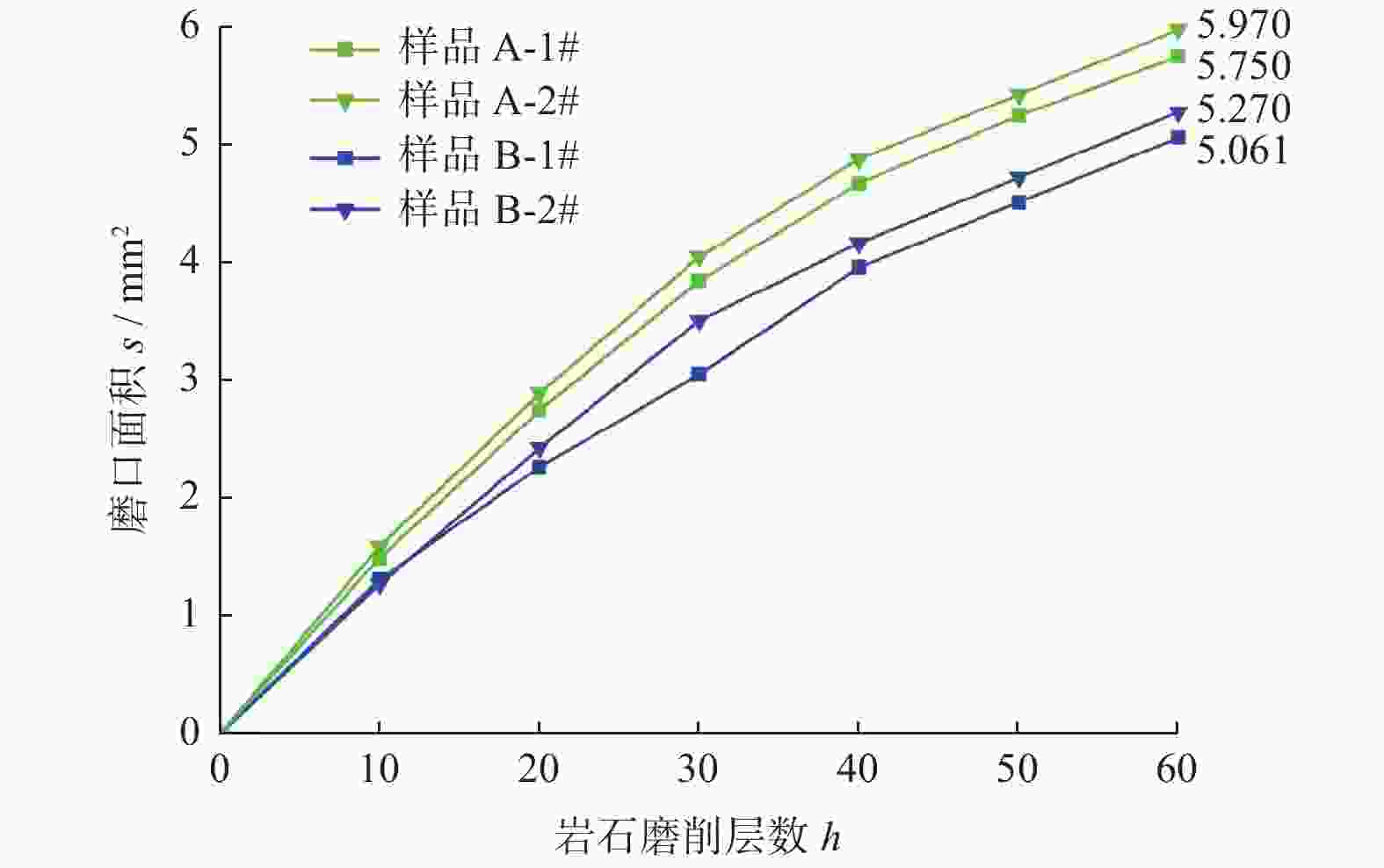

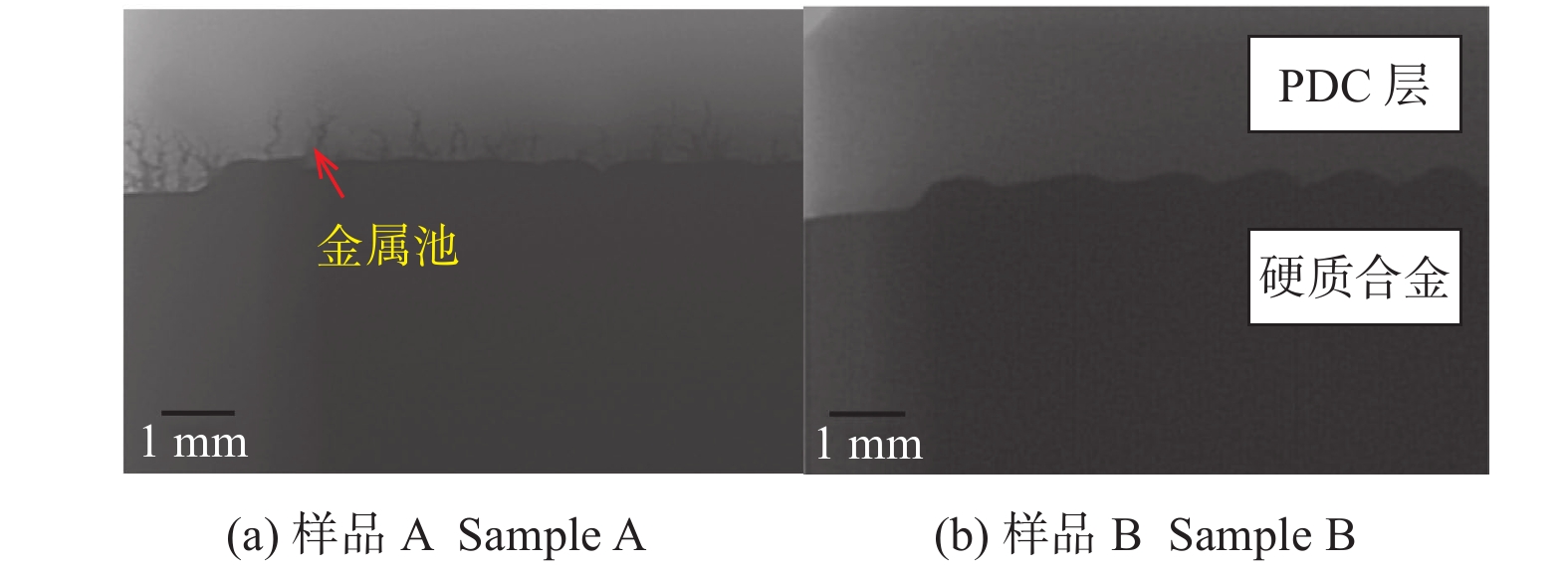

摘要: 以硬质合金基体及优选的主晶为25 μm的金刚石颗粒为原料,在2种工艺下用国产铰链式六面顶压机高温高压制备聚晶金刚石复合片(PDC),研究PDC界面处微观结构对其性能的影响。结果表明:工艺1制备的PDC界面处存在类树枝状枝晶金属池,其是硬质合金中的金属元素向聚晶金刚石层方向迁移形成的,主要元素为C、W、Co;而工艺2制备的PDC中不存在此类现象。工艺1制备的PDC的耐热温度为870 ℃,抗冲击等级为32,磨口面积为5.860 mm2;工艺2制备的PDC的耐热温度为920 ℃,抗冲击等级为45,磨口面积为5.166 mm2。工艺2制备的PDC相对于工艺1制备的PDC,其耐热温度、抗冲击性能和耐磨性能分别提高50 ℃、40.6%和11.8%。

-

关键词:

- 聚晶金刚石复合片(PDC) /

- 金属池 /

- 耐热温度 /

- 抗冲击性 /

- 耐磨性

Abstract: The cemented carbide matrix and the preferred main crystal of 25 μm diamond particles as raw materials, the polycrystalline diamond composites (PDC) was prepared by domestic hinge-type cubic-anvil press at high temperature and high pressure (HPHT) under two processes. Effect of microstructure at PDC interface on its properties was studied. The results show that there is a dendrite-like growth metal pool at the interface of PDC prepared by process 1, which is formed by the migration of metal elements in cemented carbide to polycrystalline diamond layer, and the main elements are C, W and Co. This phenomenon does not exist in the interface of PDC prepared by process 2. The heat resistance temperature is 870 ℃, the impact resistance grade is 32 and the grinding area is 5.860 mm2 of PDC prepared by process 1. The heat resistance temperature is 920 ℃, the impact resistance grade is 45, and the grinding area is 5.166 mm2 of PDC prepared by process 2. Compared with the PDC prepared by process 1, the heat resistance, the impact resistance and the wear resistance of the PDC prepared by process 2 are increased by 50 ℃, 40.6% and 11.8%, respectively. -

表 1 样品A界面附近金属池的元素组成

Table 1. Elemental compositions of metal pool near the interface of sample A

元素

元素质量分数 ω / %

原子质量分数 ωat / %

C

17.83

71.51

Co

12.51

10.23

W

69.66

18.26 -

[1] 郑艳彬, 姜志刚, 朱品文. 聚晶金刚石的高温高压制备及其性能研究进展 [J]. 材料导报,2016(23):81-86.ZHENG Yanbin, JIANG Zhigang, ZHU Pinwen. Preparation and properties of polycrystalline diamond via high temperature and high pressure [J]. Materials Review,2016(23):81-86. [2] 孙伟, 赵海峰, 张天翔, 等. 提高金刚石复合片抗冲击性能的试验研究 [J]. 钻采工艺,2018,41(6):87-89,105.SUN Wei, ZHAO Haifeng, ZHANG Tianxiang, et al. Study on improving impact resistance of diamond composite [J]. Drilling & Production Technology,2018,41(6):87-89,105. [3] 王坤. 液相烧结法聚晶金刚石微观结构及其力学性能研究 [J]. 陶瓷,2019(8):53-62.WANG Kun. Study on microstructure and mechanical properties of polycrystalline diamond by liquid sintering method [J]. Ceramics,2019(8):53-62. [4] 张启斌. 聚晶金刚石(PCD)刀具有刃磨及其刃磨砂轮的研究[D]. 大连: 大连理工大学, 1998.ZHANG Qibin. Research on polycrystalline diamond (PCD) cutter with grinding wheel and grinding wheel[D]. Dalian: Dalian University of Technology, 1998. [5] CITTEL H. Cutting tool materials for high performance machining [J]. Industrial Diamond Review,2001,61(588):17, 20-21. [6] ARSECULARATNE J, ZHANG L, MONTROSS C. Wear and tool life of tungsten carbide, PCBN and PCD cutting tools [J]. International Journal of Machine Tools & Manufacture,2006,46(5):482-491. [7] 张健琼, 姚一飞, 沈翔, 等. 合成温度对聚晶金刚石的影响 [J]. 金刚石与磨料磨具工程,2009(1):36-38, 48.ZHANG Jianqiong, YAO Yifei, SHEN Xiang, et al. Influence of synthesis temperature on polycrystalline diamond [J]. Diamond & Abrasives Engineering,2009(1):36-38, 48. [8] 衡军, 骈小璇, 史春燕, 等. 不同黏结剂聚晶金刚石晶粒界面研究进展 [J]. 金刚石与磨料磨具工程,2017,37(5):74-78, 92.HENG Jun, PIAN Xiaoxuan, SHI Chunyan, et al. Research status of grain interface in polycrystalline diamond with different binders [J]. Diamond & Abrasives Engineering,2017,37(5):74-78, 92. [9] 张喆. 减少聚晶金刚石复合片残余应力的若干途径 [J]. 超硬材料工程,2016,28(5):49-53. doi: 10.3969/j.issn.1673-1433.2016.05.010ZHANG Zhe. Ways of decreasing the residual stress in polycrystalline diamond compacts [J]. Superhard Material Engineering,2016,28(5):49-53. doi: 10.3969/j.issn.1673-1433.2016.05.010 [10] 邵华丽, 王海阔, 徐三魁, 等. 聚晶金刚石的热稳定性研究进展 [J]. 材料导报,2015(15):81-84.SHAO Huali, WANG Haikuo, XU Sankui, et al. Research progress of thermal stability for polycrystalline diamond [J]. Materials Review,2015(15):81-84. [11] 彭玉柏. 超高压−高温复合PDC制备过程中硬质合金基体显微组织结构和性能的变化 [J]. 硬质合金,2020,37(5):345-349.PENG Yubo. Changes of microstructure and properties of cemented carbide substrate during the preparation of ultra-high pressure and high temperature composite PDC [J]. Cemented Carbide,2020,37(5):345-349. [12] 赵东鹏, 方海江, 王勇峰, 等. 一种微观结构均匀的聚晶金刚石复合片的制备方法及产物: 201910459388.4 [P]. 2019-08-06.ZHAO Dongpeng, FANG Haijiang, WANG Yongfeng, et al. A kind of preparation method and product of polycrystalline diamond composite sheet with uniform microstructure: 201910459388.4 [P]. 2019-08-06. -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS