Effect of sodium dodecyl benzene sulfonate on vitrified bond and dispersion of diamond

-

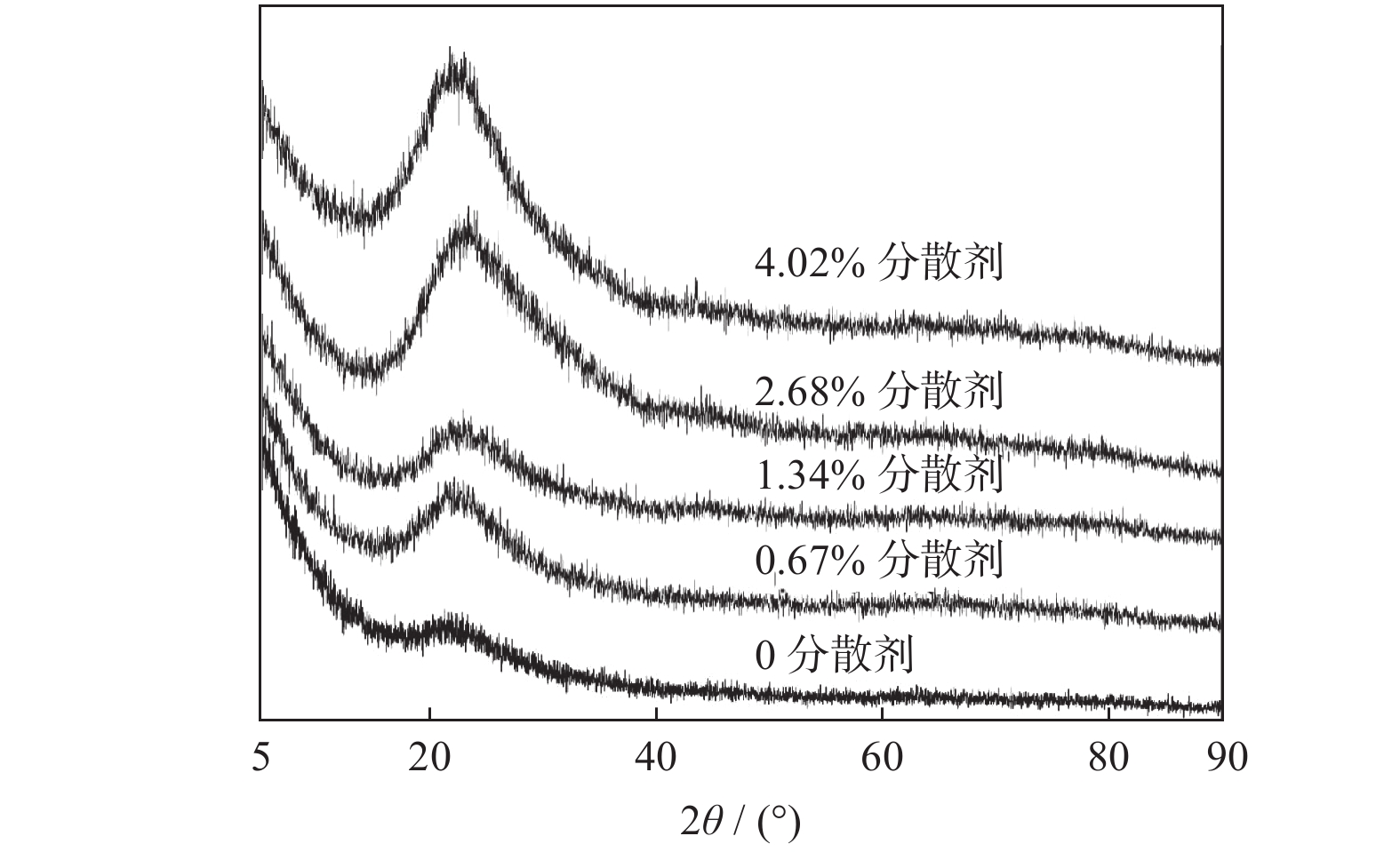

摘要: 采用溶胶–凝胶法制备陶瓷结合剂粉末和陶瓷结合剂/金刚石混合粉末以及相应的块体材料。研究分散剂(十二烷基苯磺酸钠)质量分数为0~4.02%时,其对陶瓷结合剂物相、耐火度、弯曲强度和热膨胀系数等的影响,以及其对M2.5/5金刚石在陶瓷结合剂/金刚石混合粉末中分散性的影响。结果表明:分散剂质量分数为1.34%时,陶瓷结合剂的耐火度、弯曲强度和热膨胀系数与未添加分散剂时相比未发生明显变化,其中耐火度为700 ℃、弯曲强度为45 MPa 、热膨胀系数为4.3×10−6 ℃−1;当分散剂的质量分数从1.34%增加至4.02%时,陶瓷结合剂的耐火度降至600 ℃,弯曲强度降至28 MPa,热膨胀系数增至7.5×10−6 ℃−1;分散剂质量分数为1.34%时,M2.5/5金刚石均匀分散在陶瓷结合剂/金刚石复合材料中,且未引起复合材料的性能变化。Abstract: Vitrified bonds and the mixed powders of diamond and vitrified bonds are prepared by sol-gel and corresponding bulk composites are fabricated. The effect of mass fraction of dispersant (sodium dodecyl benzene sulfonate) ranged from 0 to 4.02% on property of vitrified bond is studied, including composition phase of vitrified bond, refractoriness, bending strength and thermal expansion coefficient. The dispersibility of M2.5/5 diamond dispersed in the mixed powders is investigated. The result reveals that when the mass fraction of dispersant was 1.34%, refractoriness of 700 ℃, bending strength of 45 MPa and coefficient of thermal expansion of 4.3×10−6 ℃−1 have no change compared with that without addition of dispersant. Besides, with the dispersant increasing from 1.34% to 4.02% the refractoriness of vitrified bond prepared by sol-gel technique decreases to 600 ℃ and bending strength decreases to 28 MPa. The thermal expansion coefficient of vitrified bond increases to 7.5×10−6 ℃−1. The research demonstrates that the addition of 1.34% dispersant can realize uniform dispersion of M2.5/5 diamond powder in vitrified bond /diamond composites without causing change in properties of the composites.

-

表 1 试验用原材料组分

Table 1. Components of starting materials utilized in the experiment

组分 质量分数 wt / % SiO2 72.22 B2O3 2.78 Na2O 5.56 Al2O3 8.33 金刚石 11.11,0 十二烷基苯磺酸钠 0,0.67,1.34,2.68,4.02 表 2 不同质量分数分散剂制备陶瓷结合剂样条的硬度和密度

Table 2. Hardness and density of vitrified bonds with different mass fractions of dispersant

分散剂质量分数 w / % 洛氏硬度 HRC 密度 ρ / (g·cm−3) 0 83.2 2.25 0.67 85.8 2.22 1.34 78.1 2.21 2.68 40.3 1.22 4.02 28.4 < 1.00 -

[1] BRINKSMEIER E, MUTLUGÜN Y, KLOCKE F, et al. Ultra-precision grinding [J]. CIRP Annals-Manufacturing Technology,2010,59(2):652-671. doi: 10.1016/j.cirp.2010.05.001 [2] WANG S, ZHAO Q, GUO B, et al. Ultra-precision raster grinding of monocrystalline silicon biconical free-form optics using arc-shaped diamond grinding wheels [J]. Journal of Manufacturing Processes,2020,58:1064-1074. doi: 10.1016/j.jmapro.2020.09.020 [3] ZHANG C, GUO B, ZHAO Q, et al. Ultra-precision grinding of AlON ceramics: Surface finish and mechanisms [J]. Journal of the European Ceramic Society,2019,39(13):3668-3676. doi: 10.1016/j.jeurceramsoc.2019.05.005 [4] RAO Z, XIAO G, ZHAO B, et al. Effect of wear behaviour of single mono- and poly-crystalline cBN grains on the grinding performance of Inconel 718 [J]. Ceramics International,2021,47:17049-17056. doi: 10.1016/j.ceramint.2021.03.012 [5] DENKENA B, KöHLER J, VENTURA C E H. Influence of grinding parameters on the quality of high content PCBN cutting inserts [J]. Journal of Materials Processing Technology,2014,214(2):276-284. doi: 10.1016/j.jmatprotec.2013.09.013 [6] GUO B, ZHAO Q, FANG X. Precision grinding of optical glass with laser micro-structured coarse-grained diamond wheels [J]. Journal of Materials Processing Technology,2014,214(5):1045-1051. doi: 10.1016/j.jmatprotec.2013.12.013 [7] ONWUKA G, ABOU-EL-HOSSEIN K. Surface roughness in ultra-high precision grinding of BK7 [J]. Procedia CIRP,2016,45:143-146. doi: 10.1016/j.procir.2016.03.023 [8] AIDA H, KIM S, IKEJIRI K, et al. Precise mechanical polishing of brittle materials with free diamond abrasives dispersed in micro-nano-bubble water [J]. Precision Engineering,2015,40:81-86. doi: 10.1016/j.precisioneng.2014.10.008 [9] ANDO T, MIKKA N G, ROBIN E R. Chemical modification of diamond surfaces using a chlorinated surface as an intermediate state [J]. Diamond and Related Materials,1996,5(5):1136-1142. [10] MOCHALIN V, GOGOTSI Y. Nanodiamond-polymer composites [J]. Diamond and Related Materials,2015,58:161-171. doi: 10.1016/j.diamond.2015.07.003 [11] LIN T, LIU S, JI Z, et al. Vitrified bond diamond grinding wheel prepared by gel-casting with 3D printing molds [J]. Diamond and Related Materials,2020,108:107917-107923. doi: 10.1016/j.diamond.2020.107917 [12] ZHANG W, LIU X, CHEN S, et al. Variations in structure and properties of vitrified bonds and vitrified diamond composites prepared by sol-gel and melting methods at different sintering temperature [J]. Ceramics International,2020,46(13):21202-21210. doi: 10.1016/j.ceramint.2020.05.202 [13] 赵东鹏. 超精磨陶瓷结合剂纳米金刚石磨具的研制 [D]. 秦皇岛: 燕山大学, 2013.ZHAO Dongpeng. Research of vitrified-bonded nanodiamond wheels for ultra-precision grinding [D]. Qinhuangdao: Yanshan University, 2013. [14] 李亚朋. 高分子网络凝胶法陶瓷结合剂微纳米金刚石磨具的制备 [D]. 秦皇岛: 燕山大学, 2016.LI Yapeng. Preparation on micro/nanodiamond tools bonded with ceramic abrasive by polymer network sol-gel method [D]. Qinhuangdao: Yanshan University, 2016. [15] 胡伟达. 溶胶凝胶法制备陶瓷结合剂金刚石砂轮的研究 [D]. 长沙: 湖南大学, 2013.HU Weida. Study on preparation vitrified bond diamond grinding wheel by sol-gel method [D]. Changsha: Hunan University, 2013. [16] CHANG S Y, RING T A. Map of gel times for three phase region tetraethoxysilane, ethanol and water [J]. Journal of Non-crystalline Solids, 1992, 147/148: 56–61. [17] GALLYAMOVA R, DOKICHEV V, SAFIULLIN R, et al. The effect of the concentration of water in the silica sol-gel solution on the formation of an oxide film on the surface of carbon fibers [J]. Materials Today: Proceedings,2021,38:1584-1587. doi: 10.1016/j.matpr.2020.08.156 [18] DOLININA E S, KRAEV A S, PARFENYUK E V. Effect of sol-gel synthesis conditions on the physical properties of silica hydrogels [J]. Mendeleev Communications,2020,30(6):812-814. doi: 10.1016/j.mencom.2020.11.041 [19] 朱昌洪. 微细金刚石化学复合镀工艺研究 [D]. 南京: 南京航空航天大学, 2011.ZHU Changhong. Study on chemical composite plating technology of fine diamond [D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2011. [20] JOSHI R, CHHIBBER R. Effect of SiO2/B2O3 ratio on the thermophysical and wetting properties of borosilicate glass sealant for glass-metal joint [J]. Journal of Materials Processing Technology,2018,259:186-194. doi: 10.1016/j.jmatprotec.2018.04.028 [21] CUI L, HAO X, TANG Y, et al. Effect of B2O3 on physical properties of LZAS vitrified bond and mechanical properties of diamond composites [J]. International Journal of Refractory Metals & Hard Materials,2015,52:50-54. [22] EL-EGILI K. Infrared studies of Na2O–B2O3–SiO2 and Al2O3–Na2O–B2O3–SiO2 glasses [J]. Physica B,2003,325:340-348. doi: 10.1016/S0921-4526(02)01547-8 [23] 谭刚. 硅晶圆CMP抛光速率影响因素分析 [J]. 微纳电子技术,2007,4(Z1):1-2.TAN Gang. Analysis of the effect on silicon wafer CMP velocity [J]. Microelectronic Technology,2007,4(Z1):1-2. [24] LI B, MEI T, CHU H, et al. Ultrasonic-assisted electrodeposition of Ni/diamond composite coatings and its structure and electrochemical properties [J]. Ultrasonics Sonochemistry,2021,73(28):105475. [25] 赵保会. 超高速磨削用CBN砂轮陶瓷结合剂的研究 [D]. 天津: 天津大学, 2012.ZHAO Baohui. Research of vitrified bond for ultra-high speed CBN grinding wheel [D]. Tianjin: Tianjin University, 2012. -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS