Analysis and optimization of traveling wave resonance of diamond circular saw blade

-

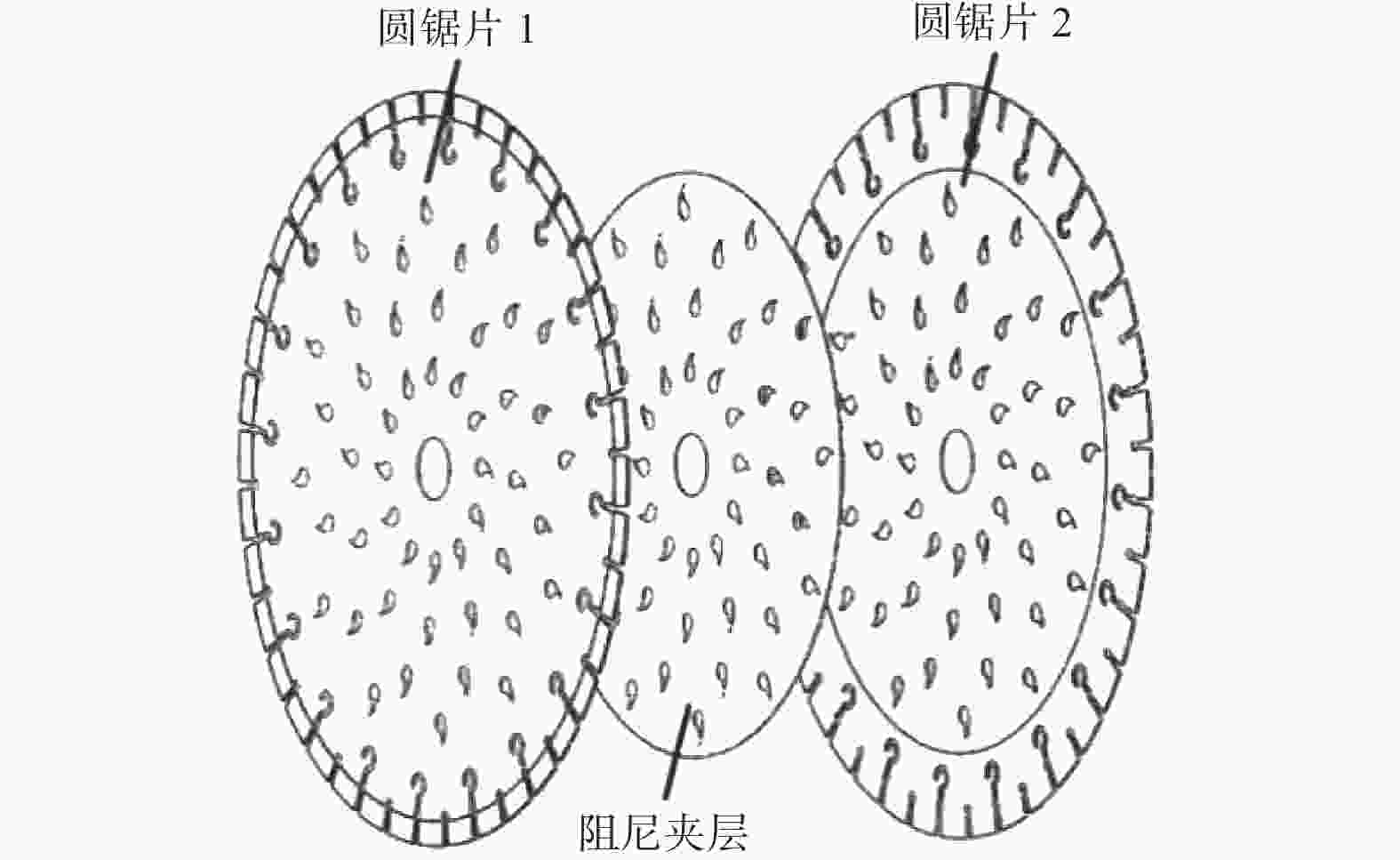

摘要: 针对金刚石圆锯片工作时出现的共振和噪声问题,利用Workbench软件对直径600 mm空转的圆锯片进行行波共振和静力分析,研究圆锯片基体中的开孔和夹层对其行波共振的影响。结果表明:圆锯片基体上合理开孔可以规避行波共振,其中开雨滴型孔的圆锯片减振效果最好,其δ最大值为4.36%,远大于未开孔与开圆形流线型孔的0.09%和0.91%。进一步对开雨滴型孔的圆锯片的夹层进行优化,其δ值为7.58%,达到夹层前的近2倍,更不容易引起行波共振。同时,优化后的圆锯片变形和应力值变大,但远小于其许用应力值,表明其强度和刚度满足使用要求,不会造成疲劳失效。Abstract: To solve the resonance and the noise problems of diamond circular saw blades during operation, the workbench software was used to analyze the traveling wave resonance and the static force of the idling circular saw blade with the diameter of 600 mm, and the effects of openings and interlayers in the circular saw blade matrix on its traveling wave resonance were studied. The results show that the reasonable openings in the matrix of circular saw blade can avoid traveling wave resonance, and the circular saw blade with raindrop holes has the best vibration reduction effect, the maximum value of δ is 4.36%, which is much larger than 0.09% and 0.91% of non-perforated and circular streamlined holes. The interlayer of circular saw blade with raindrop holes is further optimized, its δ value is 7.58%, which is nearly twice that before the interlayer, and it is not easy to cause traveling wave resonance. At the same time, the deformation and stress of the optimized circular saw blade become larger, but far less than its allowable stress value, indicating that its strength and stiffness meet the service requirements and will not cause fatigue failure.

-

Key words:

- diamond circular saw blade /

- modal analysis /

- traveling wave resonance /

- static analysis

-

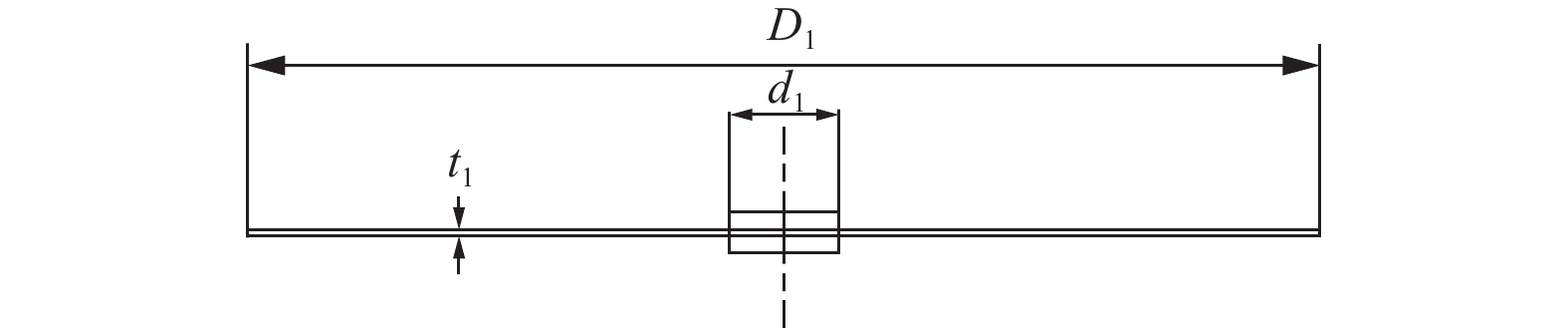

表 1 ϕ600 mm金刚石圆锯片基本参数

Table 1. Basic parameters of ϕ600 mm diamond circular saw blade

参数 取值 外径 D1 / mm 600 内径 d1 / mm 50 厚度 t1 / mm 2.8 齿数 Z / 个 40 弹性模量 E1 / Pa 2.1$ \times $1011 泊松比 ε1 0.30 密度 ρ1 / (kg·m−3) 7 800 表 2 ϕ600 mm基体开孔金刚石圆锯片固有频率表

Table 2. Natural frequency table of ϕ600 mm matrix slotted diamond circular saw blade

阶数 固有频率 P / Hz 方案一 方案二 方案三 1 24.5 24.3 23.1 10 181.8 162.0 161.9 20 378.1 249.3 250.4 30 561.6 450.5 443.3 40 766.4 528.5 533.7 50 1 049.7 677.7 687.4 60 1 220.8 841.2 836.6 70 1 365.2 1 153.4 1 148.2 80 1 539.2 1 423.1 1 432.2 90 1 902.9 1 692.6 1 694.4 100 2 101.6 1 814.8 1 827.3 110 2 371.9 1 879.3 1 913.9 120 2 432.4 2 089.3 2 078.6 124 2 549.8 2 135.5 2135.4 130 2 720.8 2 267.7 2 294.0 140 3 061.3 2 402.3 2 471.4 150 3 433.9 2 606.5 2 625.8 153 3 522.7 2 679.6 2 655.3 154 3 533.2 2 739.8 2 714.3 157 3 639.5 2 772.1 2745.7 160 3 733.8 2 964.4 2 913.5 170 3 946.2 3 284.0 3 288.6 180 4 148.2 3 589.1 3 578.3 190 4 336.0 3 780.6 3 737.7 200 4 547.0 3 977.7 3 959.3 表 3 金刚石圆锯片的行波振动分析数据表

Table 3. Data sheet of traveling wave vibration analysis of diamond circular saw blade

方案 数据 $ {P}_{{\rm{f}}} $ / Hz $ {P}_{{\rm{b}}} $ / Hz p / Hz Δ/ Hz δ / % 一 2 683.0 2 661.7 2 664.0 2.3 0.09 二 2 639.8 2 605.6 2 664.0 24.2 0.91 三 3 021.6 2 547.8 2 664.0 116.2 4.36 表 4 阻尼夹层基本参数

Table 4. Basic parameters of damping interlayer

参数 取值 外径 D2 / mm 450 内径 d2 / mm 50 厚度 t2 / mm 1.0 弹性模量 E2 / Pa 7.8×106 泊松比 ε2 0.47 密度 ρ2 / (kg·m−3) 1 300 表 5 方案四中100阶的固有频率

Table 5. 100 order natural frequencies in method 4

阶数 固有频率 P / Hz 阶数 固有频率 P / Hz 1 13.8 80 724.6 5 32.2 85 741.6 10 106.5 90 829.2 15 154.0 95 868.3 20 201.1 100 982.7 25 242.9 105 1 073.9 30 279.3 110 1 094.0 35 320.9 115 1 133.5 40 391.3 120 1 241.2 45 418.1 125 1 284.6 50 460.7 130 1 392.4 55 474.2 135 1 464.2 60 530.9 140 1 525.9 65 605.0 145 1 558.8 70 685.8 150 1 608.8 75 703.1 表 6 方案四的行波振动分析数据

Table 6. Traveling wave vibration analysis data of fourth scheme

项目 取值 Pf / Hz 1 184.8 Pb / Hz 1 231.1 p / Hz 1 332.0 Δ / Hz 100.9 δ / % 7.58 -

[1] 田永军, 孙爽, 张翔宇, 等. 金刚石圆锯片振动与噪声机理及其减振降噪技术研究综述 [J]. 机械设计,2020,37(3):1-13.TIAN Yongjun, SUN Shuang, ZHANG Xiangyu, et al. Review of the research on the vibration and noise mechanism of diamond circular saw blades and the vibration-and-noise reduction technology [J]. Journal of Machine Design,2020,37(3):1-13. [2] 范勇, 李波, 徐凯, 等. 金刚石圆锯片结构与其模态频率的关联性研究 [J]. 机械设计与制造,2019(4):13-16. doi: 10.3969/j.issn.1001-3997.2019.04.004FAN Yong, LI Bo, XU Kai, et al. Study on the correlation between structure and modal frequency of diamond circular saw blades [J]. Machinery Design & Manufacture,2019(4):13-16. doi: 10.3969/j.issn.1001-3997.2019.04.004 [3] FENG W, ZHANG J S, ZHOU H R, et al. Investigation on the vibration characteristics of circular saw blade with different slots [J]. Journal of Physics Conference Series, 2020,1633:012006. [4] 田永军, 徐国胜, 张翔宇, 等. 多约束条件下金刚石圆锯片结构优化研究 [J]. 振动与冲击,2020,39(7):260-267.TIAN Yongjun, XU Guosheng, ZHANG Xiangyu, et al. Research on structural optimization of diamond circular saw blade under multi-constraints conditions [J]. Journal of Vibration and Shock,2020,39(7):260-267. [5] 于家伟. 大直径金刚石圆锯片降噪孔参数优化研究 [D]. 济南: 山东大学, 2017.YU Jiawei. Study on the parameter optimization of noise-reduction holes of the large diamond saw blades [D]. Jinan: Shandong University, 2017. [6] 早坂谦司, 山巅直树, 野中哲也, 等. 金刚石圆锯片振动与噪声的研究(第一报)−齿数、齿缝和固有频率对吹笛声的影响 [J]. 精密工学会志,1993,59(12):2032-2036.HAYASAKA Kenji, TOUGE Naoki, NONOSHITA Tetsuya, et al. Investigation on generation of vibration and noise of diamond circular saw blades (1nd report)—Effect of number of segments, slit, and natural vibration on whistling noise [J]. Journal of Seiko Society,1993,59(12):2032-2036. [7] 早坂谦司, 山巅直树, 野中哲也, 等. 金刚石圆锯片振动与噪声的研究(第二报)−观察振动模态和空气流动 [J]. 精密工学会志,1998,64(3):399-402.HAYASAKA Kenji, TOUGE Naoki, NONOSHITA Tetsuya, et al. Investigation on generation of vibration and noise of diamond circular saw blades (2nd report)—Observation of a mode of vibration and the air flow [J]. Journal of Seiko Society,1998,64(3):399-402. [8] 王婷. 夹层阻尼圆锯片减振降噪研究 [D]. 天津: 河北工业大学, 2013.WANG Ting. Research on vibration and noise reduction of damping sandwich circular saw [D]. Tianjin: Hebei University of Technology. 2013. [9] 罗瑜, 罗艳蕾, 管传宝, 等. 行星减速装置接触疲劳寿命的有限元分析 [J]. 机械传动,2017,41(4):106-109.LUO Yu, LUO Yanlei, GUAN Chuanbao, et al. Finite element analysis of contact fatigue life of planetary reducer [J]. Journal of Mechanical Transmission,2017,41(4):106-109. [10] LINH V T, ZANG Y. Calculation of the stiffness in the roll tensioning of the circular saw blade [J]. MATEC Web of Conferences,2016,51:01007. doi: 10.1051/matecconf/20165101007 [11] 房怀英, 李远, 徐西鹏. 轴向力对圆锯片轴向变形的影响研究 [J]. 中国机械工程,2011,22(8):966-970.FANG Huaiying, LI Yuan, XU Xipeng. Influences of axial force on axial deformation of circular saws [J]. China Mechanical Engineering,2011,22(8):966-970. -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS