Influence of grinding lubrication methods on surface integrity of nickel-based single crystal superalloy

-

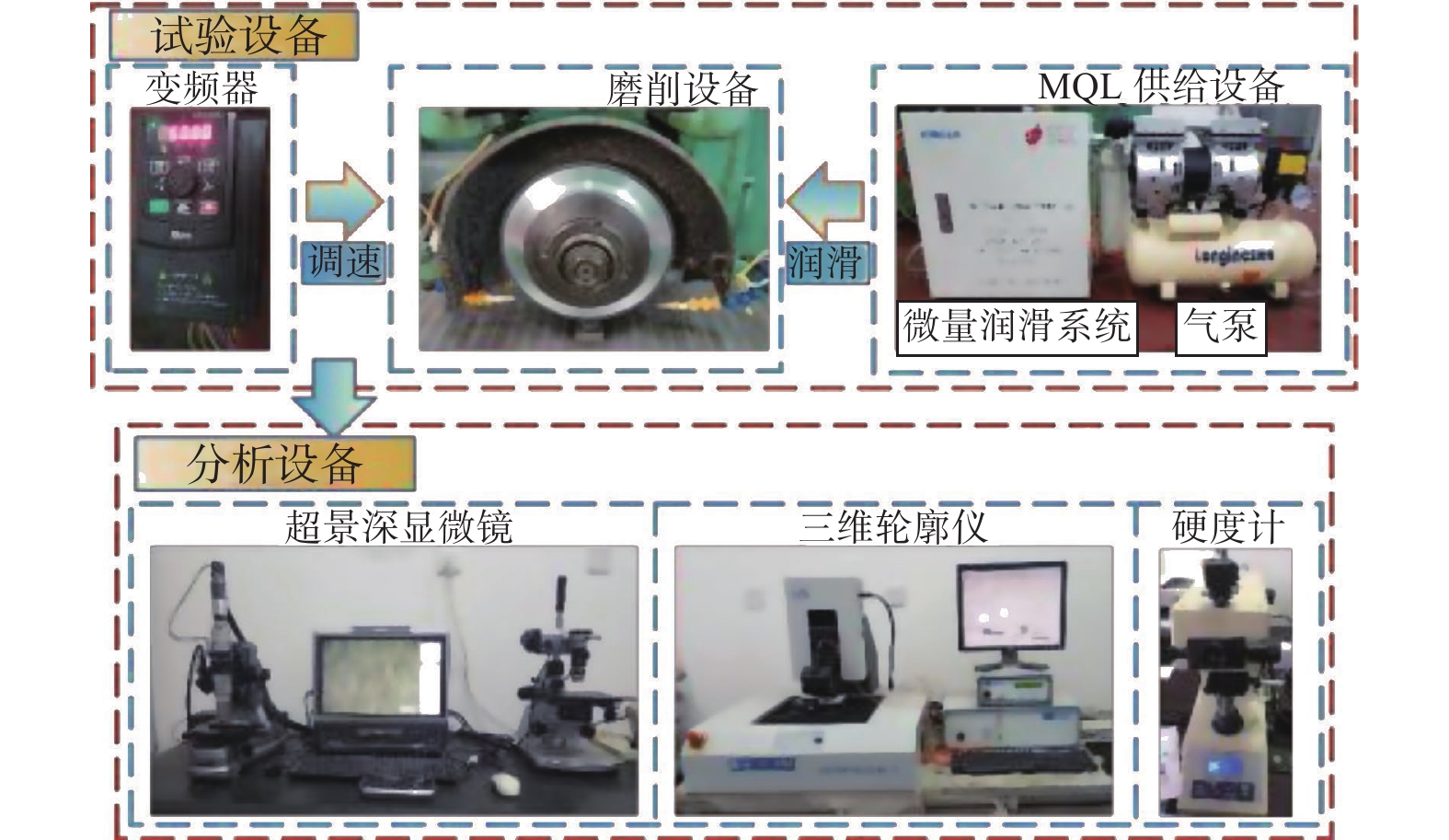

摘要: 为提高镍基单晶高温合金DD5的磨削表面质量,采用单因素试验探究3种磨削加工方法(干磨削、传统浇注式、微量润滑(minimum quantity lubrication, MQL))对其表面完整性的影响。结果表明:在不同冷却条件下,DD5磨削表面粗糙度从低到高依次为MQL、传统浇注式、干磨削方式下的。当砂轮线速度较小时,磨削表面质量较差,存在较深划痕和沟槽;当砂轮线速度较大时,磨削表面质量较好,磨痕较小,且分布均匀。在距磨削表面为5~15 μm时,DD5亚表面显微硬度随着深度的增加而急剧下降;在距磨削表面为20~150 μm时,DD5亚表面显微硬度趋于平衡,其在540 HV附近波动。Abstract: To improve the grinding surface quality of nickel-based single crystal superalloy DD5, the influence of three grinding methods (dry, conventional flood, minimal quantity lubrication) on their surface integrity was investigated using single factor experiment. The results show that under different cooling conditions, the grinding surface roughness of nickel-based single crystal superalloy DD5 is MQL, conventional flood and dry grinding from low to high. When the linear speed of the grinding wheel is small, the grinding surface quality is poor, and there are deep scratches and grooves; when the linear speed of the grinding wheel is large, the grinding surface quality is good, the grinding marks are small and evenly distributed. When the depth from the grinding surface is 5~15 μm, the subsurface microhardness of DD5 decreases sharply with the increase of depth. When the depth from the grinding surface is 20~150 μm, the subsurface microhardness of DD5 tends to balance and fluctuates around 540 HV.

-

表 1 磨削表面粗糙度单因素试验结果

Table 1. Single factor experiment results of grinding surface roughness

条件 砂轮线

速度

vs / (m·s−1)磨削

深度

ap / µm进给速度

vf / (m·min−1)表面粗糙度Ra / μm 干磨削 传统

浇注式MQL 1 15 60 0.6 0.983 0.843 0.775 2 20 60 0.6 0.927 0.815 0.734 3 25 20 0.6 0.826 0.685 0.627 4 25 40 0.6 0.865 0.693 0.632 5 25 60 0.6 0.896 0.767 0.658 6 25 80 0.6 0.923 0.796 0.713 7 25 100 0.6 0.955 0.835 0.754 8 25 60 0.2 0.853 0.746 0.629 9 25 60 0.4 0.879 0.757 0.637 10 25 60 0.8 0.926 0.778 0.673 11 25 60 1.0 0.986 0.794 0.688 12 30 60 0.6 0.861 0.742 0.626 13 35 60 0.6 0.809 0.703 0.614 -

[1] 周云光. 镍基单晶高温合金微磨削工艺理论与关键技术研究 [D]. 沈阳: 东北大学, 2017.ZHOU Yunguang. Research on micro-grinding technology theory and key technology of nickel-based single crystal superalloy [D]. Shenyang: Northeastern University, 2017. [2] 刘爽, 李敏, 丁文锋, 等. 刚玉砂轮缓进深切磨削K444镍基高温合金研究 [J]. 金刚石与磨料磨具工程,2021,41(4):72-81.LIU Shuang, LI Min, DING Wenfeng, et al. Research on slowly advanced deep grinding of K444 nickel base superalloy [J]. Diamond & Abrasives Engineering,2021,41(4):72-81. [3] 巩亚东, 张伟健, 蔡明, 等. 镍基单晶高温合金磨削变质层工艺试验研究 [J]. 东北大学学报(自然科学版),2020,41(6):846-851. doi: 10.12068/j.issn.1005-3026.2020.06.015GONG Yadong, ZHANG Weijian, CAI Ming, et al. Experimental study on grinding modification layer of nickel-based single crystal superalloy [J]. Journal of Northeast University (Natural Science Edition),2020,41(6):846-851. doi: 10.12068/j.issn.1005-3026.2020.06.015 [4] 张帅奇, 杨忠学, 张长春, 等. DD5镍基单晶高温合金缓进磨削力和温度实验研究 [J]. 航空工程进展,2021,12(4):80-89.ZHANG Shuaiqi, YANG Zhongxue, ZHANG Changchun, et al. Experimental study on creep grinding force and temperature of DD5 nickel-based single crystal superalloy [J]. Progress in Aeronautical Engineering,2021,12(4):80-89. [5] 蔡明, 巩亚东, 屈硕硕, 等. 镍基单晶高温合金磨削表面质量及亚表面微观组织试验 [J]. 东北大学学报(自然科学版),2019,40(3):386-391. doi: 10.12068/j.issn.1005-3026.2019.03.016CAI Ming, GONG Yadong, QU Shuoshuo, et al. Experiment of grinding surface quality and subsurface microstructure for nickel-based single crystal superalloy [J]. Journal of Northeast University (Natural Science Edition),2019,40(3):386-391. doi: 10.12068/j.issn.1005-3026.2019.03.016 [6] LI Q, GONG Y, CAI M, et al. Research on surface integrity in milling Inconel718 superalloy [J]. The International Journal of Advanced Manufacturing Technology,2017,92(1):1449-1463. [7] DA SILVA L R, BIANCHI E C, FUSSE R Y, et al. Analysis of surface integrity for minimum quantity lubricant—MQL in grinding [J]. International Journal of Machine Tools and Manufacture,2007,47(2):412-418. doi: 10.1016/j.ijmachtools.2006.03.015 [8] SADEGHI M, HADDAD M, TAWAKOLI T, et al. Minimal quantity lubrication-MQL in grinding of Ti–6Al–4V titanium alloy [J]. The International Journal of Advanced Manufacturing Technology,2009,44(5):487-500. [9] YAZID M, CHEHARON C, GHANI J, et al. Surface integrity of Inconel 718 when finish turning with PVD coated carbide tool under MQL [J]. Procedia Engineering,2011,19:396-401. doi: 10.1016/j.proeng.2011.11.131 [10] 贺爱东, 叶邦彦, 覃孟扬, 等. 微量润滑对切削加工残余应力的影响 [J]. 湖南大学学报(自然科学版),2015,42(10):48-53.HE Aidong, YE Bangyan, QIN Mengyang, et al. Effect of micro lubrication on cutting residual stress [J]. Journal of Hunan University (Natural Science Edition),2015,42(10):48-53. -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS