Effect of iron-base amorphous powder on diamond tool matrix

-

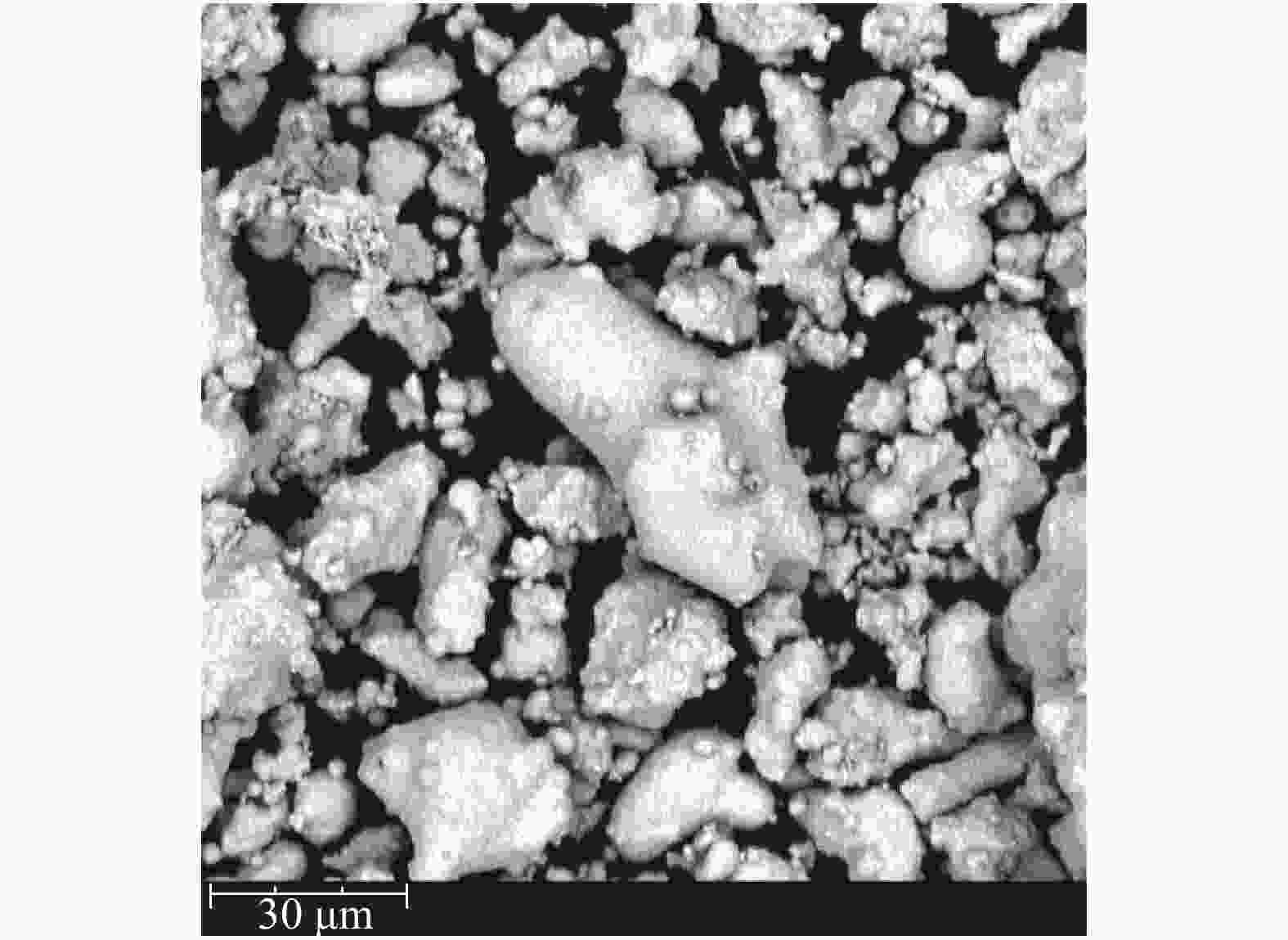

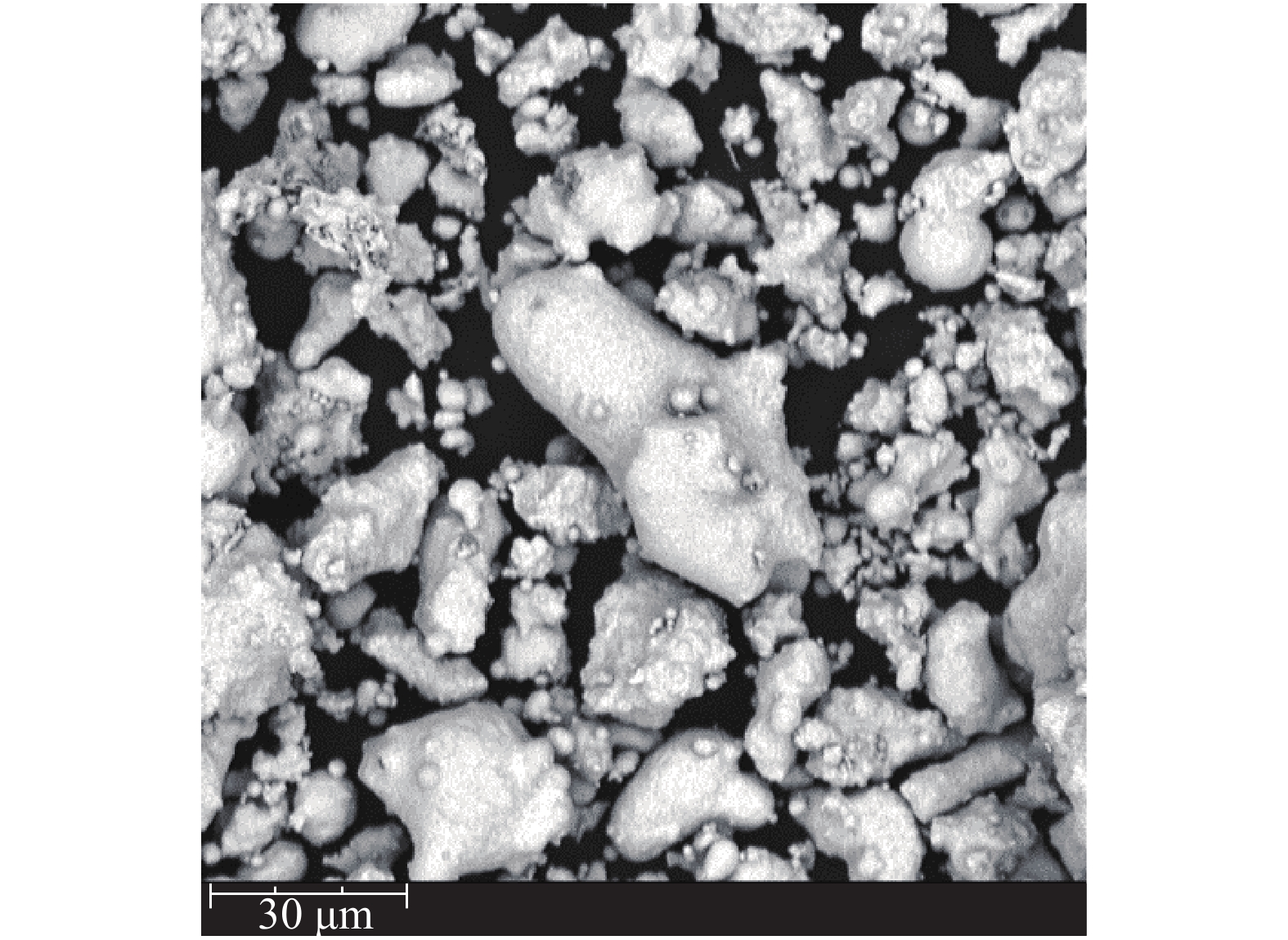

摘要: 将不同质量分数(分别为0,5%,10%和15%)的铁基非晶粉末加入铁基预合金粉末胎体中,通过热压烧结制成胎体试样后,测试其洛氏硬度、抗弯强度及磨损率。当不添加非晶粉末时,普通胎体的洛氏硬度、抗弯强度和磨损率分别为104.6 HRB, 610 MPa和3.3;加入10%的非晶粉末后,其洛氏硬度和抗弯强度分别提高至107.7 HRB和965 MPa,比原胎体分别提高了3.0%和58.2%,磨损率降低至0.9,降低了72.7%;加入15%的非晶粉末后,其洛氏硬度和抗弯强度分别提高至110.0 HRB和790 MPa,分别提高了5.2%和29.5%,磨损率降低至0.6,降低了81.8%。因而铁基非晶粉末的加入可以显著提高胎体试样的机械性能和耐磨性。此外,铁基非晶粉末的DSC及XRD测试发现,在500~700 ℃时,铁基非晶粉末会产生晶体化相变,NiSi相中融入了B元素转化成NiSiB相,CrFe相中融入了Si元素形成SiCrFe相,都起到改善胎体结构、提高胎体性能的目的。Abstract: The Fe-based amorphous powders with different mass fractions of 0, 5%, 10% and 15% were added to the matrix of Fe-based prealloyed powder. After the matrix sample was made by hot pressing sintering, the Rockwell hardness, the flexural strength and the wear rate were tested. For the sample without powder, its Rockwell hardness, flexural strength and wear rate are 104.6 HRB, 610 MPa and 3.3 respectively. For the sample adding 10% amorphous powder, its Rockwell hardness and flexural strength increase to 107.7 HRB and 965 MPa, which are 3.0% and 58.2% higher than the corresponding values of the original matrix respectively. The wear rate decreases to 0.9, which is 72.7% lower than the corresponding value of the original matrix. For the sample adding 15% amorphous powder, its Rockwell hardness and flexural strength increase to 110.0 HRB and 790 MPa, which are 5.2% and 29.5% higher than the corresponding values of the original matrix respectively. The wear rate decreases to 0.6, which is 81.8% lower than the corresponding value of the original matrix. Therefore, the addition of Fe-based amorphous powder can significantly improve the mechanical properties and the wear resistance of matrix samples. In addition, the DSC and the XRD tests of Fe-based amorphous powder show that at 500~700 ℃, the Fe-based amorphous powder will produce the process of crystalline phase transformation. The B element is integrated into NiSi phase to convert into NiSiB phase, and the Si element is integrated into CrFe phase to form SiCrFe phase, which can improve the matrix structure and properties.

-

Key words:

- Fe-base amorphous powder /

- Fe-based pre-alloyed powder /

- matrix /

- mechanical property /

- NiSi phase /

- CrFe phase

-

表 1 试验粉末

Table 1. Powder in experiment

粉末 基本粒径

d / μm元素构成 理论密度

ρ / (g·cm−3)铁基预合金粉末 74 Fe,Ni,Cu,Sn 8.03 铁基非晶粉末 74 Fe,W,Cr,Ni,Si,B,Mo 7.85 表 2 热压烧结参数

Table 2. Parameters of hot pressing sintering

烧结工艺 参数或取值 烧结方式 电阻炉加热 最高温度 tmax / ℃ 800 最高压力 pmax / MPa 17.25 保温时间 t1 / min 4 冷却方式 空冷 -

[1] BAI R, ZHANG S H, HAN Y, et al. Effect of CL192 pre-alloyed powder on matrix properties of impregnated diamond bit [J]. Diamond & Related Materials, 2020, 107: 107878. [2] 轩庆庆. CuSnTi活性钎料组织性能分析及非晶态钎料钎焊金刚石研究 [D]. 郑州: 机械科学研究总院郑州机械研究所, 2017.XUAN Qingqing. Analysis of microstructure and properties of CuSnTi active filler metal and study on brazing diamond with amorphous filler metal [D]. Zhengzhou: Zhengzhou Research Institute of Mechanical Engineering, China Academy of Machinery Science and Technology, 2017. [3] SHI J, NI B, ZHANG J, et al. Effect of Ni addition on catalytic performance of Fe87Si5B2P3Nb2Cu1 amorphous alloys for degrading methylene blue dyes [J]. Metals, 2019, 9(3): 341. [4] CHERKEZOVA-ZHELEVA Z, PANEVA D, PETKOVA V, et al. Reuse of Fe-based amorphous alloys containing CRM: Study on their temperature behavior [J]. Hyperfine Interactions, 2020, 241(1): 14. [5] 汪明文. Fe基非晶合金及复合粉末激光熔覆和性能研究 [D]. 福州: 福建农林大学, 2016.WANG Mingwen. Study the properties of Fe-based amorphous alloy and composite powder by laser cladding [D]. Fuzhou: Fujian Agriculture and Forestry University, 2016. [6] 李文博. 激光熔覆制备铁基非晶复合涂层的组织演变与性能调控研究 [D]. 福州: 福建农林大学, 2020.LI Wenbo. Study on microstructure evolution and property modulation of Fe-based amorphous composite coating synthesized by laser cladding [D]. Fuzhou: Fujian Agriculture and Forestry University, 2020. [7] 张琪. 铁基非晶显微组织的研究 [D]. 上海: 上海工程技术大学, 2020.ZHANG Qi. Study on Fe-based amorphous microstructure [D]. Shanghai: Shanghai University of Engineering Science, 2020. [8] 唐翠勇. 铁基非晶/纳米晶合金的制备、成形及性能研究 [D]. 广州: 华南理工大学, 2012.TANG Cuiyong. Study on the preparation, forming and property of Iron-based amorphous/nanocrystalline alloys [D]. Guangzhou: South China University of Technology, 2012. [9] 邹吉炜. 深冷和磁脉冲处理对Fe基非晶组织和磁性能的影响 [D]. 镇江: 江苏大学, 2019.ZOU Jiwei. Effect of cryogenic and magnetic pulse treatment on Fe-based amorphous microstructure and magnetic properties [D]. Zhenjiang: Jiangsu University, 2019. [10] 李子章. 金刚石定位排布的热压孕镶钻头研究 [D]. 成都: 成都理工大学, 2011.LI Zizhang. A study on hot-pressed impregnated diamond drilling bit in designed setting [D]. Chengdu: Chengdu University of Technology, 2011. [11] 田玉芹. Fe3Al基金属间化合物固溶强化和析出强化 [J]. 科技资讯,2008(12):2-3. doi: 10.3969/j.issn.1672-3791.2008.12.002TIAN Yuqin. Solid solution enhancement and precipitation enhancement of Fe3Al intergeneric compounds [J]. Science & Technology Information,2008(12):2-3. doi: 10.3969/j.issn.1672-3791.2008.12.002 -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS