Feasibility study on SiO2f/SiO2 composites processed by diamond tools

-

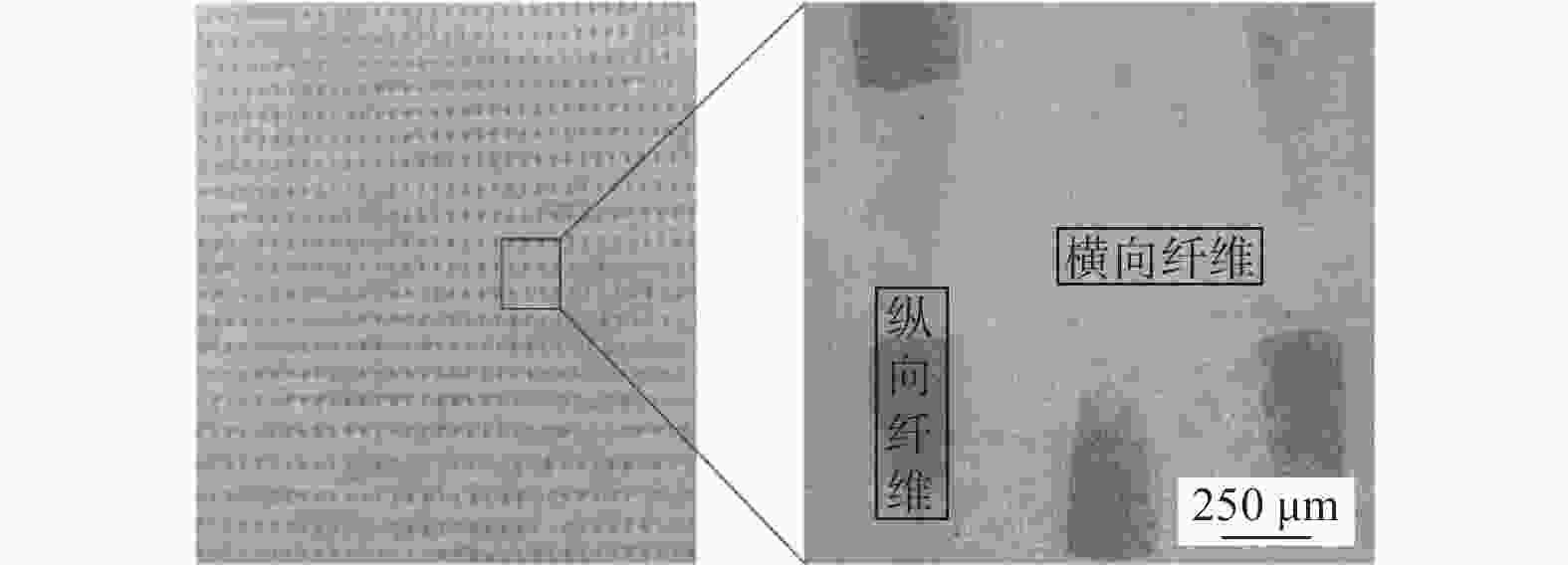

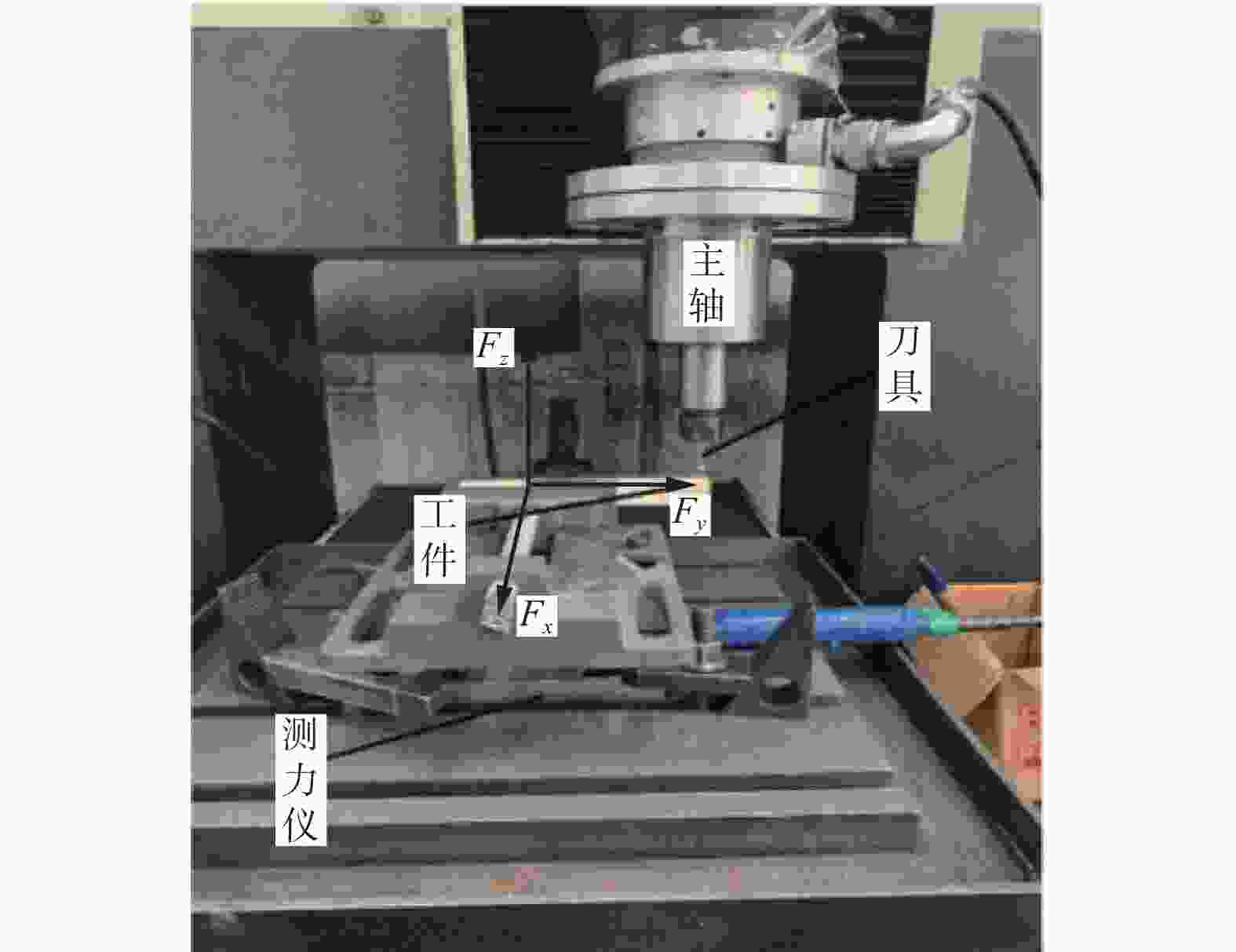

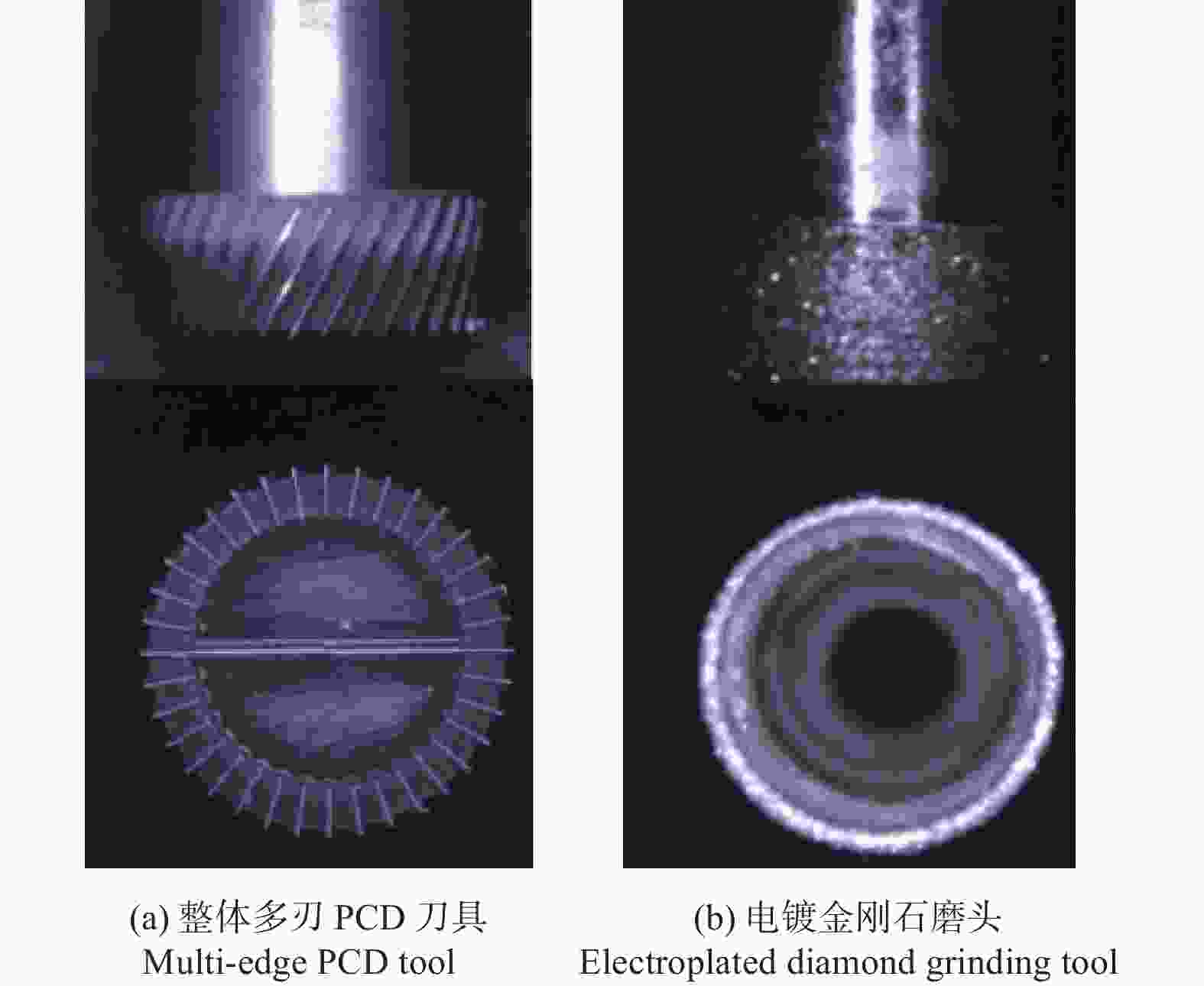

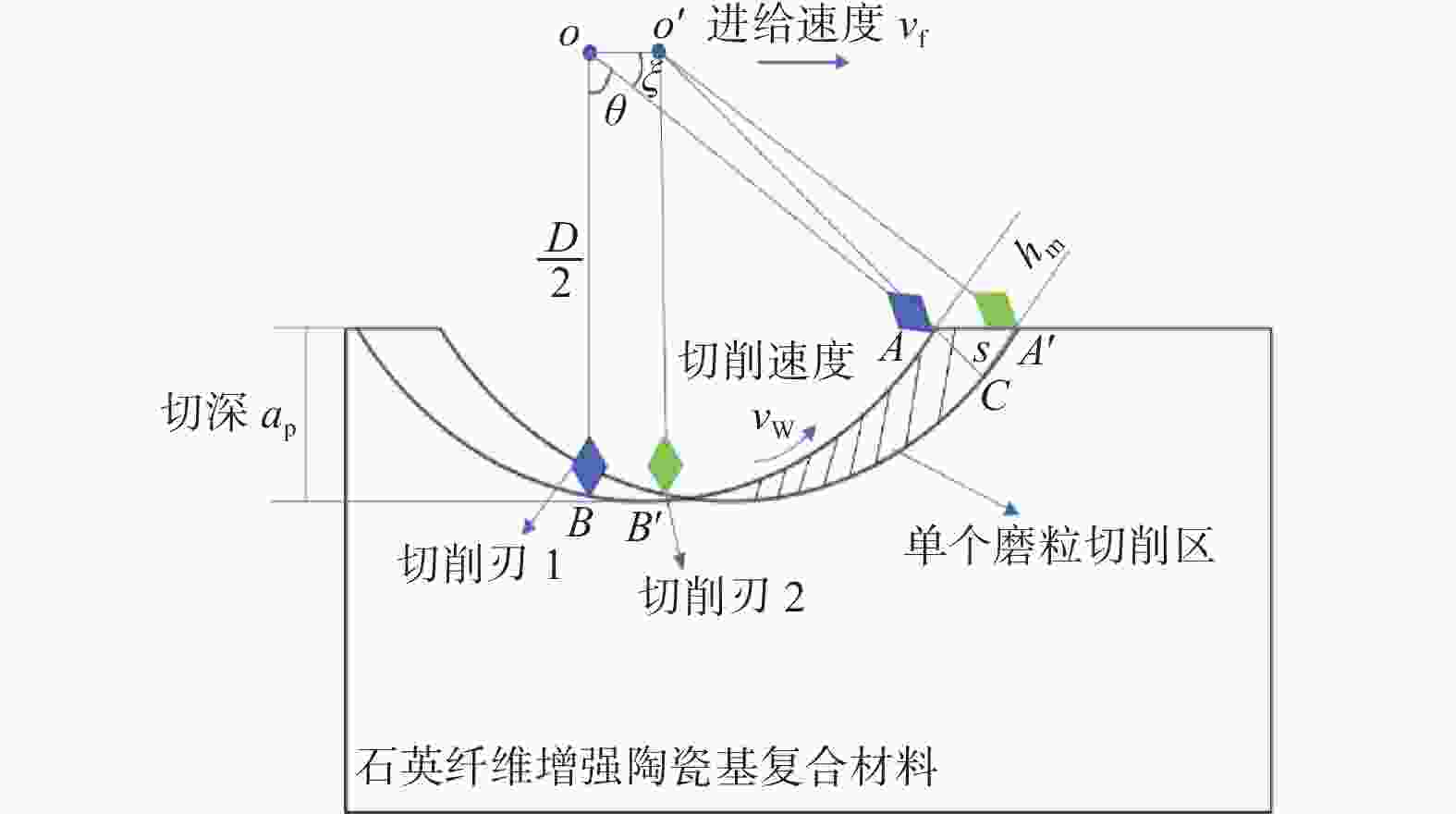

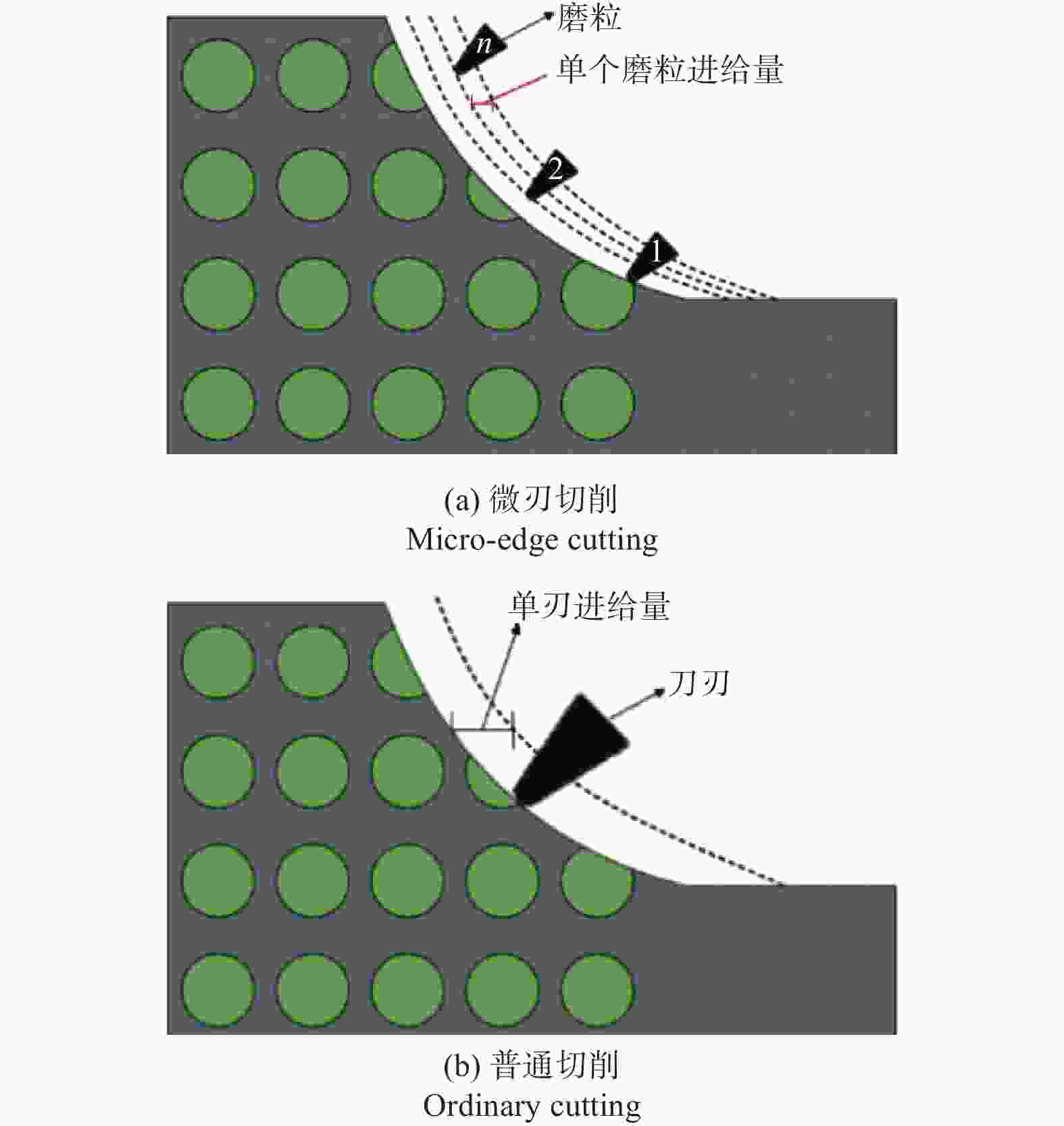

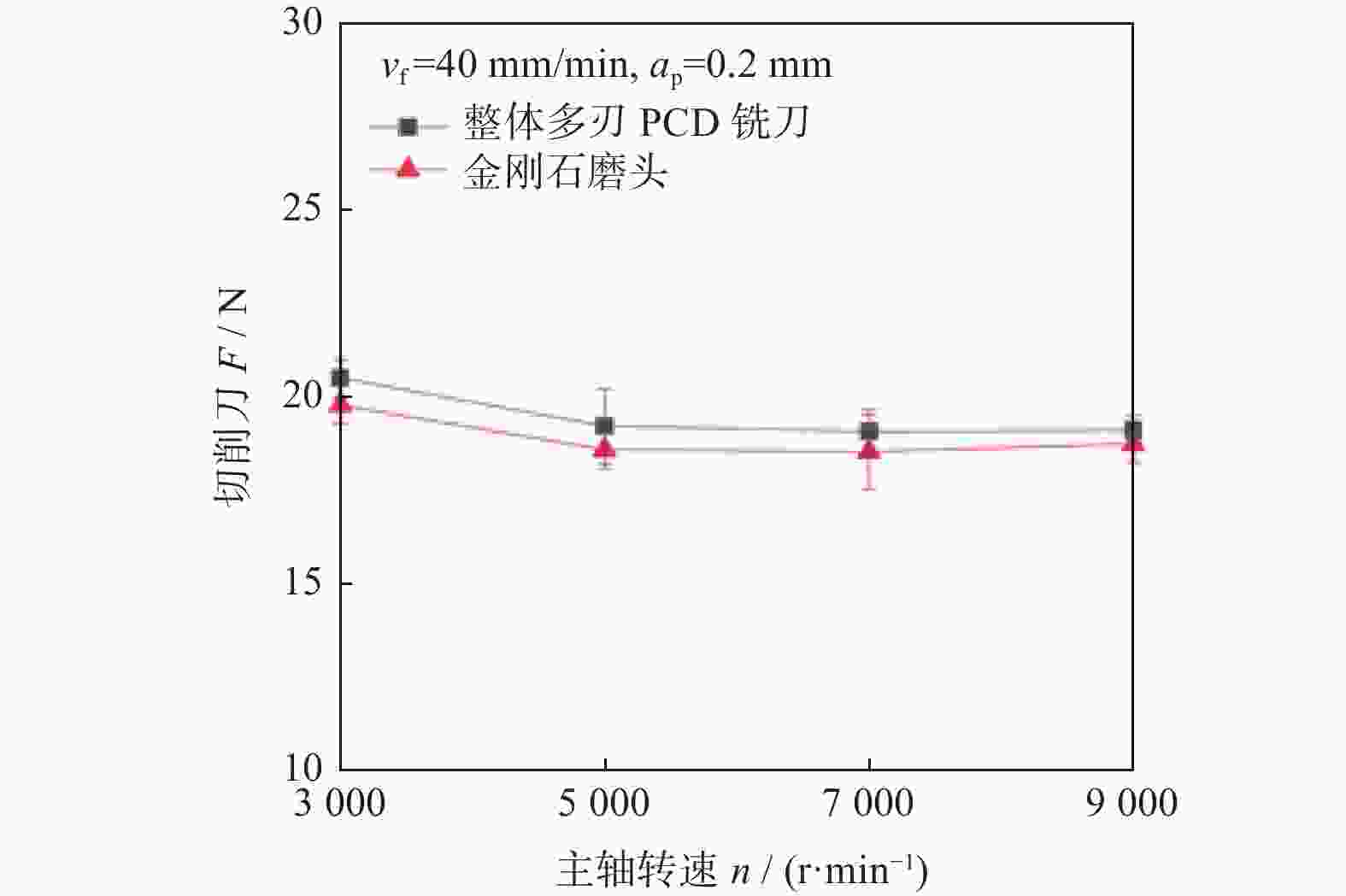

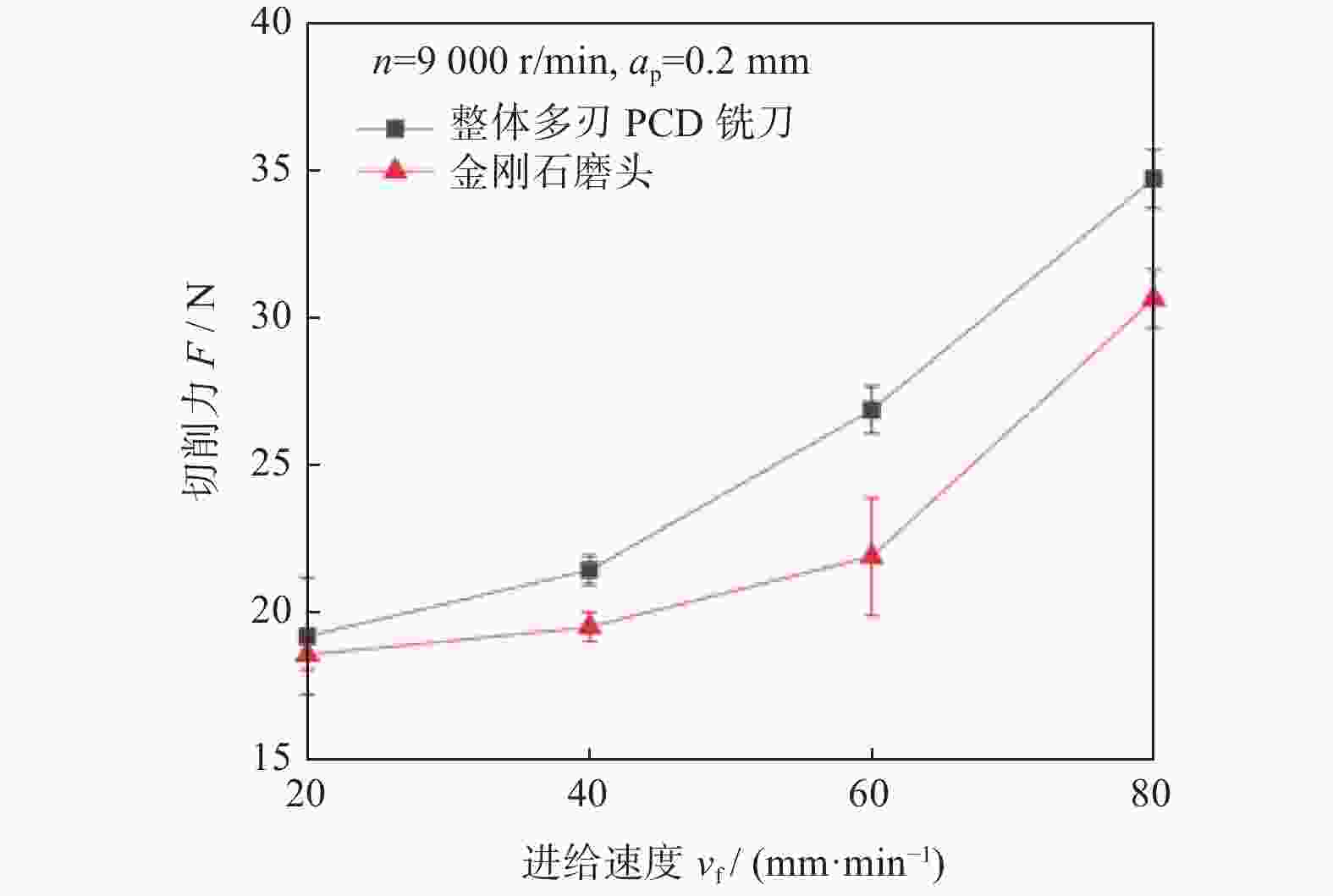

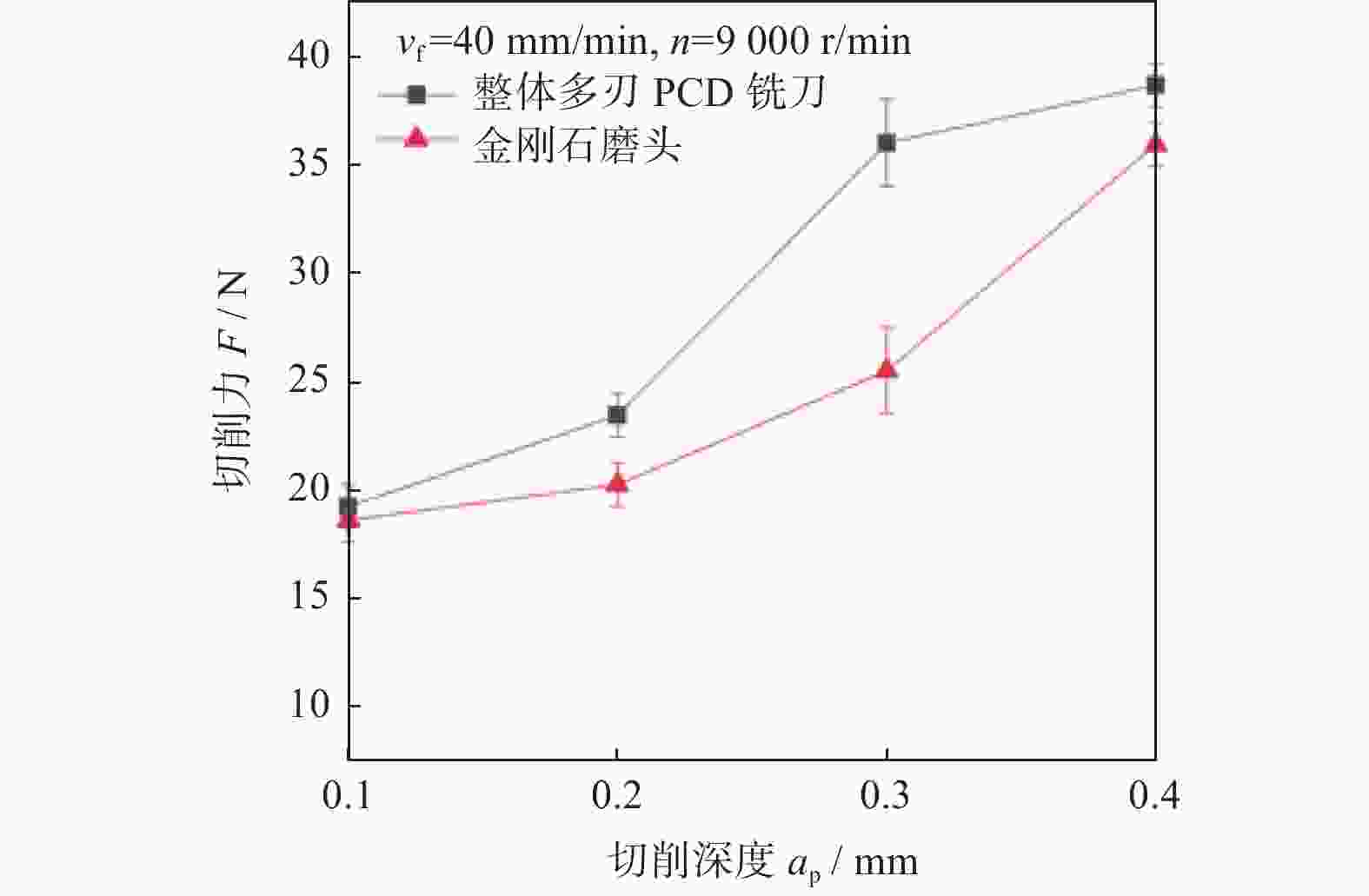

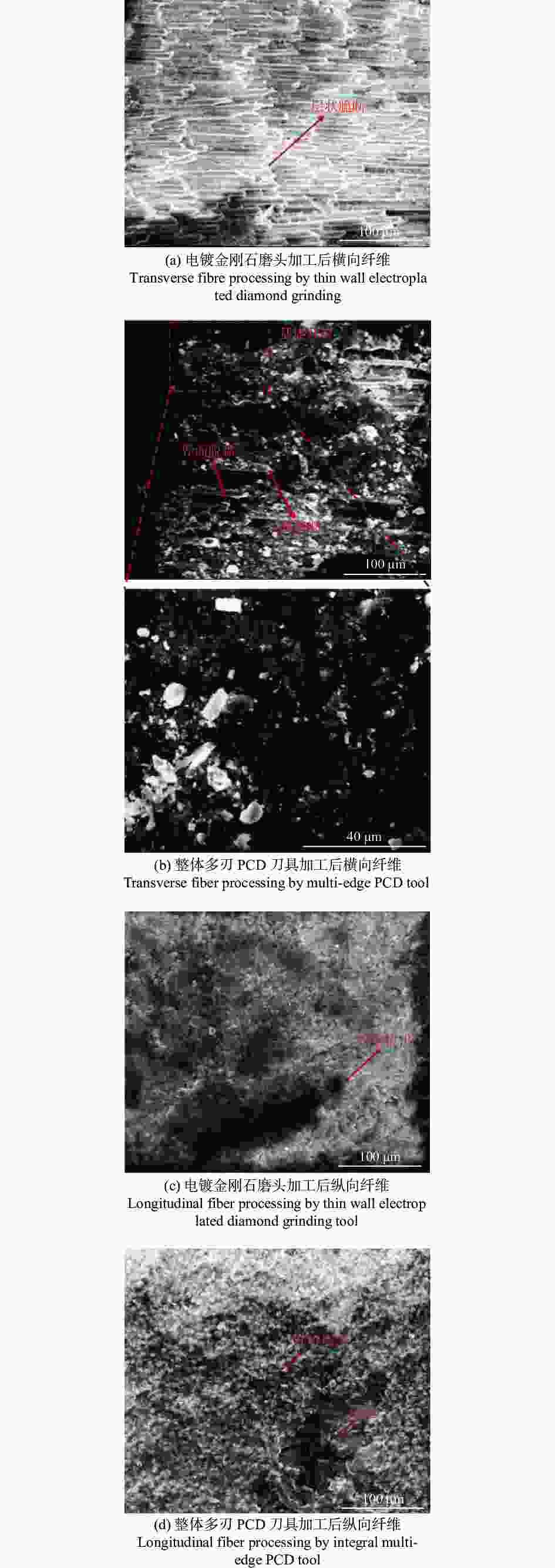

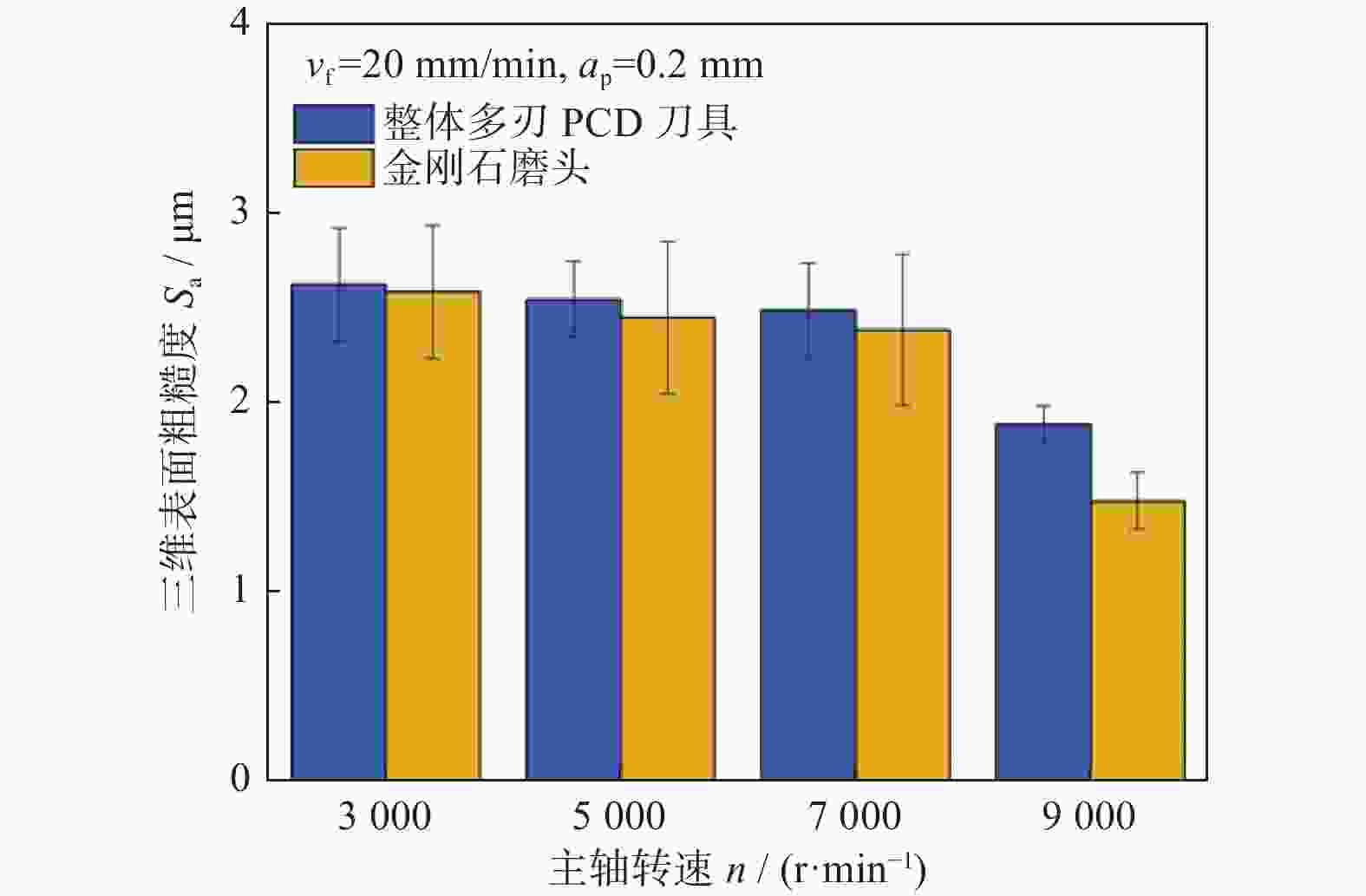

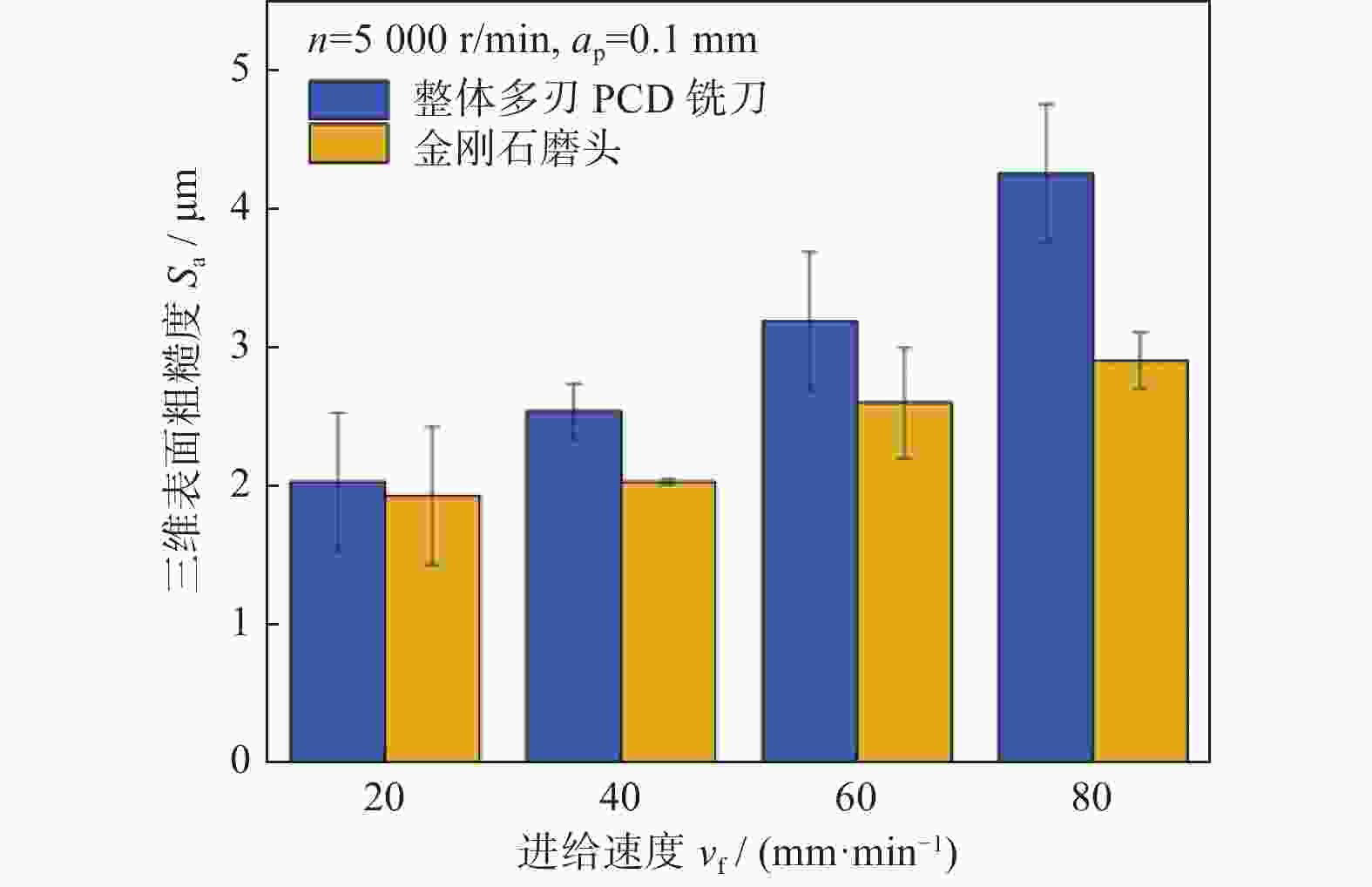

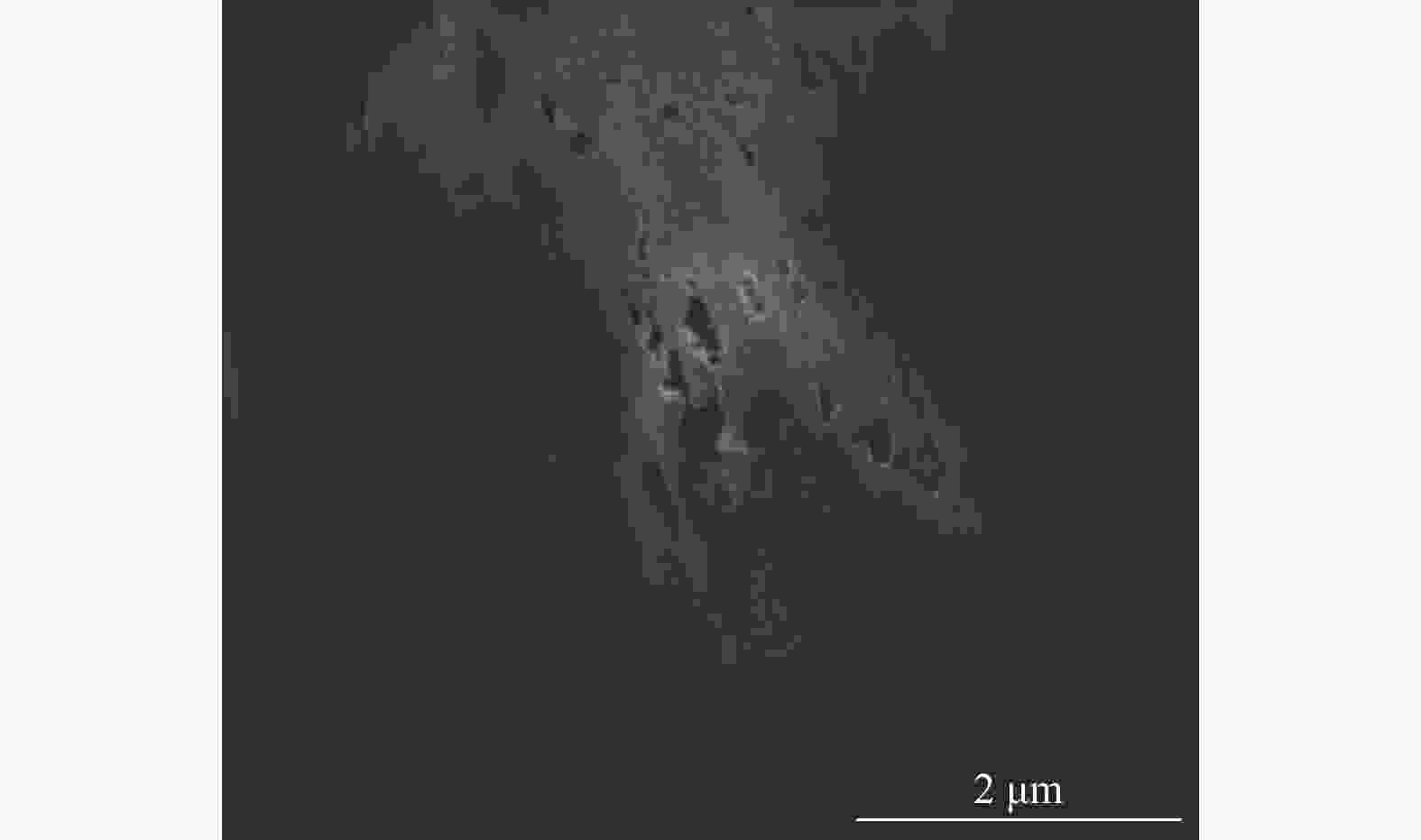

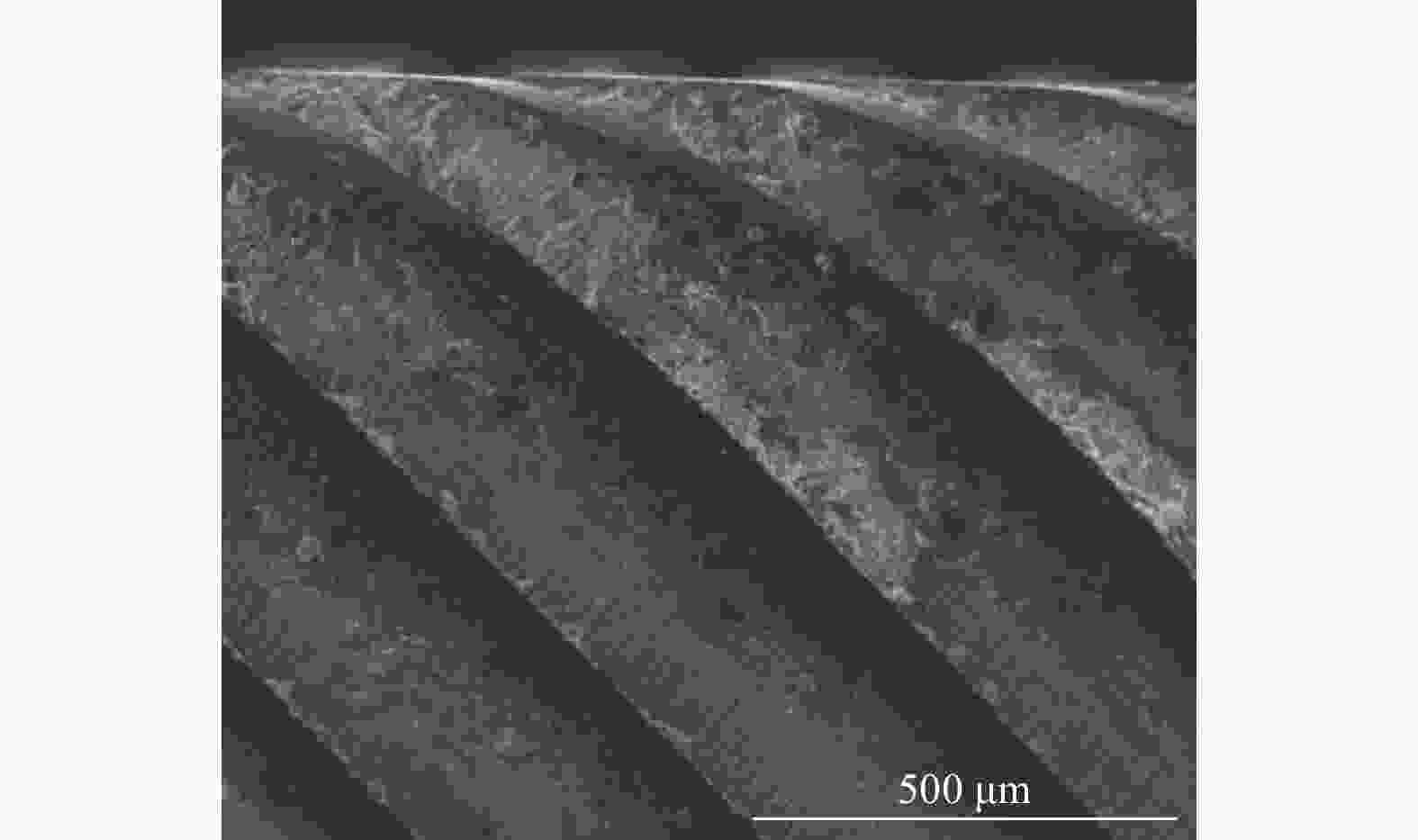

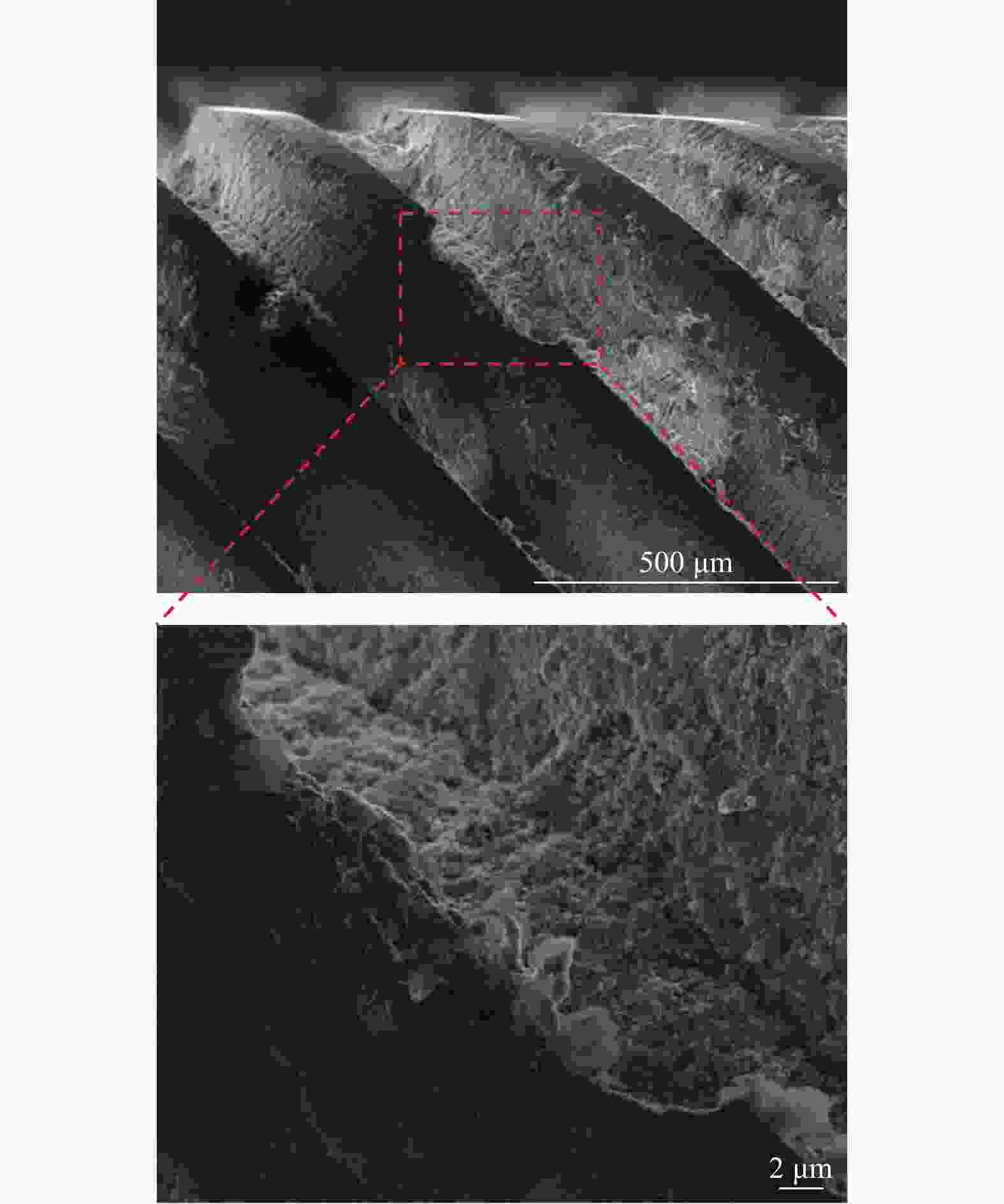

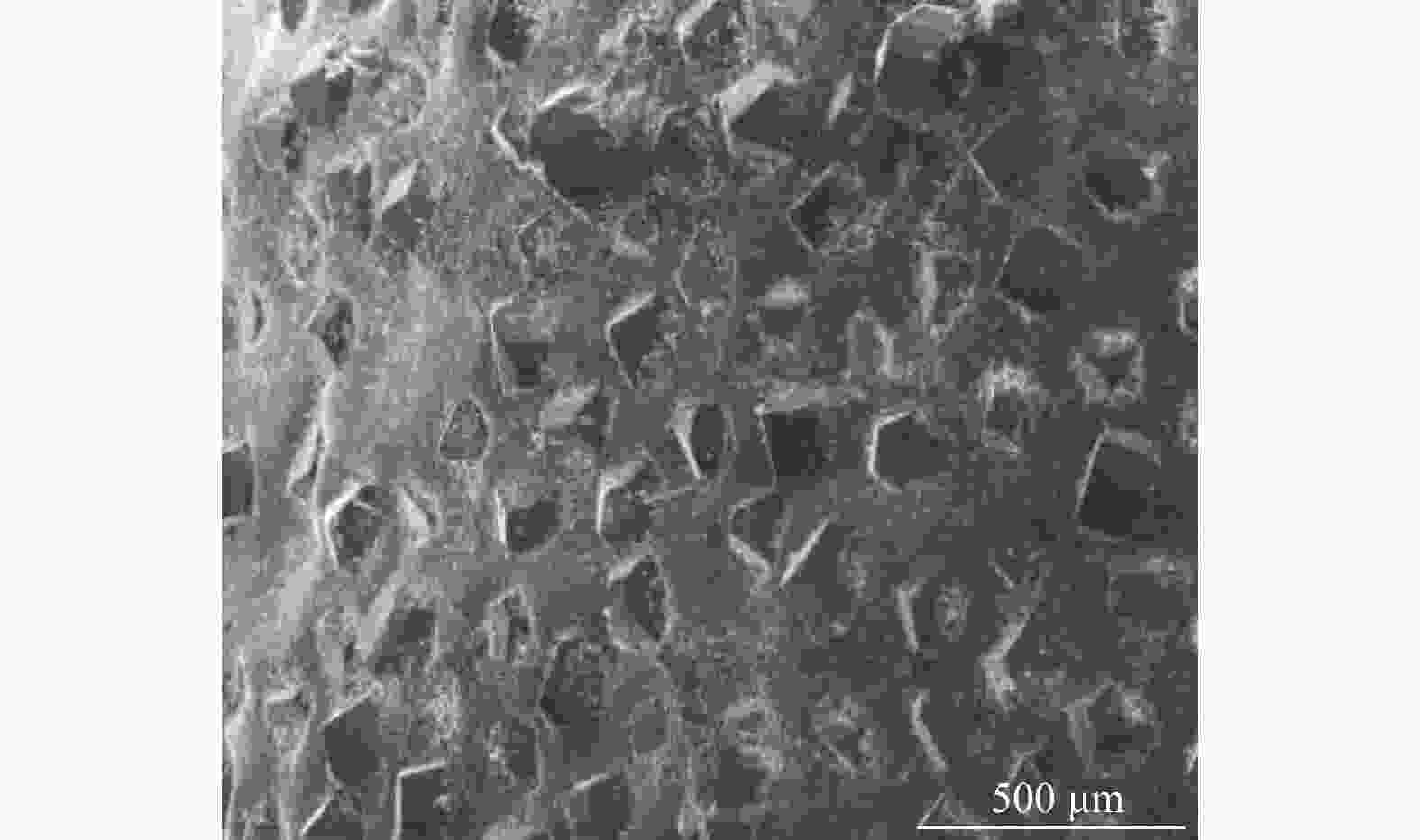

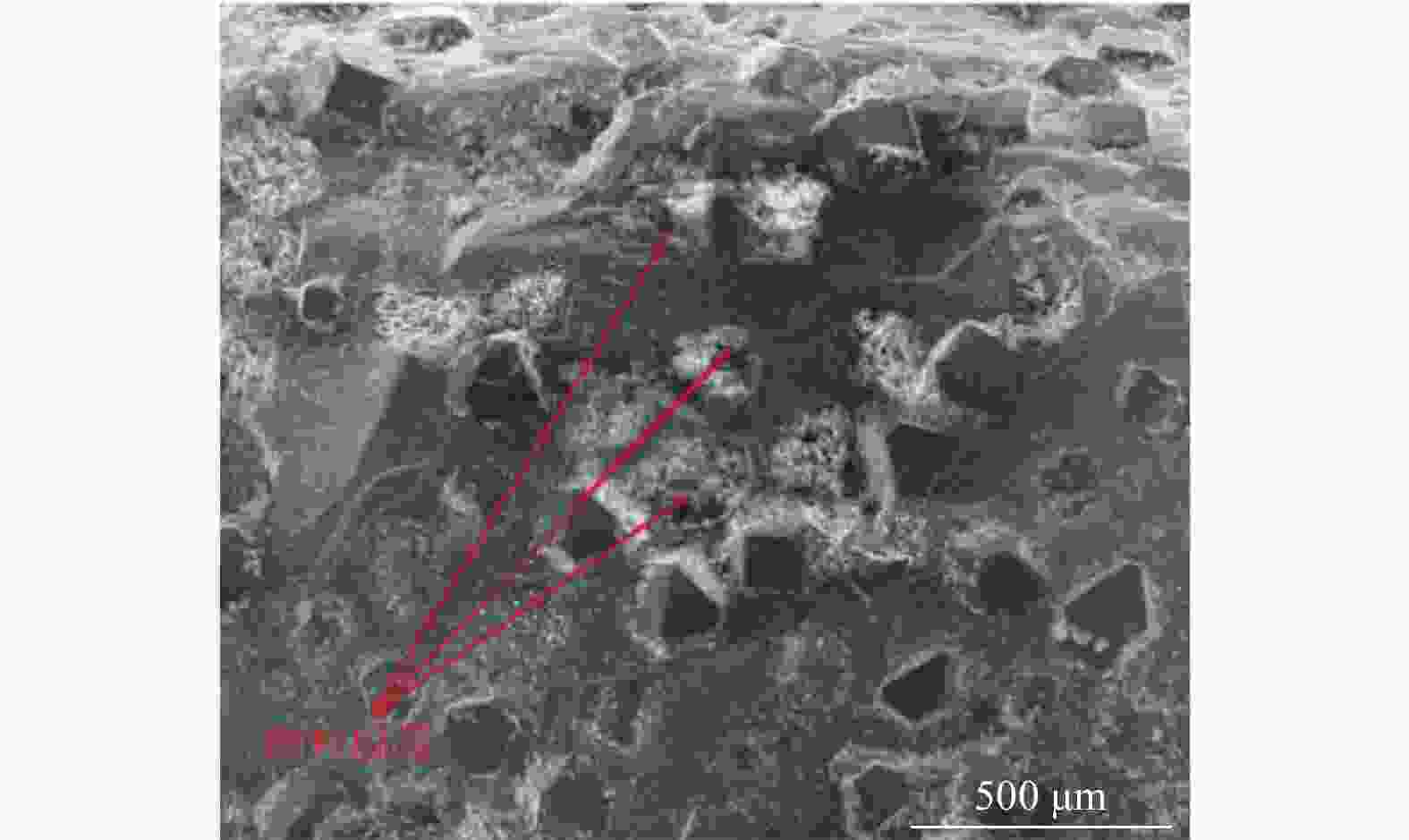

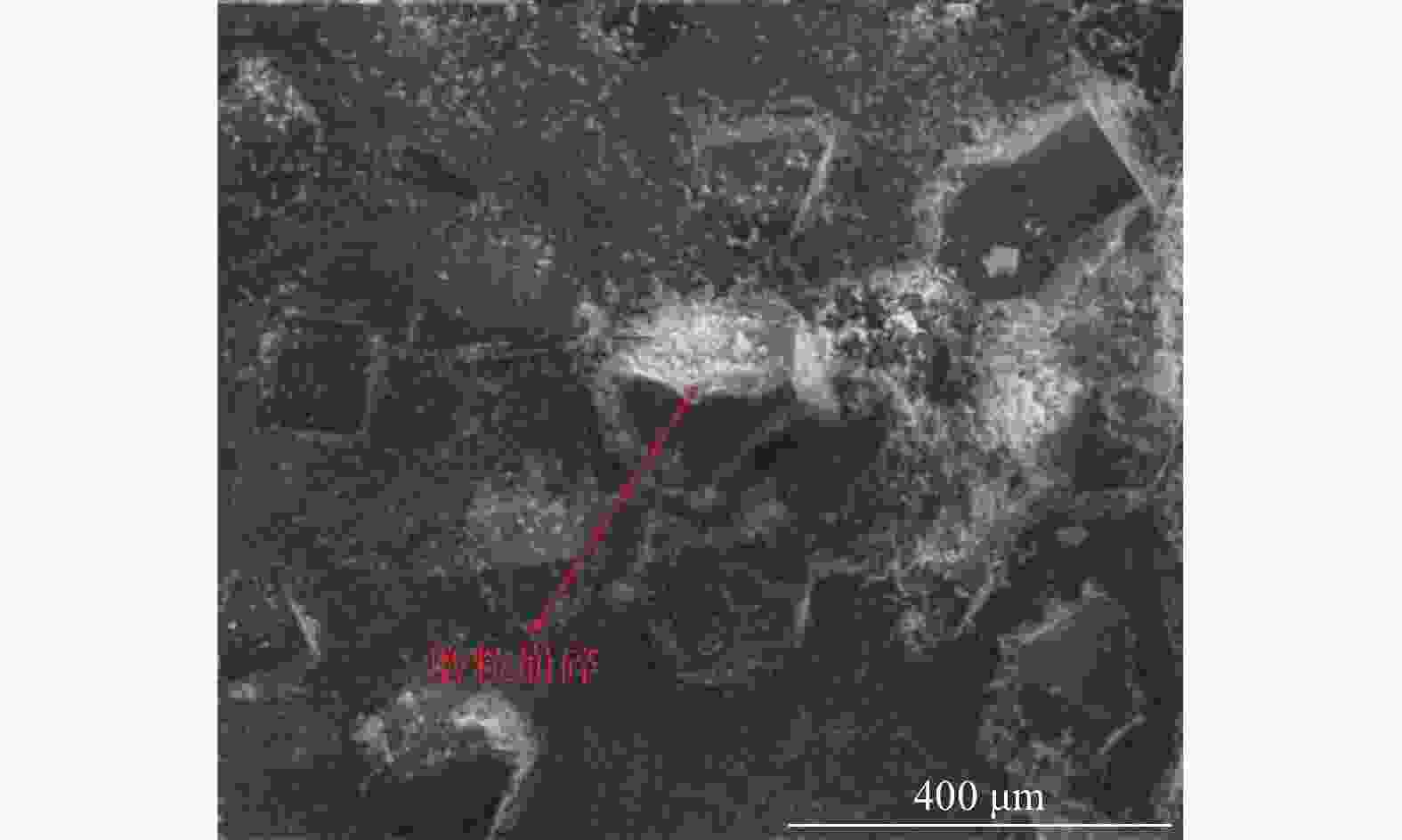

摘要: 针对石英纤维增强陶瓷基复合材料(SiO2f /SiO2)制造的薄壁壳体零件加工过程中存在加工效率低、切削力较大易导致零件破裂和加工表面粗糙度不易达到要求等问题,为寻求零件可行的加工刀具和工艺参数,在阐述微刃切削原理基础上,用其研制的整体多刃PCD刀具和电镀金刚石磨头,开展金刚石工具加工SiO2f/SiO2复合材料的可行性研究。结果表明:采用基于微刃切削原理设计的整体多刃PCD刀具加工SiO2f/SiO2,因刀具锋利和多刃特点可以实现较大的切深并获得较大的切削效率,但是切削力相对较大;相比于整体多刃PCD刀具,电镀金刚石磨头加工SiO2f/SiO2时切削力较小,加工后工件表面质量较好,且其表面粗糙度较低;

-

关键词:

- SiO2f/SiO2 /

- 切削力 /

- 表面粗糙度 /

- 表面质量

Abstract: The thin-wall shell parts manufactured by quartz fiber reinforced ceramic matrix composites have low machining efficiency and bigger cutting force, which can easily lead to broken parts and bad surface roughness not meeting the requirements. To solve these problems and seek feasible cutting tool and process parameters, based on the principles of micro cutting, the feasibility study of SiO2f/SiO2 was carried out by using the developed integral multi-edge PCD tool and electroplated diamond grinding tool. The experimental results show that the integral multi-edge PCD tool, designed based on the micro-edge cutting principle, can achieve a large cutting depth and a large cutting efficiency, but its cutting force is relatively huge. Compared with the integral multi-edge PCD tool, electroplated diamond grinding tool have lower cutting force, better surface quality and lower surface roughness.-

Key words:

- SiO2f/SiO2 /

- cutting force /

- surface roughness /

- surface quality

-

表 1 切削力测量单因素试验参数

Table 1. Single factor test parameters of cutting force measurement

加工条件 参数或取值 刀具 整体多刃PCD铣刀,

电镀金刚石磨头主轴转速 n / (r·min−1) 3 000,5 000,7 000,9 000 进给速度 vf / (mm·min−1) 20,40,60,80 切削深度 ap / mm 0.1,0.2,0.3,0.4 -

[1] 杜善义. 先进复合材料与航空航天 [J]. 复合材料学报,2007,24(1):1-12. doi: 10.3321/j.issn:1000-3851.2007.01.001DU Shanyi. Advanced composite materials and aerospace engineering [J]. Acta Materiae Compositae Sinica,2007,24(1):1-12. doi: 10.3321/j.issn:1000-3851.2007.01.001 [2] 冉冲, 卢守相, 高航, 等. 石英纤维增强陶瓷基复合材料制孔工艺研究 [J]. 金刚石与磨料磨具工程,2016,36(2):37-42.RAN Chong, LU Shouxiang, GAO Hang, et al. Research on drilling technology of quartz fiber reinforced ceramic matrix composites [J]. Diamond and Abrasives Engineering,2016,36(2):37-42. [3] 王玉果, 徐靖宇, 林彬. 石英纤维复合材料的磨削加工性能研究 [J]. 天津大学学报,2019,52(4):337-345.WANG Yuguo, XU Jingyu, LIN Bin, et al. Research on grinding properties of quartz fiber composites [J]. Journal of Tianjin University,2019,52(4):337-345. [4] ABRAO A M, CAMPOS R, FARIA P E, et al. The effect of cutting tool geometry on thrust force and delamination when drilling glass fiber reinforced plastic composite [J]. Materials & Design,2008,29:508-513. [5] ZHANG L C, ZHANG H J, WANG X M, et al. A force prediction model for cutting unidirectional fiber-reinforced plastics [J]. Machining Science and Technology,2006,20:293-305. [6] STEPHEN M, GUO C S. Grinding technology [M]. Industrial Press, 2008. [7] 何文豪. 面向机器人应用的碳纤维复合材料制孔技术研究 [D]. 大连: 大连理工大学, 2021.HE Wenhao. The research on drilling technology of carbon fiber composites for robot [D]. Dalian University of Technology, 2021. [8] 何涛, 傅玉灿, 苏宏华. C/SiC复合材料铣削表面完整性研究 [J]. 南京航空航天大学学报,2014,46(5):701-706. doi: 10.3969/j.issn.1005-2615.2014.05.006HE Tao, FU Yucan, SU Honghua. Study on surface integrity in milling of C/SiC composite [J]. Journal of Nanjing University of Aeronautics,2014,46(5):701-706. doi: 10.3969/j.issn.1005-2615.2014.05.006 [9] 康仁科, 赵凡, 鲍岩, 等. 超声辅助磨削SiCf/SiC陶瓷基复合材料 [J]. 金刚石与磨料磨具工程,2019,39(4):85-91.KANG Renke, ZHAO Fan, et al. Ultrasonic assisted grinding of SiCf/SiC composites [J]. Diamond & Abrasives Engineering,2019,39(4):85-91. [10] 刘杰, 李海滨, 张小彦, 等. 2D-C/SiC高速深磨磨削特性及去除机制 [J]. 复合材料学报,2012,29(4):113-118. doi: 10.13801/j.cnki.fhclxb.2012.04.038LIU Jie, LI Haibin, ZHANG Xiaoyan, et al. Investigation of grinding characteristics and removal mechanisms of 2D-C/SiC in high speed deep grinding [J]. Acta Materiae Compositae Sinica,2012,29(4):113-118. doi: 10.13801/j.cnki.fhclxb.2012.04.038 [11] 张幼桢. 金属切削原理及刀具 [M]. 北京: 国防工业出版社, 1990.ZHANG Youzhen. Metal cutting principle and cutting tool [M]. Beijing: National Defense Industry Press, 1990. [12] 濮建飞, 宦海祥, 徐九华, 等. PCD刀具车削钛合金复合材料的刀具磨损研究 [J]. 金刚石与磨料磨具工程,2020,40(5):11-16.PU Jianfei, HUAN Haixiang, XU Jiuhua, et al. Study on tool wear of PCD tool in turning titanium matrix composite [J]. Diamond & Abrasives Engineering,2020,40(5):11-16. [13] 宋伟. 基于声发射检测的旋转超声加工中金刚石磨头磨损的研究 [D]. 厦门: 华侨大学, 2021.SONG Wei. Study on wear of diamond grinding tool in rotary ultrasonic machining based on acoustic emission [D]. Xiamen: Huaqiao University, 2021. -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS