Application of brazed coating diamond in remanufacturing of shield cutters

-

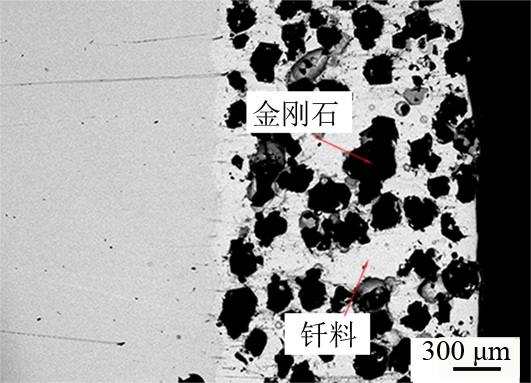

摘要: 采用感应钎焊的方法,在堆焊层上制备金刚石耐磨复合涂层。对涂层进行磨粒磨损实验,并通过体视显微镜、扫描电镜、能谱分析和磨损质量损失表征钎涂界面的组织和磨痕特征。结果表明:金刚石复合涂层形成良好,金刚石弥散分布在复合涂层中,钎料与堆焊层之间形成了约5 μm的钎焊反应界面,并实现良好的冶金结合;在相同磨损实验条件下,堆焊层的质量损失为0.601 2 g,钎涂金刚石再制造试件的质量损失为0.087 1 g,约为堆焊层的14.5%。Abstract: The diamond wear-resistant composite coating was prepared on the surfacing layer by induction brazing.The abrasive wear experiment was carried out on the coating, and the microstructure and wear scar characteristics of the brazing coating interface were characterized by stereomicroscope, scanning electron microscope, energy spectrum analysis and wear mass loss.The results show that the diamond composite coating is well formed, the diamond is dispersed in the composite coating, the brazing reaction interface about 5 μm is formed between the solder and the surfacing layer, and a good metallurgical bond is achieved.Under the same wear test conditions, the mass loss of the surfacing layer is 0.601 2 g, and the mass loss of the brazed diamond remanufactured specimen is 0.087 1 g, which is about 14.5% of the mass loss of the surfacing layer.

-

Key words:

- brazed coating /

- shield cutter /

- diamond /

- wear resistance

-

表 1 堆焊层化学成分

Table 1. Chemical compositions of surfacing layer

表 2 堆焊工艺参数

Table 2. Surfacing process parameters

表 3 NiCrBSi钎料化学成分

Table 3. Chemical compositions of NiCrBSi solder

-

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS