Effect of particle size of nano-diamond on wear and corrosion resistance of electroless Ni-P composite coatings

-

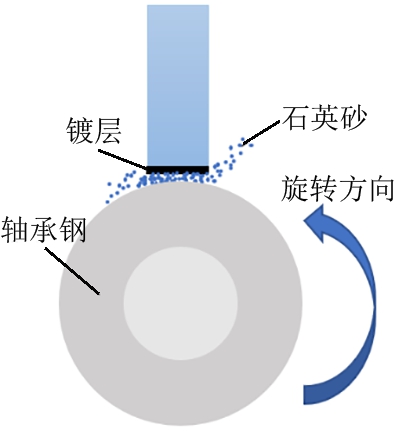

摘要: 为提高化学镀镀层的耐磨性和耐腐蚀性,采用化学镀制备含不同粒径的纳米金刚石Ni-P-D复合镀层,通过SEM、XRD、摩擦磨损试验、磨粒磨损试验和电化学试验,探究纳米金刚石粒径对Ni-P镀层微观形貌、力学性能、摩擦磨损性能、磨粒磨损性能和耐腐蚀性能的影响。经化学复合镀可以得到与基体结合良好,厚度约为30 μm,含纳米金刚石的Ni-P-D复合镀层;含50 nm 金刚石的Ni-P-D复合镀层的硬度最高,抗摩擦磨损和磨粒磨损性能最好;随着纳米金刚石粒径减小,Ni-P-D复合镀层的摩擦系数和抗腐蚀能力提高,含5 nm金刚石的Ni-P-D复合镀层的摩擦系数最小,抗腐蚀能力最强。

-

关键词:

- 化学复合镀 /

- 纳米金刚石 /

- Ni-P-D复合镀层 /

- 耐磨性 /

- 耐腐蚀性

Abstract: To improve the wear resistance and corrosion resistance of coatings, the Ni-P-D composite coatings which contained various size of nano-diamond particles were prepared by electroless plating.The effects of nano-diamond size on microstructure, mechanical properties, friction characteristics, abrasive wear performance and corrosion resistance of Ni-P coatings were investigated by SEM, XRD, tribological and abrasive wear testing as well as electrochemical experiment.It is discovered that the Ni-P-D composite coatings containing nano-diamond particles with thickness of about 30 μm and well bonding to the steel substrate could be obtained.Ni-P-D composite coating containing 50 nm diamond particles has the highest hardness, the best friction wear resistance and abrasive wear resistance.With the decrease of nano-diamond particle's size, the coefficient of friction decreases, and the corrosion resistance of Ni-P-D composite coating increases.Ni-P-D composite coating containing 5 nm diamond particles has the lowest coefficient of friction and strongest corrosion resistance. -

表 1 Ni-P镀液配方

Table 1. Formula of the Ni-P plating solution

表 2 镀层电化学极化参数

Table 2. Electrochemical polarization parameters of different coatings

-

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS