Preparation and properties of nickel-boron-diamond ultrathin dicing blades

-

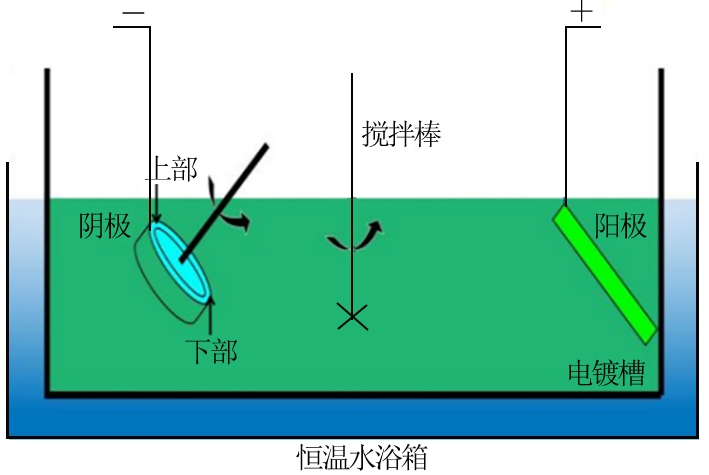

摘要: 在氨基磺酸镍体系电镀液中添加不同浓度的三甲胺硼烷(TMAB),在阴极自旋转状态下利用复合电沉积方法制备不同质量分数的硼的镍-硼/金刚石切割片,探究镀液中不同质量浓度的TMAB对切割片晶体结构、硬度、耐磨性的影响。结果表明:阴极自旋转状态下制备的镍-硼/金刚石切割片中金刚石分布均匀;随TMAB质量浓度增加,镀层的晶粒尺寸减小、硬度增加、耐磨性提高。当TMAB质量浓度为3.0 g/L时,镀层基质金属的晶粒尺寸最小为6.84 nm,硬度最大为2 453.6 HV,磨损量最小为1.7×10-2 mm3,磨损宽度最小为665.4 μm。用厚度为28.3 μm的镍-硼/金刚石切割片切割(111)晶面的N型单晶硅片,硅片切割槽宽度为35.3 μm,切缝比为1.25,最大崩边尺寸为3.1 μm。Abstract: Diverse concentrations of trimethylamine borane(TMAB)were added into the nickel sulfamate electrolyte.The Ni-B-diamond dicing blades with different boron content were prepared by composite electrodeposition under the state of spinning the cathode.The influence of different concentrations of TMAB on the crystal structure, the hardness, and the wear resistance of the dicing blades were explored.The results show that the diamond on the dicing blades prepared under the spinning state of the cathode is distributed uniformly.With the increase of TMAB mass concentration, the grain size is decreased, the hardness and the wear resistance is improved.When the TMAB mass concentration is 3.0 g/L, the minimum grain size of the substrate metal is 6.84 nm, the maximum hardness is 2 453.6 HV, the minimum wear is 1.7×10-2 mm3,and the minimum wear width is 665.4 μm.The Ni-B-diamond cutting disc with a thickness of 28.3 μm is used to cut the N-type single crystal silicon wafer with a crystal plane of(111).The groove width of the silicon wafer is 35.3 μm, the ratio of groove width to knife thickness is 1.25, and the maximum chipping size is 3.1 μm.

-

Key words:

- ultrathin dicing blades /

- nickel-boron diamond /

- hardness /

- wear loss

-

表 1 电沉积溶液化学成分

Table 1. Chemical compositions of electrodeposition solution

表 2 镍-硼/金刚石超薄切割片制备工艺参数

Table 2. Preparation process parameters of nickel-boron-diamond ultra-thin cutting discs

-

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS