Cutting edge trimming of high speed steel milling cutter based on shear thickening fluid

-

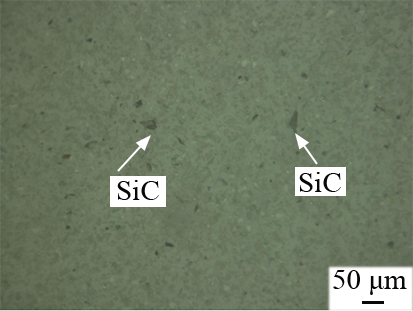

摘要: 为研究剪切增稠抛光液对铣刀刃口的影响,以四刃高速钢平头立铣刀为研究对象,对高速钢刀具进行修整,测量铣刀刃口半径,并观测铣刀前刀面、后刀面以及刃口形貌。试验结果表明:修整后,铣刀刃口半径减小,但由于不同切削刃初始状态不同,刃口半径减小的程度不同,最大变化量为7.5 μm,最小变化量为0.4 μm;修整试验只是针对铣刀刃口进行修整,铣刀的前、后刀面无明显变化,磨削痕迹并没有去除;磨料粒度对修整效果有一定影响,a组、b组和c组碳化硅STF试验组修整后,平均刃口半径分别减小4.6、3.6和1.9 μm,磨粒尺寸越大,铣刀刃口半径变化越明显。Abstract: To study the effect of shear thickening polishing fluid on the cutting edge of milling cutter, a four-edge high speed steel flat end milling cutter was taken as the research object, and the high speed steel cutter was trimmed.The cutting edge radius of the milling cutter was measured and the cutting edge morphology of the milling cutter was observed.The experimental results showed that the cutting edge radius decreased after trimming, but the cutting edge radius decreased to different degrees due to the different initial states.The maximum change was 7.5 μm, and the minimum change was 0.4 μm.In the trimming experiment, only the cutting edge of the milling cutter was trimmed.The front and back face of the milling cutter did not change obviously.The grinding marks were not removed.Abrasive particle size had a certain influence on the trimming effect.After trimming, the average cutting radius of a, b and c three silicon carbide STF experimental groups decreased by 4.6 μm, 3.6 μm and 1.9 μm, respectively.The larger the grinding particle size was, the more obvious the change of milling cutter edge radius was.

-

Key words:

- cutting tool trimming /

- shear thickening fluid /

- radius of edge /

- cutting edge morphology

-

表 1 STF试验组铣刀刃口平均半径变化

Table 1. Variation of average cutting edge radius of milling cutter in STF experiment group

-

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS