Drilling of C/SiC composite micro holes with electroplated diamond bits

-

摘要:

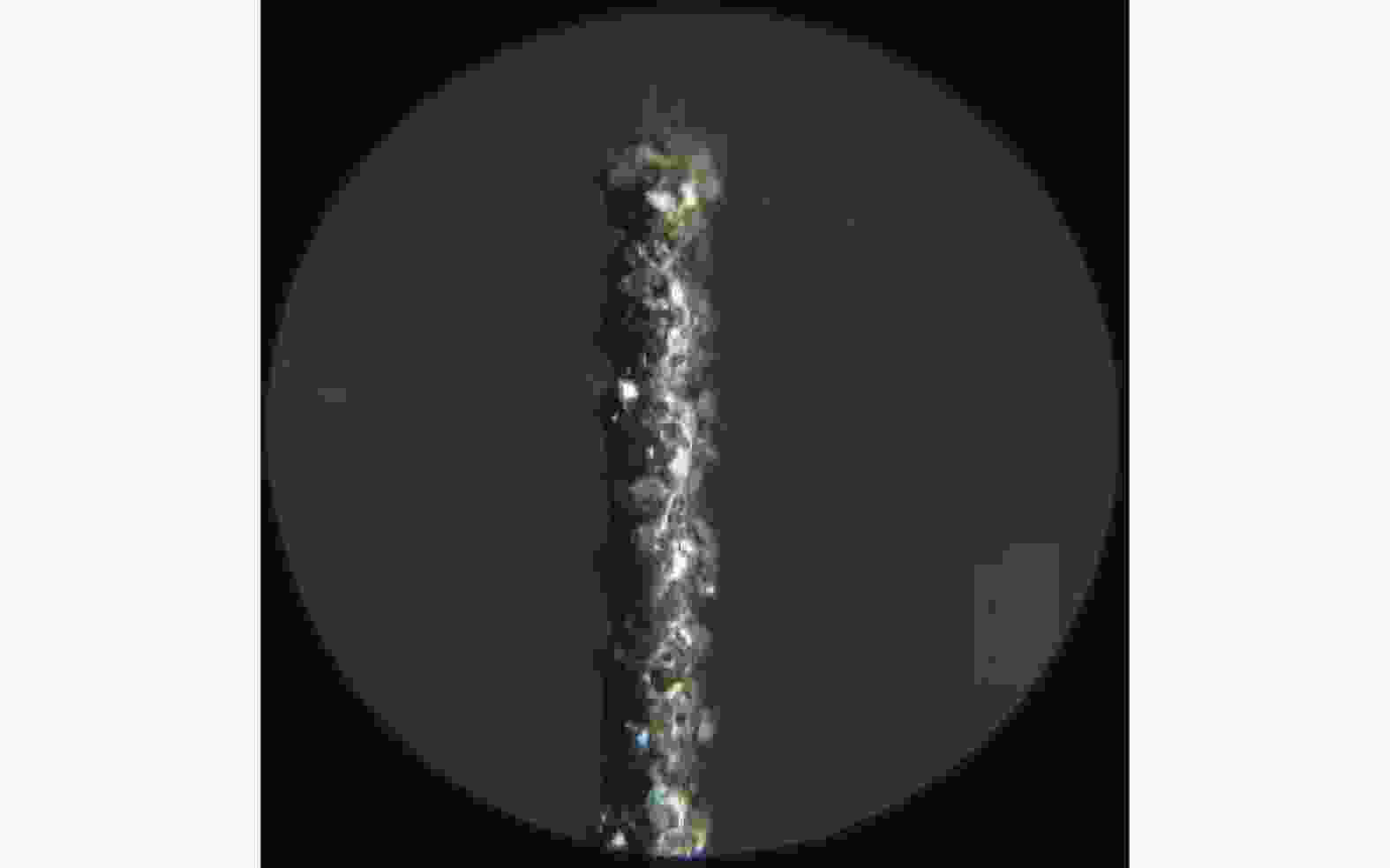

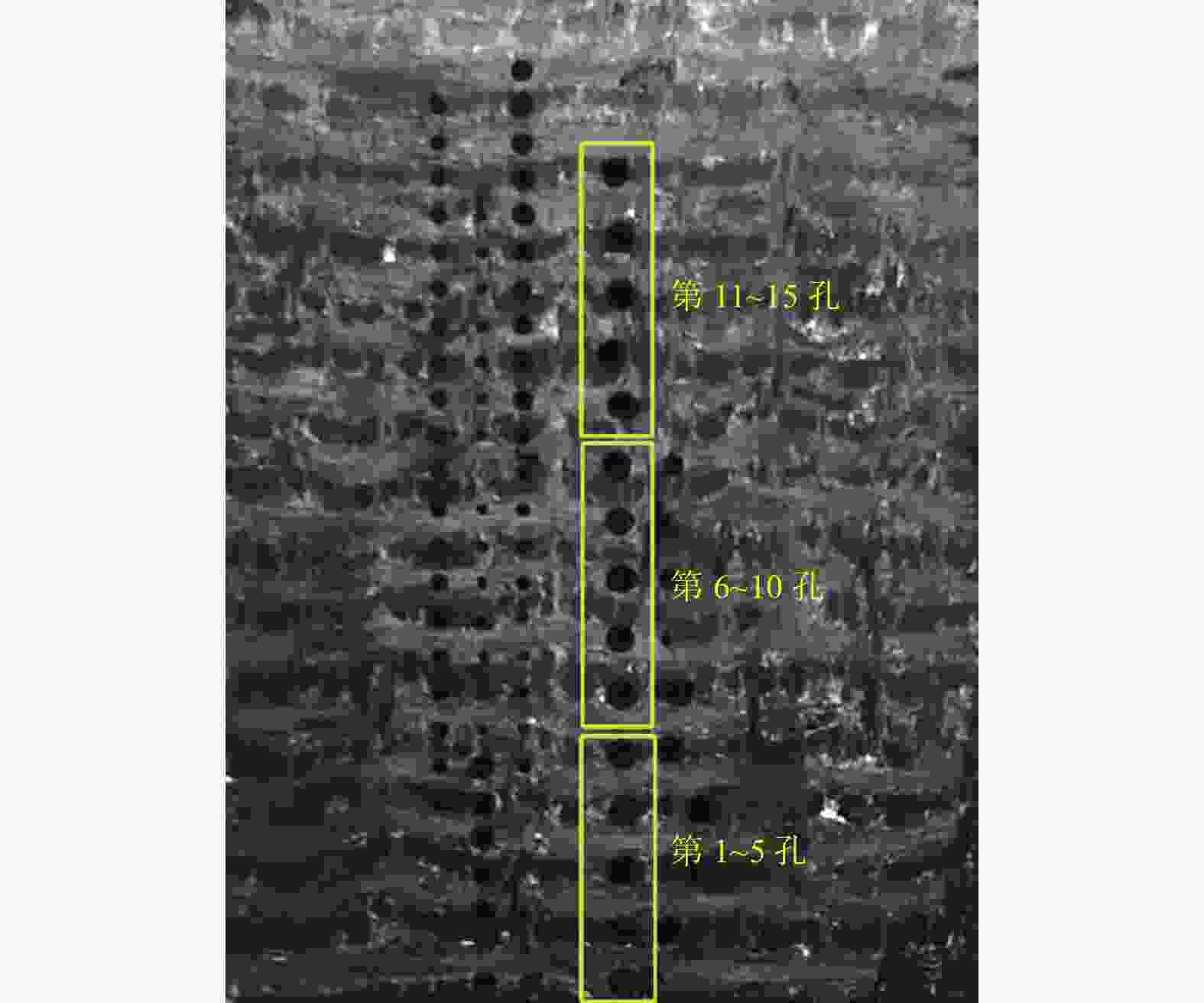

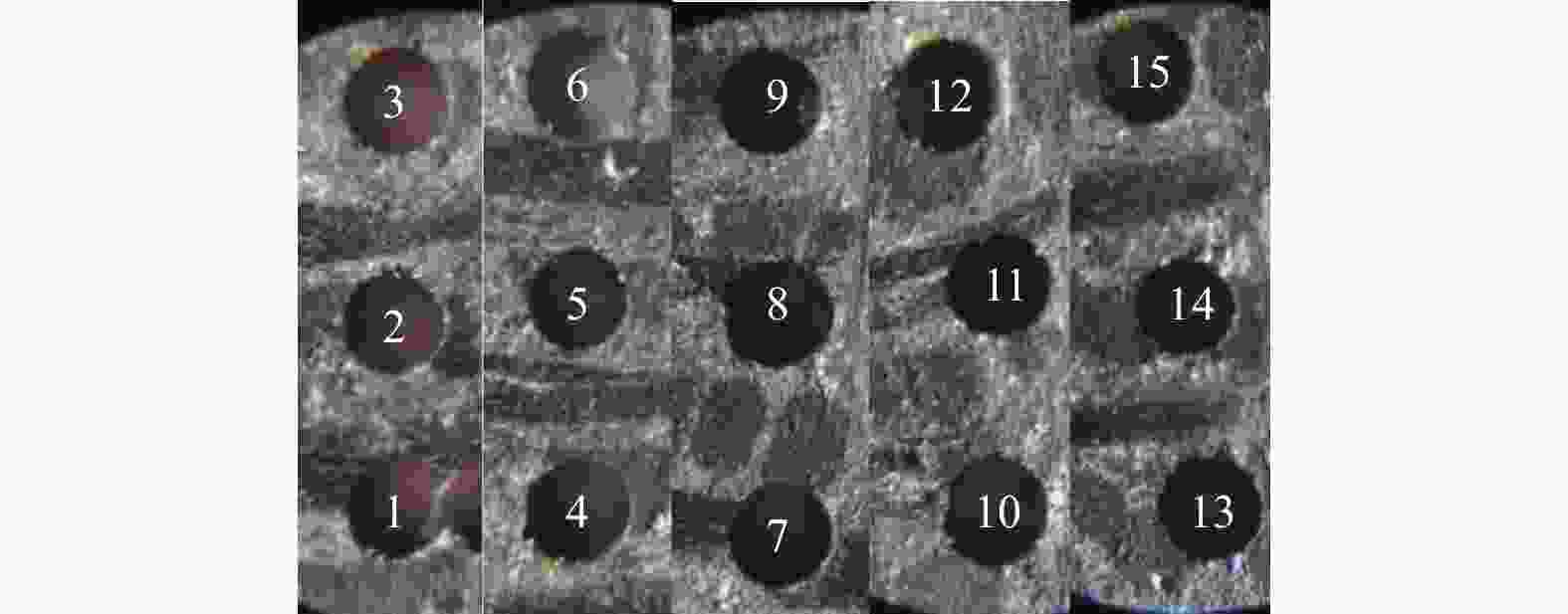

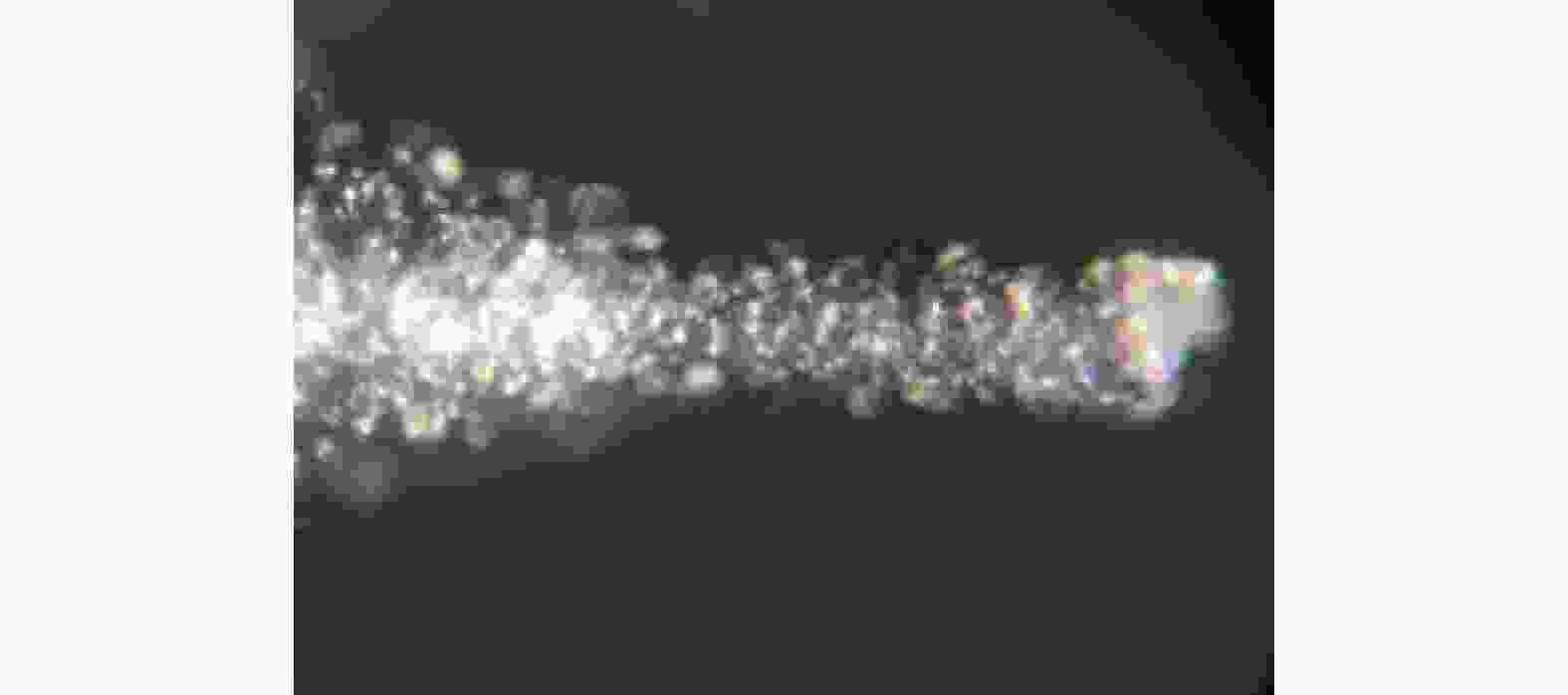

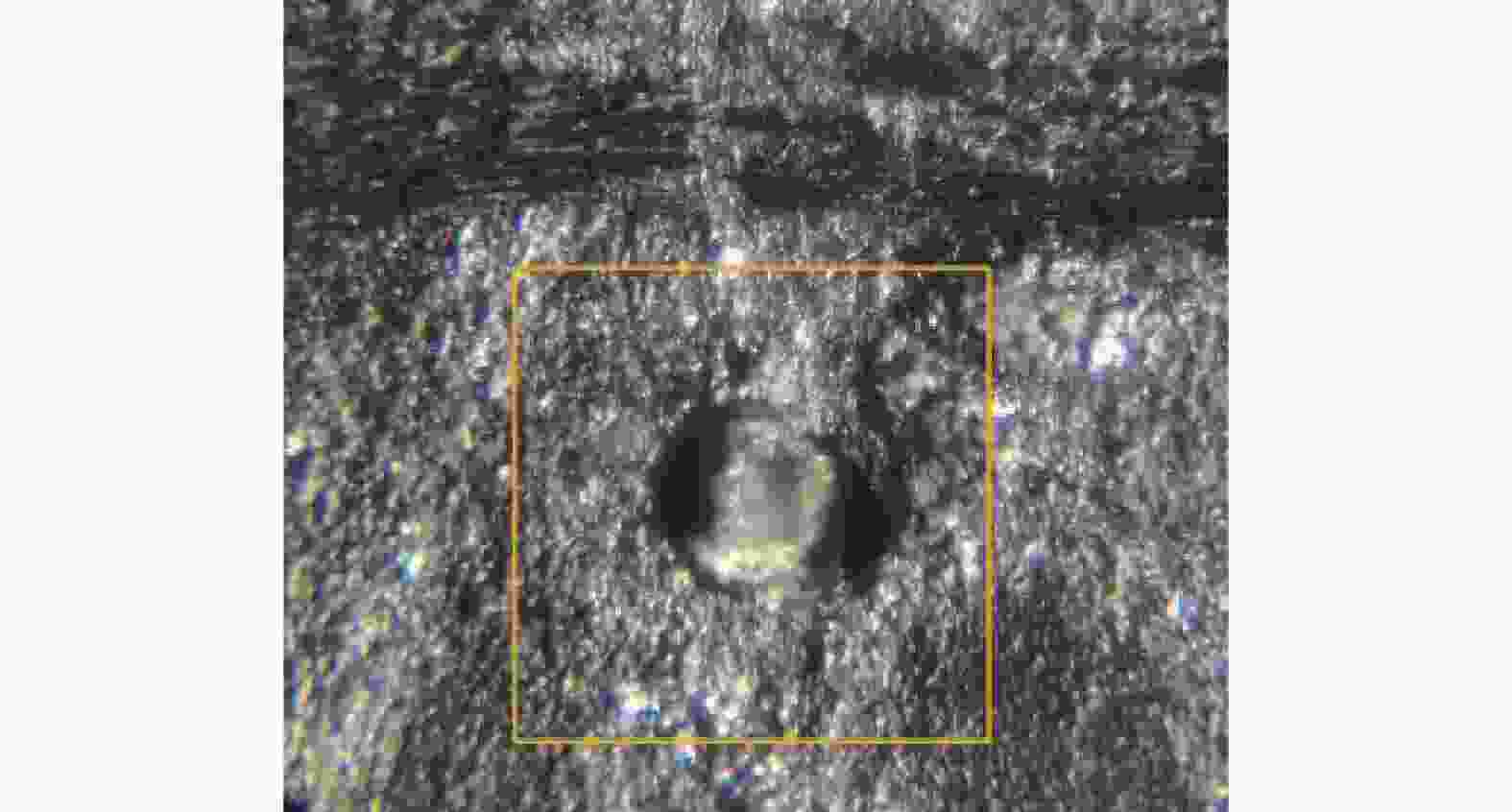

用金刚石基本颗粒尺寸分别为20~30,36~54和63~75 μm,直径在0.280~0.440 mm范围的6种电镀金刚石钻头,钻削三维针刺毡基C/SiC复合材料微孔,测试6种钻头的最佳加工工艺参数,分析工艺参数及金刚石基本颗粒尺寸、钻头直径等对微孔加工质量、加工效率的影响。结果表明:在相同钻削速度条件下,进给速度越低时,加工的微孔质量越好;钻头电镀的金刚石磨粒基本颗粒尺寸越大,其钻削效率越高;在6种钻头中,直径为0.300 mm的基体上电镀63~75 μm的磨粒,直径为0.200 mm的基体上电镀36~54 μm的磨粒,能够获得更优的钻孔性能。

Abstract:Six kinds of diamond electroplated bits, whose diameters were 0.280~0.440 mm and the basic particle sizes of diamond were 20~30, 36~54 and 63~75 μm, were used to drill micro holes of three-dimensional needle-punched felt-based C/SiC composite materials. The optimum processing parameters of the six kinds of bits were tested, and the influences of the process parameters, the diamond basic particle size and the bit diameter on the processing quality and efficiency of micro holes were analyzed. The results show that at the same drilling speed, the lower the feed speed is, the better the micro-hole quality is. The larger the basic particle size of electroplated diamond grains on the bit is, the higher the drilling efficiency is. In the six kinds of bits, the better drilling performances can be obtained by electroplating 63~75 μm abrasive particles on 0.300 mm diameter substrate and 36~54 μm abrasive particles on 0.200 mm diameter substrate.

-

Key words:

- C/SiC composites /

- micro hole processing /

- diamond electroplated bit /

- drilling

-

表 1 钻头规格表

Table 1. Specifications of drills

编号 基体

直径

D1 / mm钻头

外径

D2 / mm金刚石颗粒

基本尺寸

D3 / μm金刚石浓度

c / (颗·mm−1)钻头有效

长度

L / mm1# 0.200 0.283 20~30 230~260 3.5 2# 0.200 0.331 36~54 60~90 3.5 3# 0.200 0.358 63~75 20~40 3.5 4# 0.300 0.386 20~30 360~390 5.5 5# 0.300 0.428 36~54 100~130 5.5 6# 0.300 0.437 63~75 40~60 5.5 表 2 钻削试验方案

Table 2. Drilling test scheme

编号 钻削速度

vs / (m·min−1)进给速度

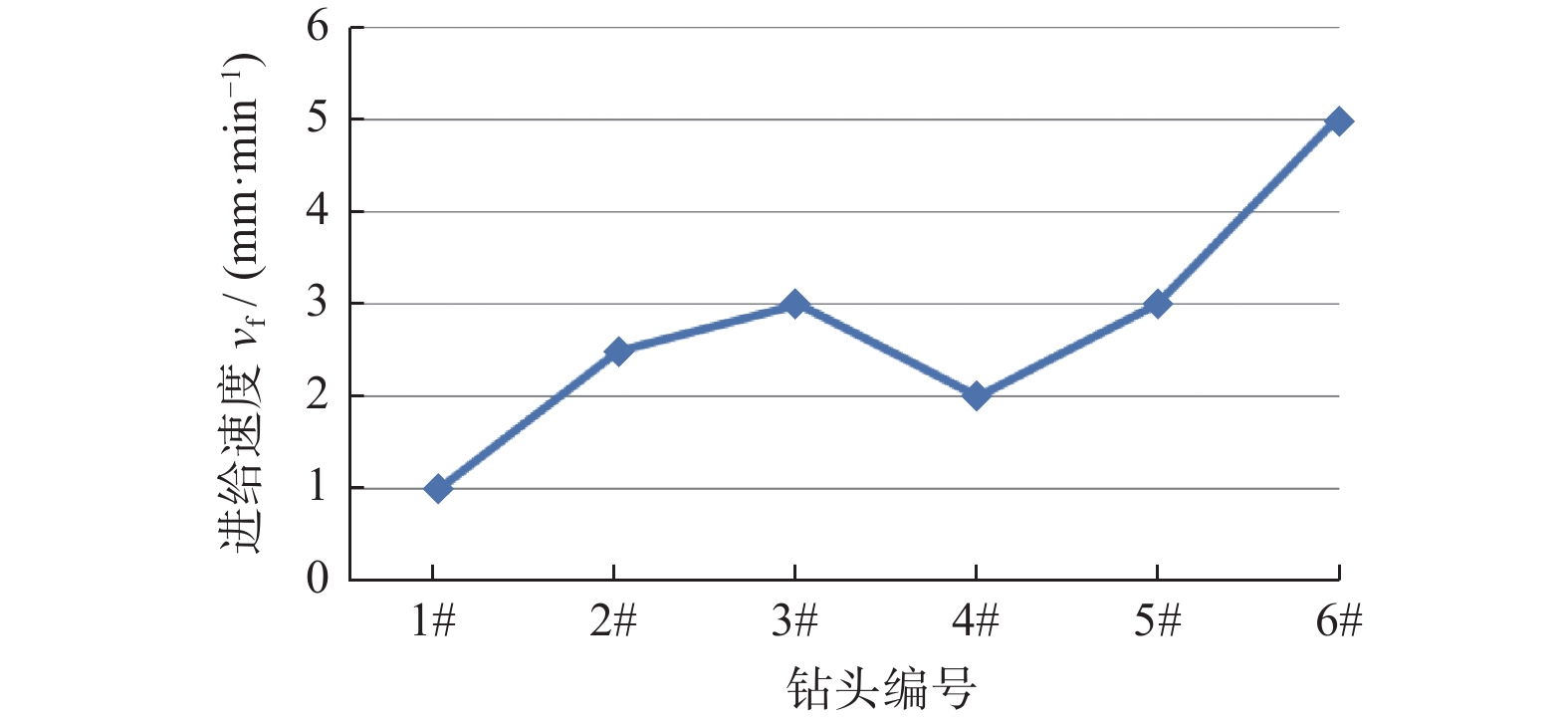

vf / (mm·min−1)1 16.0 2.0 2 11.0 2.0 3 8.0 2.0 4 5.5 2.0 5 4.0 2.0 6 16.0 3.0 7 11.0 3.0 8 8.0 3.0 9 5.5 3.0 10 4.0 3.0 11 16.0 5.0 12 11.0 5.0 13 8.0 5.0 14 5.5 5.0 15 4.0 5.0 表 3 钻头最佳工艺参数

Table 3. Optimum technological parameters of bits

钻头编号 钻削速度

vs / (m·min−1)进给速度

vf / (mm·min−1)单步切深

ap / mm最佳值 最大允许值 1# 16.0 0.5 1.0 0.01 2# 16.0 2.0 2.5 0.03 3# 16.0 2.0 3.0 0.04 4# 16.0 1.5 2.0 0.02 5# 16.0 2.0 3.0 0.04 6# 16.0 3.0 5.0 0.05 -

[1] 张瑾瑜, 王宁, 赵建设, 等. C/SiC复合材料螺旋铣削与钻削制孔效果对比 [J]. 宇航材料工艺,2020,50(5):39-43.ZHANG Jinyu, WANG Ning, ZHAO Jianshe, et al. Comparison between helical milling and drilling of C/SiC composite materials [J]. Aerospace Materials & Technology,2020,50(5):39-43. [2] 王丹. 硬脆非金属材料微结构微细加工关键技术研究 [D]. 上海: 上海交通大学, 2011.WANG Dan. Research on key techniques of micro machining of micro-structure on hard and brittle non-metallic materials [D]. Shanghai: Shanghai Jiao Tong University, 2011. [3] 龙慧玲, 蔡元沛. 提高玻璃钻孔金刚石工具钻孔性能的研究 [J]. 超硬材料工程,2010,22(6):20-23. doi: 10.3969/j.issn.1673-1433.2010.06.006LONG Huiling, CAI Yuanpei. Research on improving the performances of diamond tool for drilling glass [J]. Superhard Material Engineering,2010,22(6):20-23. doi: 10.3969/j.issn.1673-1433.2010.06.006 [4] 湛青坡, 刘含莲, 黄传真, 等. 超声振动辅助铣磨加工工艺对Cf/SiC复合材料加工表面质量的影响 [J]. 工具技术,2019,53(2):17-21. doi: 10.3969/j.issn.1000-7008.2019.02.004ZHAN Qingpo, LIU Hanlian, HUANG Chuanzhen, et al. Effect of ultrasonic vibration assisted mill-grinding technology on surface quality of Cf/SiC composite [J]. Tool Engineering,2019,53(2):17-21. doi: 10.3969/j.issn.1000-7008.2019.02.004 [5] 鲍永杰, 高航, 李凤全. 电镀金刚石钻头钻削碳纤维复合材料研究 [J]. 金刚石与磨料磨具工程,2009(3):38-42. doi: 10.3969/j.issn.1006-852X.2009.03.009BAO Yongjie, GAO Hang, LI Fengquan. Researchs on drilling CFRP(carbon fiber reinforced plastics)with diamond electroplated drill bit [J]. Diamond & Abrasives Engineering,2009(3):38-42. doi: 10.3969/j.issn.1006-852X.2009.03.009 [6] 陈意, 柏有才. 微孔复合加工技术进展 [J]. 内燃机与配件,2021(6):20-21. doi: 10.3969/j.issn.1674-957X.2021.06.010CHEN Yi, BO Youcai. Progress in microporous composite processing technology [J]. Internal Combustion Engine & Parts,2021(6):20-21. doi: 10.3969/j.issn.1674-957X.2021.06.010 [7] 张国栋, 邓建新, 张克栋, 等. C/C-SiC复合材料钻削加工工艺研究 [J]. 工具技术,2014,48(9):12-16. doi: 10.3969/j.issn.1000-7008.2014.09.004ZHANG Guodong, DENG Jianxin, ZHANG Kedong, et al. Study of technique in drilling C/C-SiC composites [J]. Tool Engineering,2014,48(9):12-16. doi: 10.3969/j.issn.1000-7008.2014.09.004 [8] 赵鹏, 黄树涛, 周丽. 电镀金刚石钻头钻削高体积分SiCp/Al复合材料入口棱边缺陷的研究 [J]. 金刚石与磨料磨具工程,2012,32(4):37-41.ZHAO Peng, HUANG Shutao, ZHOU Li. Research on entrance edge defect when drilling high volume fraction SiCp/Al composites with diamond electroplated drill bit [J]. Diamond & Abrasives Engineering,2012,32(4):37-41. [9] 邵国栋, 史振宇. 钎焊金刚石磨粒钻钻削C/SiC陶瓷基复合材料孔时切屑对钻削过程的影响 [J]. 金刚石与磨料磨具工程,2022,42(3):348-355. doi: 10.13394/j.cnki.jgszz.2021.0212SHAO Guodong, SHI Zhenyu. Effect of chips on drilling process when drilling C/SiC ceramic matrix composite holes with brazed diamond abrasive drill [J]. Diamond & Abrasives Engineering,2022,42(3):348-355. doi: 10.13394/j.cnki.jgszz.2021.0212 -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS