Experimental study on optimization of PDC cutting teeth for conglomerate layer

-

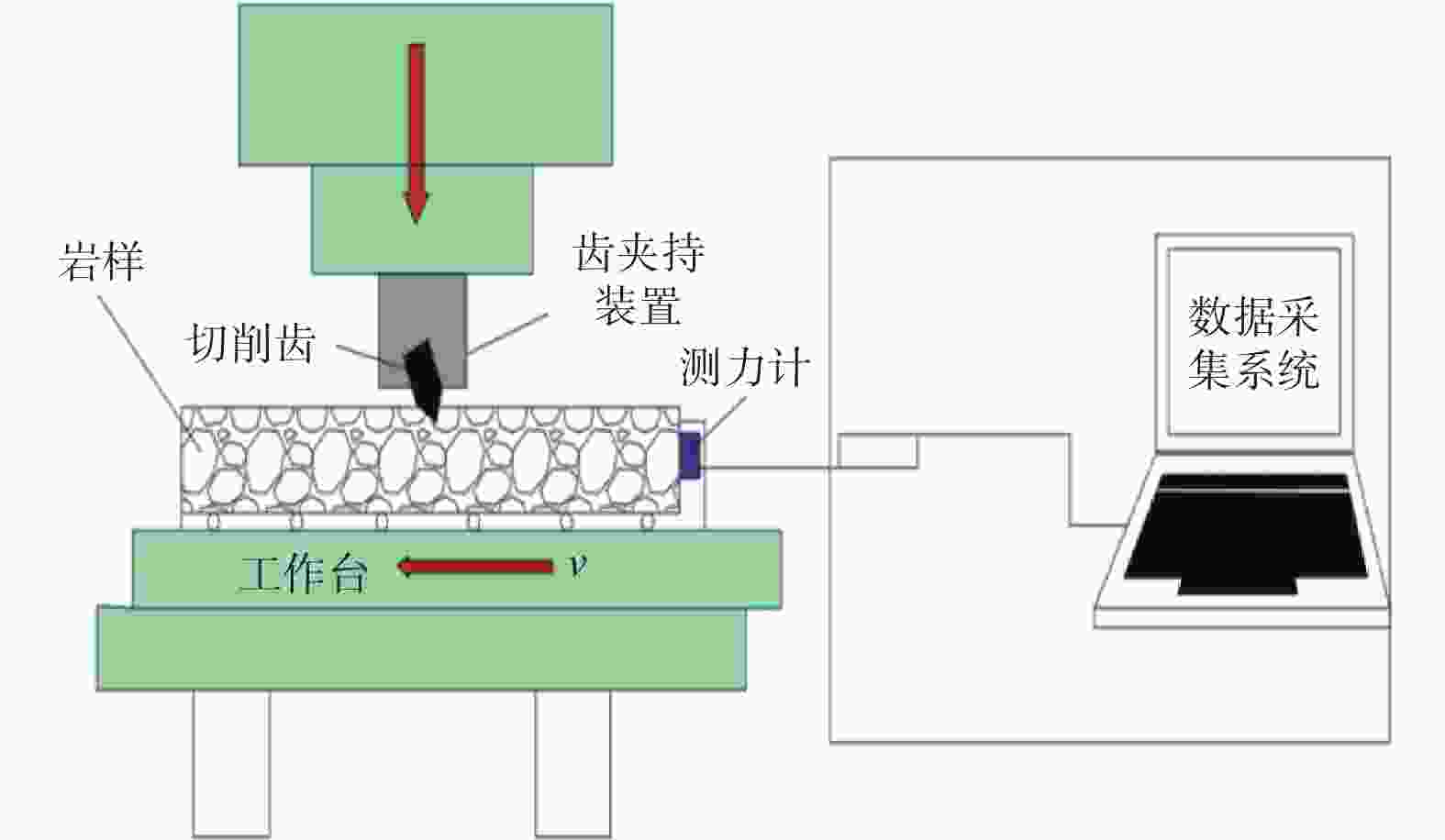

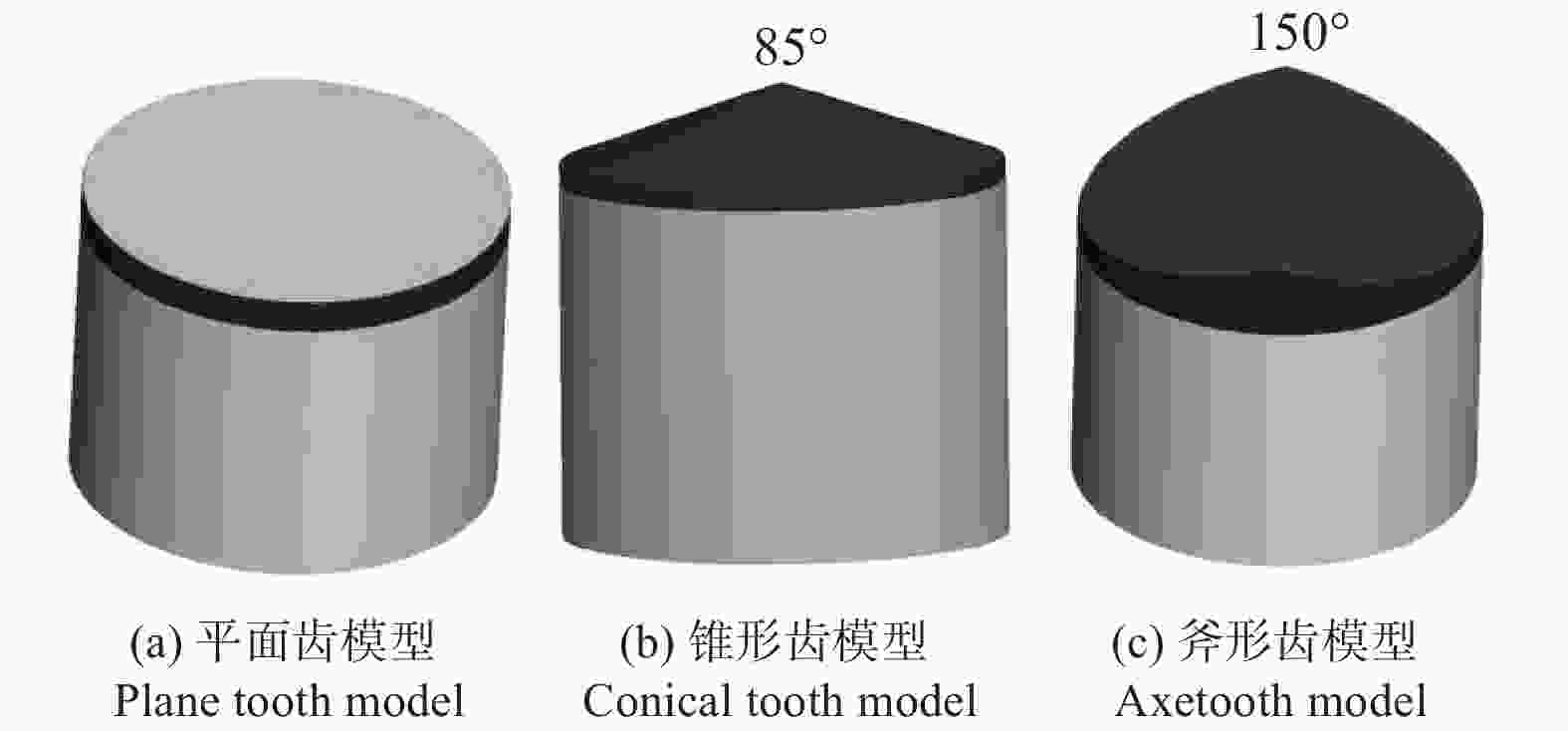

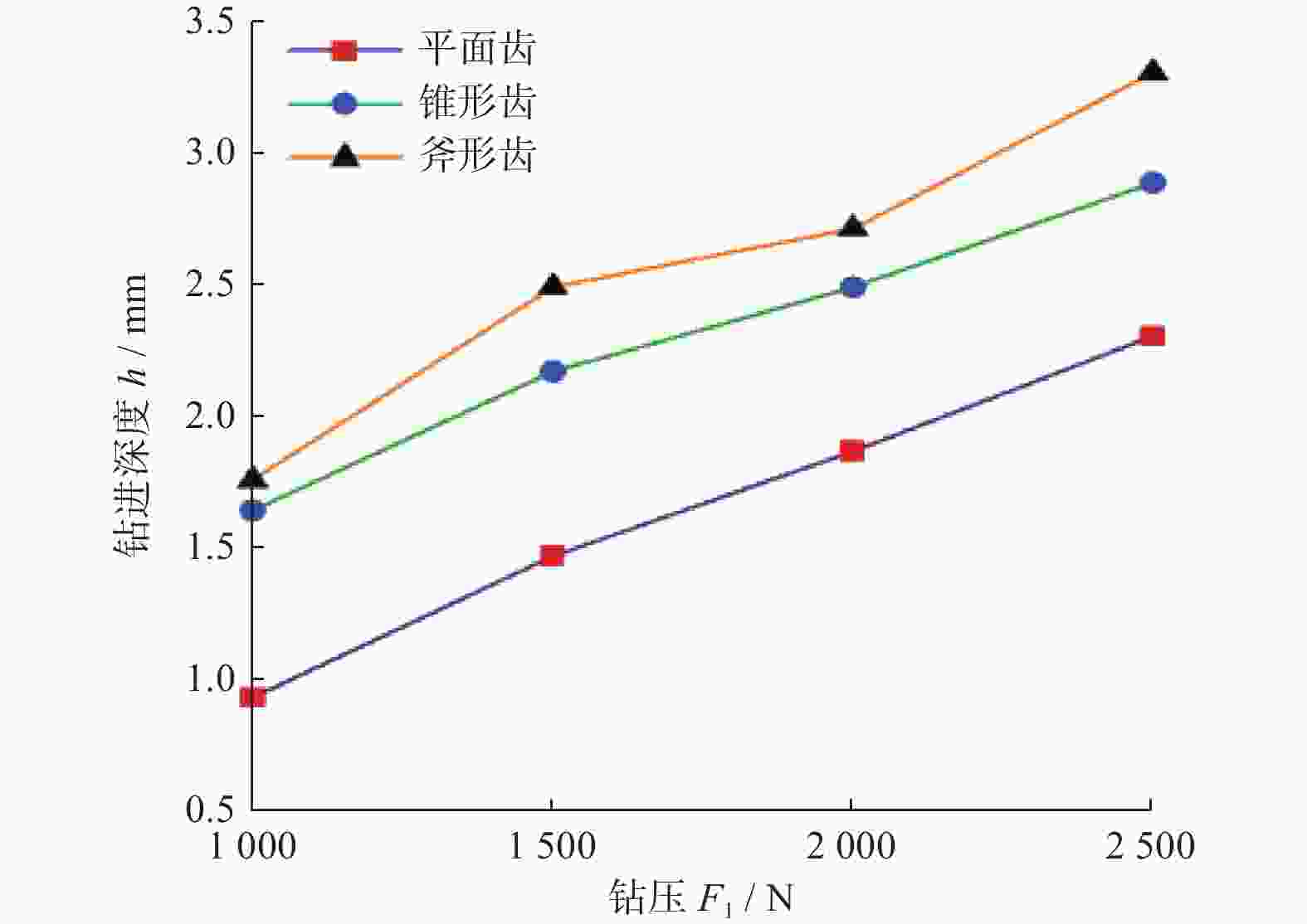

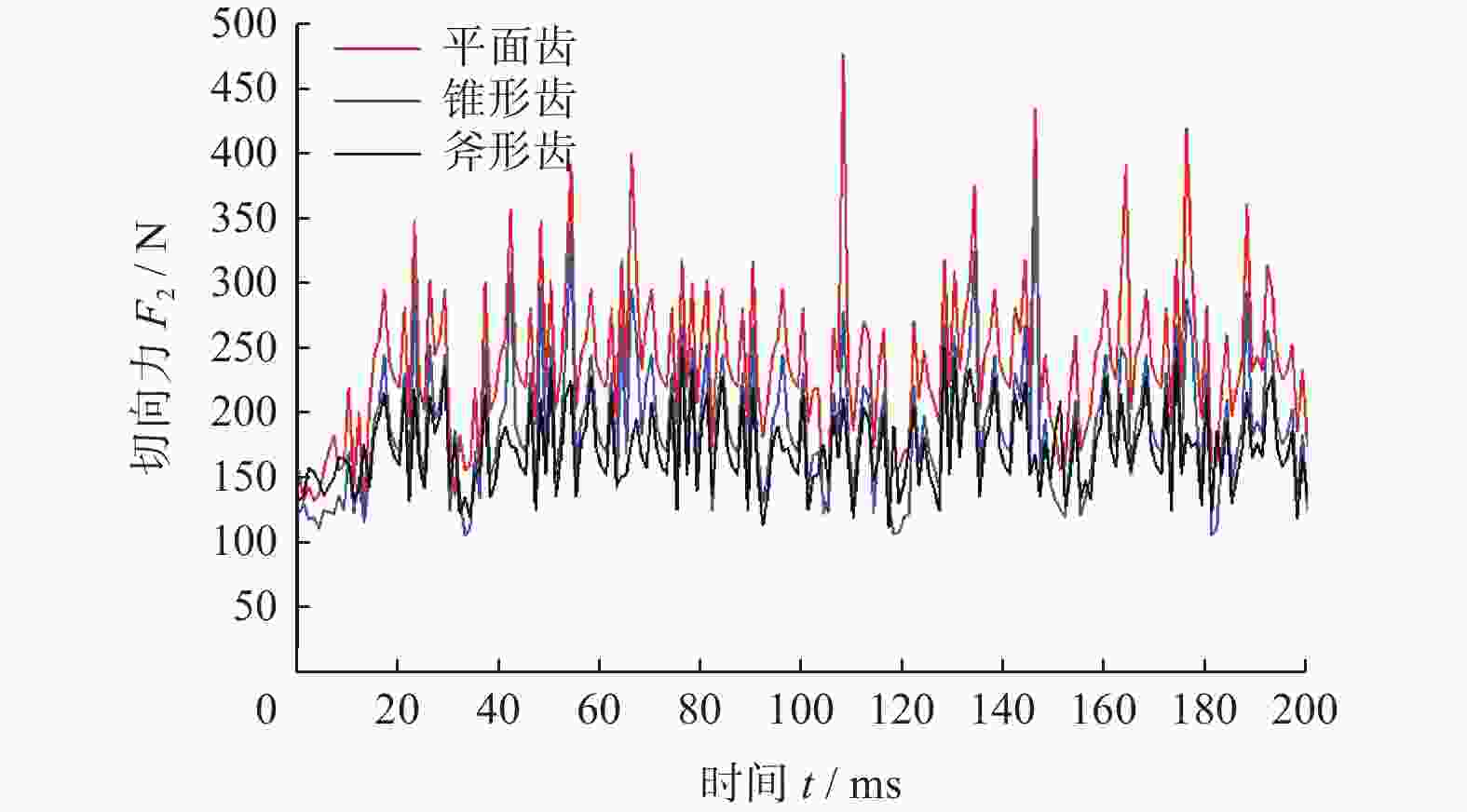

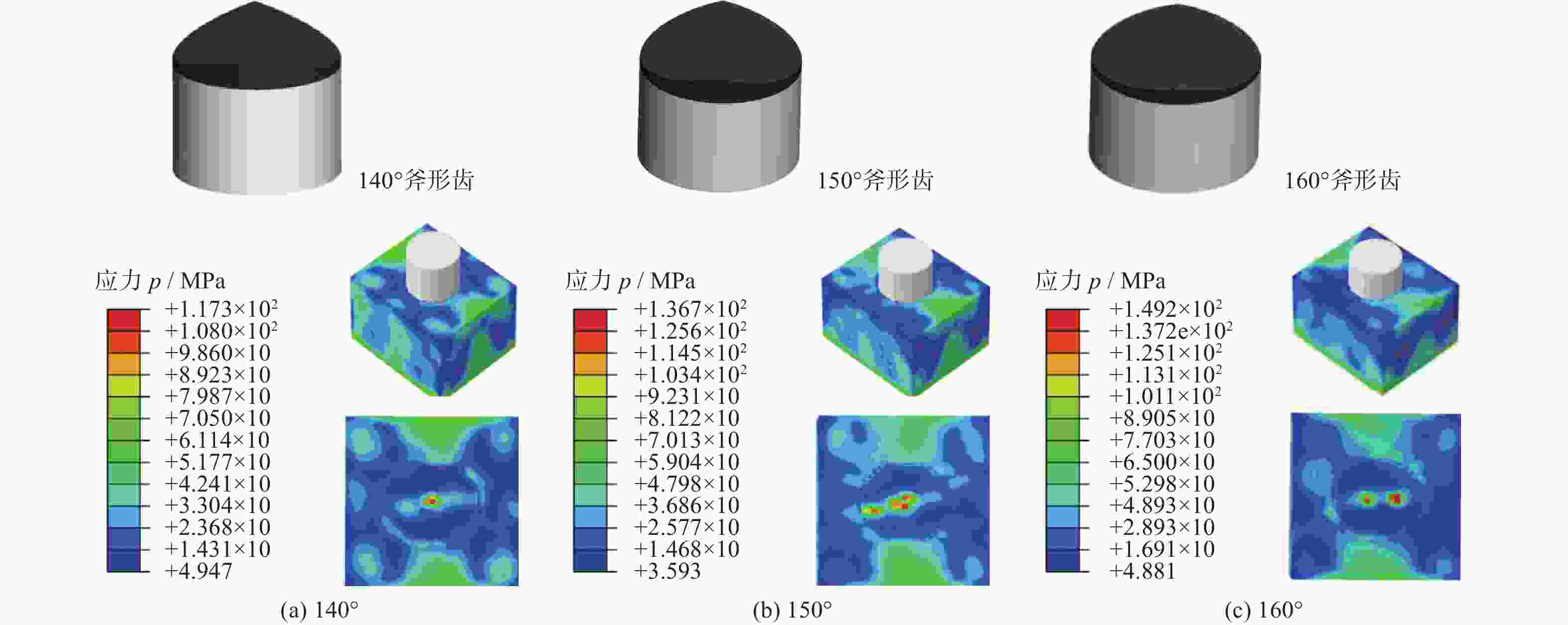

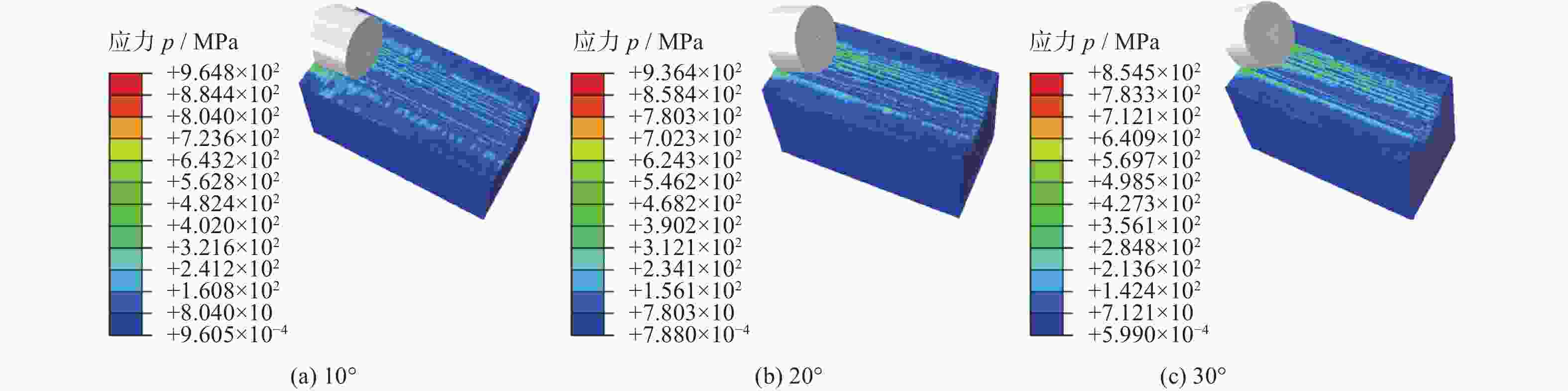

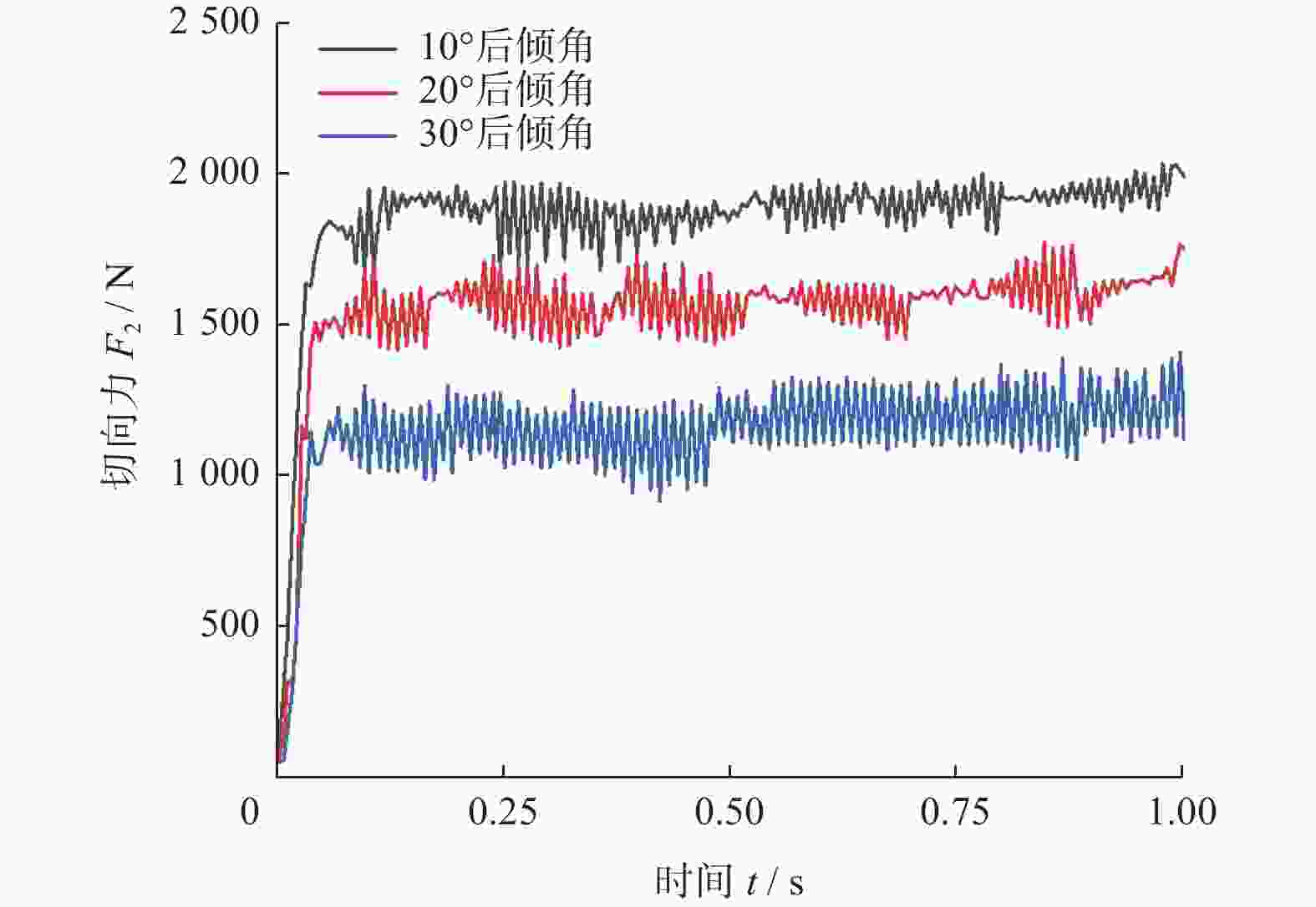

摘要: 为了在砾岩层中获得更好的钻进效果,需要对砾岩层用PDC钻头切削齿的齿形和后倾角进行优选。对普通平面齿、锥形齿和斧形齿在砾岩岩样中进行单齿破岩试验,再对优选出的斧形齿进行仿真分析,优选斧形齿的最佳齿面角度,再与普通平面齿进行切削模拟,验证试验结果。结果表明:斧形齿在砾岩层中切削效率最高,受力最稳定;齿面角度为140°的斧形齿在砾岩中钻进效果更好,当其配合30°后倾角时,切削效率最高。Abstract: In order to obtain better drilling effect in the conglomerate layer, it is necessary to optimize the tooth shape and caster angle of PDC bit for the conglomerate layer. Single tooth rock breaking experiments are conducted on ordinary plane teeth, conical teeth and axe teeth in the conglomerate rock sample. Then the simulation analysis is conducted on the optimized axe teeth to optimize the optimal tooth surface angle of axe teeth. And the cutting simulation is conducted with ordinary plane teeth to verify the experimental results. The results show that the axe tooth has the highest cutting efficiency and the most stable stress in the conglomerate layer; the drilling effect of 140° axe tooth in conglomerate is better; and the cutting efficiency is the highest when 140° axe teeth are matched with 30° caster angle. Therefore, when optimizing the cutting tools for the conglomerate layer, it is necessary to reasonably select the teeth according to the formation characteristics. When applying axe teeth, in order to achieve high cutting efficiency, it is necessary to optimize the combination of tooth surface angle and caster angle.

-

Key words:

- conglomerate /

- PDC cutting teeth /

- tooth profile optimization /

- special shaped teeth /

- ABAQUS

-

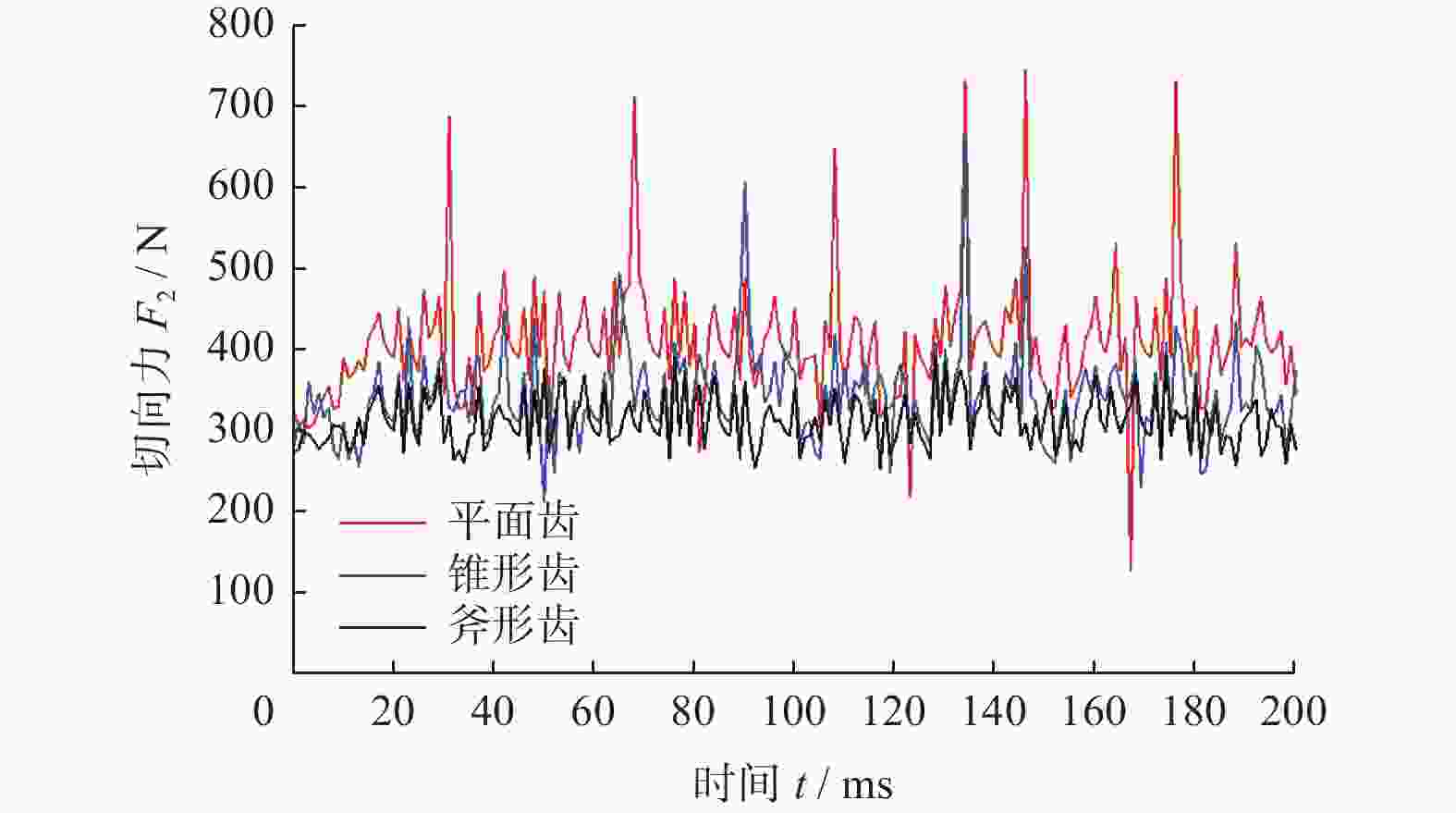

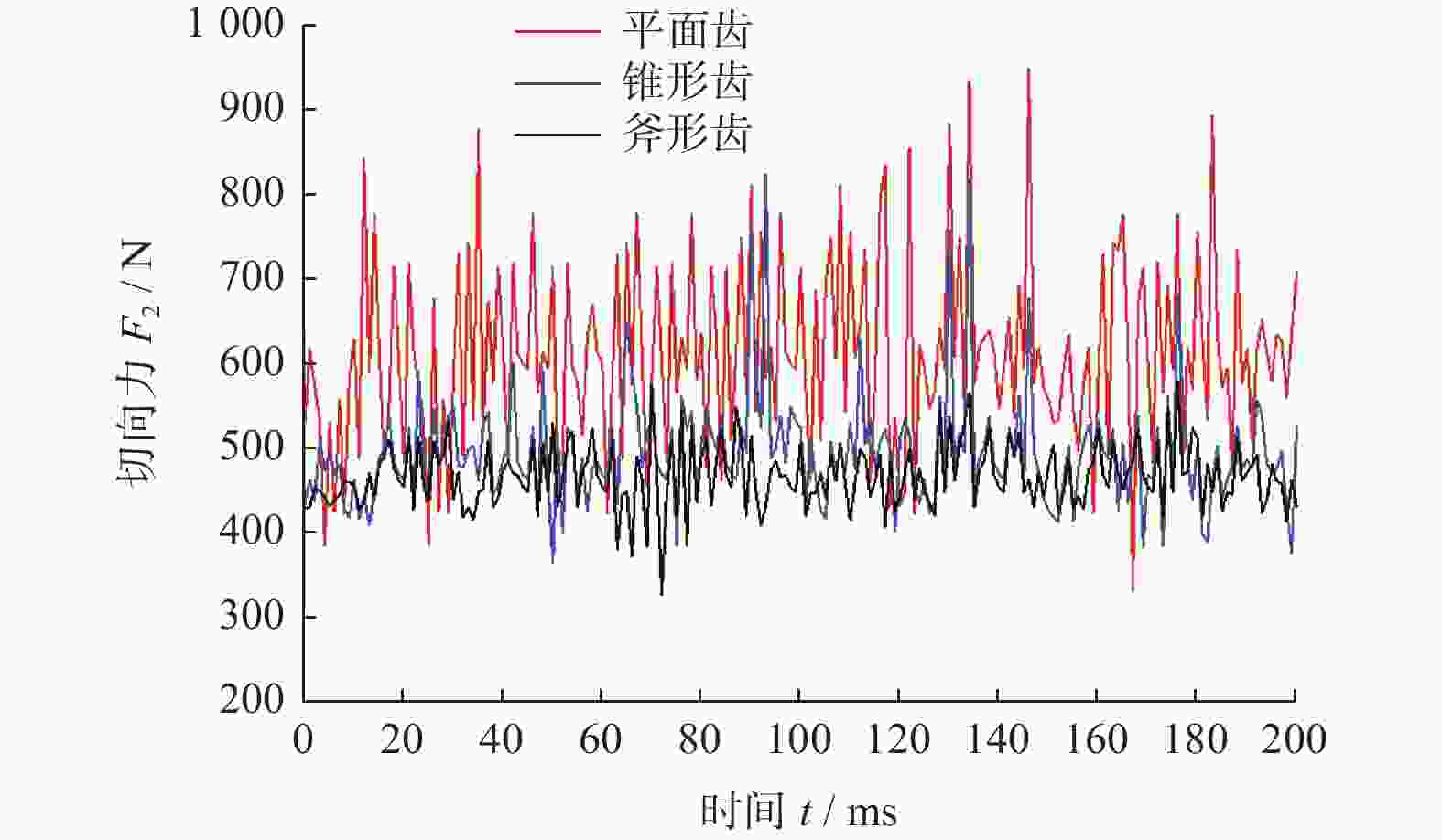

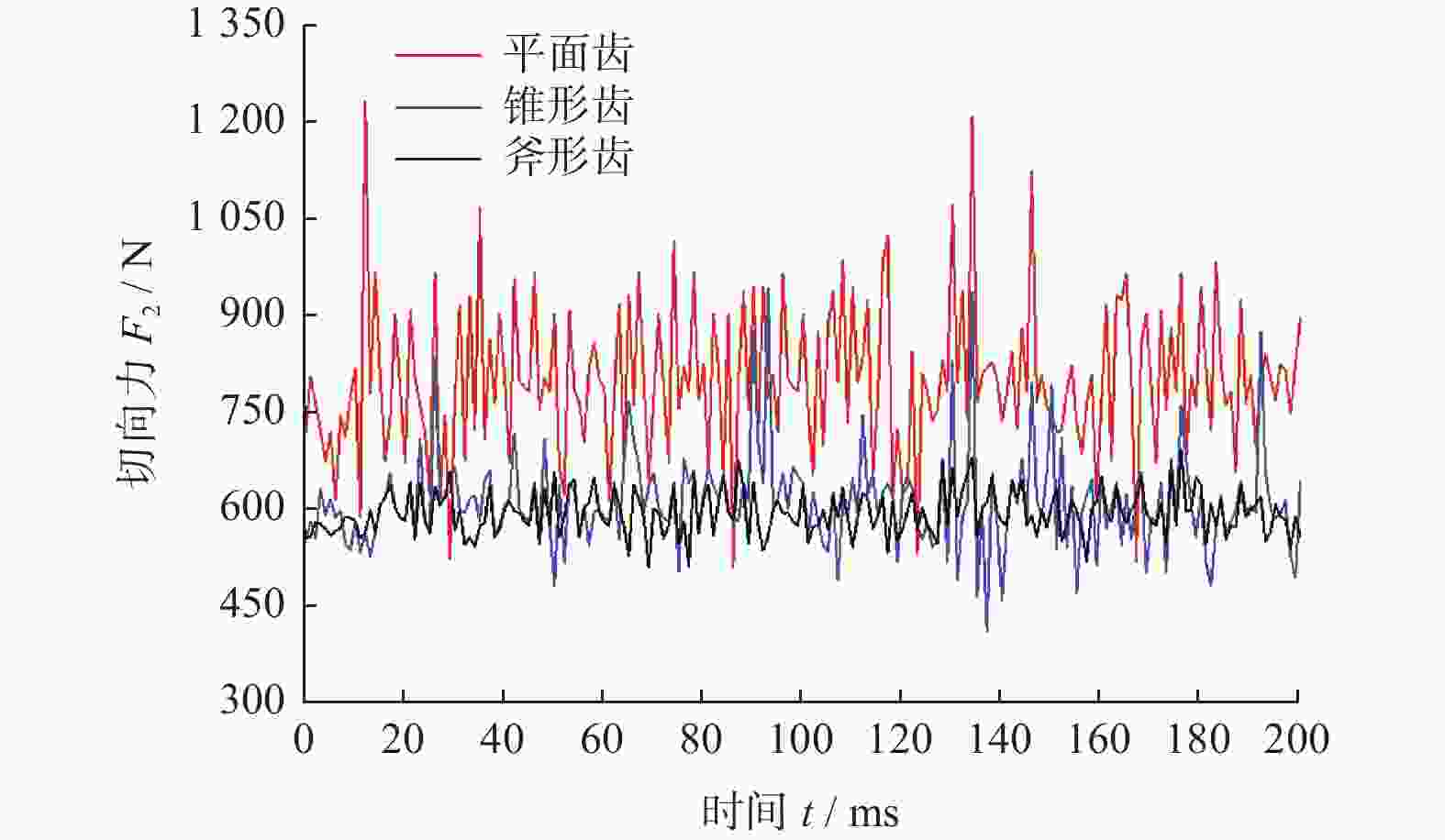

表 1 不同切削齿改变钻压条件下的钻深、切向力

Table 1. Drilling depth and tangential force under different cutting teeth changing weight on bit

钻压

F1 / N切削齿

类型钻进深度

h / mm切向力

平均值 F2 / N切向力

标准差 F3 / N1 000 平面齿 0.937 238.746 60.202 锥形齿 1.648 189.587 51.262 斧形齿 1.765 173.348 32.076 1 500 平面齿 1.475 406.124 75.32 锥形齿 2.176 337.641 56.645 斧形齿 2.497 312.258 32.060 2 000 平面齿 1.873 613.237 110.166 锥形齿 2.497 497.215 66.182 斧形齿 2.719 468.768 38.237 2 500 平面齿 2.311 801.129 115.548 锥形齿 2.893 612.786 75.649 斧形齿 3.312 594.995 34.839 表 2 刀具和岩石材料参数

Table 2. Tool and rock material parameters

材料类别 密度 ρ /(g·cm−3) 弹性模量 E / GPa 泊松比 μ 热导率 k /(J·m−1·S−1·℃−1) 比热容 J /(kg·℃) 抗拉强度 Rm / MPa PDC 3.485 860 0.07 543.0 790 砾岩 2.500 20 0.30 3.5 800 5.3 -

[1] SNEDDON M V, HALL D R. Polycrystalline diamond: Manufacture, wear mechanisms, and implications for bit design [J]. Journal of Petroleum Technology,1988(12):1593-1601. [2] 杨丽, 陈康民. PDC钻头的应用现状与发展前景[J]. 石油机械, 2007, 35(12): 70-72.YANG Li, CHEN Kangmin. Application status and development prospect of PDC bit [J]. Petroleum Machinery, 2007, 35 (12): 70-72. [3] 李国欣, 覃建华, 鲜成钢, 等. 致密砾岩油田高效开发理论认识、关键技术与实践−以准噶尔盆地玛湖油田为例 [J]. 石油勘探与开发,2020,47(6):1185-1197. doi: 10.11698/PED.2020.06.11LI Guoxin, QIN Jianhua, XIAN Chenggang, et al. Theoretical understandings, key technologies and practices of tight conglomerate oilfield efficient development: A case study of the Mahu oilfield, Junggar Basin, NW China [J]. Petroleum Exploration and Development,2020,47(6):1185-1197. doi: 10.11698/PED.2020.06.11 [4] RAYMOND D W. PDC bits demonstrate benefit over conventional hard-rock drill bits [J]. Geothermal Resources Council Transaction,2001,25(8):125-132. [5] RODRIGUEZ C S, MONTEJO C. Enhancements in PDC bit design and drilling optimization tackle hard conglomerate rock drilling in northern mexico[C]// SPE Annual Technical Conference and Exhibition. San Antonio: Society of Petroleum Engineers, 2006: 1-10. [6] HARELAND G, NYGAARD R, YAN W, et al. Cutting efficiency of a single PDC cutter on hard rock [J]. Journal ot Canadian Petroleum Technology,2009,48(6):60-65. doi: 10.2118/09-06-60 [7] 祝小林, 杨灿, 张鸥, 等. 新型PDC钻头砾岩破岩技术及应用 [J]. 石油机械, 2019, 47(6): 28-32.ZHU Xiaolin, YANG Can, ZHANG Ou, et al. Conglomerate rock breaking technology with new PDC cutter and its application [J]. Petroleum Machinery, 2019, 47 (6): 28-32. [8] 刘和兴, 罗云旭, 刘伟吉, 等. 异形PDC齿切削破碎非均质花岗岩机理研究[J]. 石油机械, 2022, 50(4): 22-31.LIU Hexing, LUO Yunxu, LIU Weiji, et al. Rock-breaking mechanism of special-shaped PDC cutter in heterogeneous granite [J] Petroleum Machinery, 2022, 50 (4): 22-31. [9] 邹德永, 任尊亮, 陈雅辉, 等. 硅质白云岩PDC钻头齿型优选实验研究[J]. 钻采工艺, 2021, 44(6): 19-24.ZOU Deyong, REN Zunliang, CHEN Yahui, et al. Experimental study on PDC cutter profile optimization for siliceous dolomite [J]. Drilling and Production Technology, 2021, 44 (6): 19-24. [10] 黄鹏. PDC钻头切削齿在砾岩层中磨损规律研究 [D]. 武汉: 长江大学, 2021.HUANG Peng. Research on the wear law of PDC bit cutting teeth in conglomerate layer [D] WU Han: Changjiang University, 2021. [11] 楼一珊, 金业权. 岩石力学与石油工程[M]. 北京: 石油工业出版社, 2006.LOU Yishan, JIN Yequan. Rock Mechanics and Petroleum Engineering [M]. Beijing: Petroleum Industry Press, 2006 [12] 蔡美峰, 何满潮, 刘东燕. 岩石力学与工程 [M]. 北京: 科学出版社, 2002.CAI Meifeng, HE Manchao, LIU Dongyan. Rock mechanics and engineering [M]. Beijing: Science Press, 2002. [13] 况雨春, 彭亚洲, 张雨婷. PDC全钻头破岩数值模拟及试验研究 [J]. 石油机械,2015,43(9):10-13. doi: 10.16082/j.cnki.issn.1001-4578.2015.09.003KUANG Yuchun, PENG Yazhou, ZHANG Yuting. Numerical simulation and experiment on rock breaking of PDC bits [J]. Petroleum Machinery,2015,43(9):10-13. doi: 10.16082/j.cnki.issn.1001-4578.2015.09.003 [14] 严成森. 屋脊齿PDC钻头破岩机理与设计研究 [D]. 四川: 西南石油大学, 2018.YAN Chengsen. Research on rock breaking mechanism and design of roof tooth PDC bit [D]. SI Chuan: Southwest Petroleum University, 2018. -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS