Design and optimization of ferric chloride and oxalic acid based slurry to chemically mechanically polish stainless steel

-

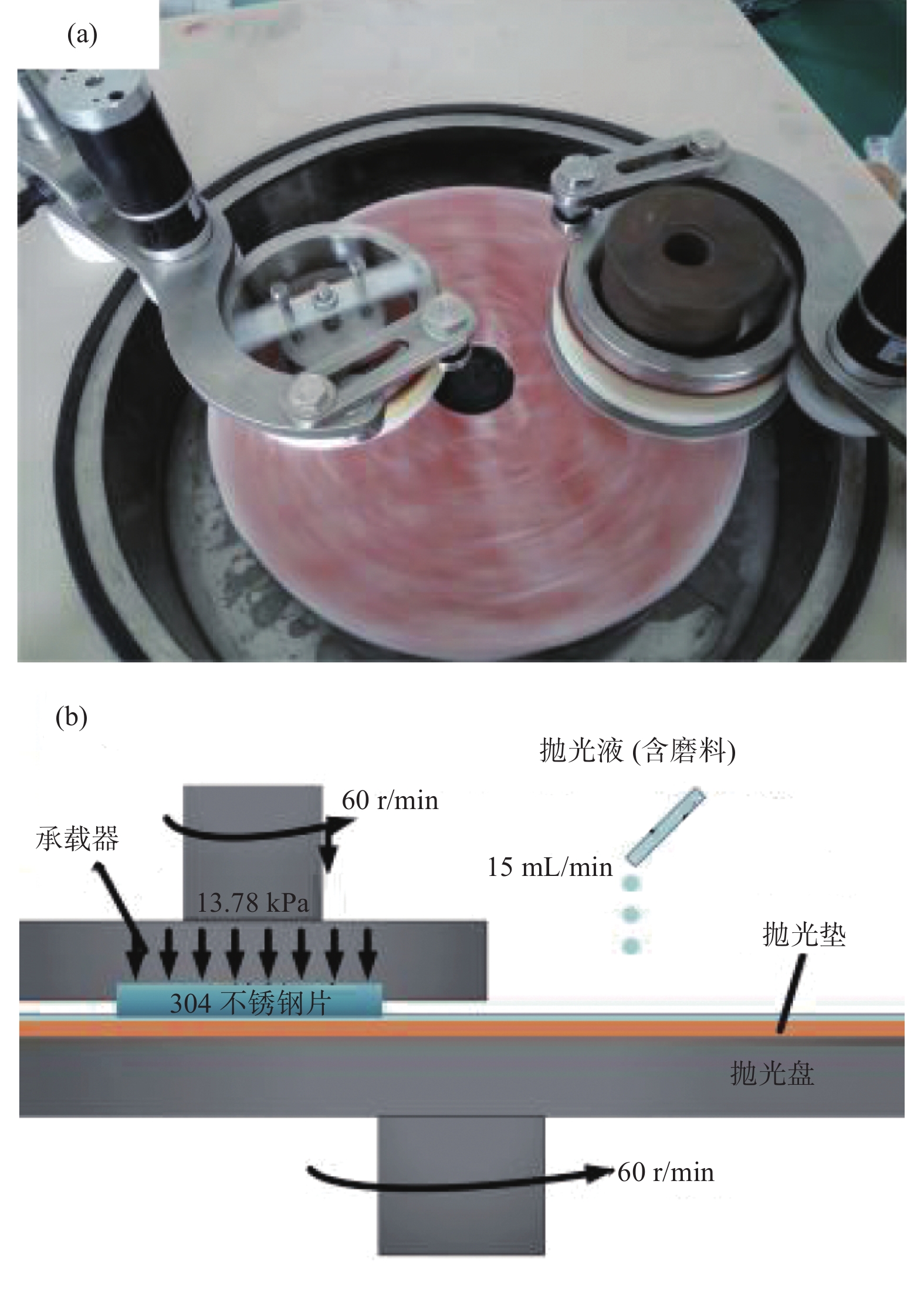

摘要: 为提高柔性显示衬底不锈钢箔片化学机械抛光加工效率,研制一种三氯化铁-草酸型抛光液并用于304不锈钢衬底的化学机械抛光加工过程。设计正交优化试验,确定磨粒粒径、磨料含量、草酸含量和三氯化铁含量对材料去除率和表面粗糙度(Sa)的影响显著性顺序,并重点探究三氯化铁和草酸对材料去除率的影响规律。利用优化后的抛光液精抛304不锈钢,其材料去除率高于560 nm/min,抛光30 min后Sa低于8 nm。相比现有抛光液的材料去除效率(226.56 nm/min),新抛光液的加工效率提升超过1倍。Abstract: To enhance the chemical mechanical polishing (CMP) efficiency of flexible display substrates, a polishing slurry based on ferric chloride and oxalic acid was proposed for polishing 304 stainless steel substrates. An orthogonal optimization test was designed to determine the significance order of the influence of abrasive size, abrasive content, oxalic acid content and ferric chloride content on the material removal rate (MRR) and surface roughness (surface arithmetical mean height of area, Sa). The aim was to investigate the effects of ferric chloride and oxalic acid on MRR. An optimized polishing slurry capable of achieving an MRR of over 560 nm/min and a Sa as low as 8 nm after 30 min was obtain. Compared with the conventional polishing slurry, whose MRR is 226.56 nm/min, the novel slurry has doubled its polishing efficiency or more.

-

表 1 三氯化铁-草酸型抛光液正交试验

Table 1. Orthogonal test for ferric chloride and oxalic acid type of polishing slurry

水平 因素 a b c d e f

粒

磨料质

分散剂

草酸质

三氯化铁

活性剂

径

量分数

质量分数

量分数

质量分数

质量分数d

/ μmwg

/ %wd

/ %wo

/ %wf

/ %wa

/ %1 0.5 0.8 0.4 0.4 2 0.04 2 7.0 4.0 1.2 0.8 6 0.20 3 14.0 7.2 2.0 1.2 10 0.40 4 28.0 9.6 2.8 1.6 14 0.80 表 2 三氯化铁-草酸型抛光液组分优化试验数据表

Table 2. Experimental data for ferric chloride and oxalic acid type of polishing slurry optimization

序号 a b c d e f DMRR

nm/minSa

nm1 0.5 0.8 0.4 0.4 2 0.04 325.3 13 2 0.5 4.0 1.2 0.8 6 0.20 558.6 11 3 0.5 7.2 2.0 1.2 10 0.40 502.3 8 4 0.5 9.6 2.8 1.6 14 0.80 430.2 9 5 7.0 0.8 0.4 0.8 6 0.40 495.2 12 6 7.0 4.0 1.2 0.4 2 0.80 486.2 29 7 7.0 7.2 2.0 1.6 14 0.04 509.5 21 8 7.0 9.6 2.8 1.2 10 0.20 533.6 19 9 14.0 0.8 1.2 1.2 14 0.4 503.5 19 10 14.0 4.0 0.4 1.6 10 0.20 595.6 17 11 14.0 7.2 2.8 0.4 6 0.04 605.6 36 12 14.0 9.6 2.0 0.8 2 0.80 560.7 23 13 28.0 0.8 1.2 1.6 10 0.40 588.3 29 14 28.0 4.0 0.4 1.2 14 0.80 624.3 27 15 28.0 7.2 2.8 0.8 2 0.04 617.4 36 16 28.0 9.6 2.0 0.4 6 0.20 674.4 23 17 0.5 0.8 2.8 0.4 14 0.20 402.7 13 18 0.5 4.0 2.0 0.8 10 0.04 550.3 11 19 0.5 7.2 1.2 1.2 6 0.80 502.4 8 20 0.5 9.6 0.4 1.6 2 0.40 389.1 9 21 7.0 0.8 2.8 0.8 10 0.80 502.3 12 22 7.0 4.0 2.0 0.4 14 0.40 548.7 29 23 7.0 7.2 1.2 1.6 2 0.20 483.7 21 24 7.0 9.6 0.4 1.2 6 0.04 518.6 19 25 14.0 0.8 2.0 1.2 2 0.20 520.7 19 26 14.0 4.0 2.8 1.6 6 0.04 641.3 17 27 14.0 7.2 0.4 0.4 10 0.80 537.8 36 28 14.0 9.6 1.2 0.8 14 0.40 565.6 23 29 28.0 0.8 2.0 1.6 6 0.80 563.4 29 30 28.0 4.0 2.8 1.2 2 0.40 576.8 27 31 28.0 7.2 0.4 0.8 14 0.20 551.3 36 32 28.0 9.6 1.2 0.4 10 0.04 541.7 23 表 3 抛光液各组分对MRR的影响显著性分析

Table 3. Significance analysis for effect of each component of polishing slurry on MRR

因素 自由度 离均差平方和 均方和 F Pr > F a 3 259 966.862 5 86 655.621 192.93 <0.000 1 b 3 88 715.559 4 29 571.853 65.84 <0.000 1 c 3 30 639.930 0 10 213.310 22.74 <0.000 1 d 3 15 975.215 5 5 325.072 11.86 <0.000 1 e 3 76 268.718 9 25 422.906 56.60 <0.000 1 f 3 3 389.954 0 1 129.985 2.52 0.064 5 表 4 抛光液各组分对Sa的影响显著性分析

Table 4. Significance analysis for effect of each component of polishing slurry on Sa

因素 自由度 离均差平方和 均方和 F Pr > F a 3 0.004 404 00 0.001 468 00 68.44 <0.000 1 b 3 0.000 759 00 0.000 253 00 11.80 <0.000 1 c 3 0.000 013 50 0.000 004 50 0.21 0.889 3 d 3 0.000 711 00 0.000 237 00 11.05 <0.000 1 e 3 0.000 181 50 0.000 0605 0 2.82 0.044 4 f 3 0.000 073 50 0.000 0245 0 1.14 0.337 4 -

[1] ERITT M, MAY C, LEO K, et al. OLED manufacturing for large area lighting applications [J]. Thin Solid Films,2010,518(11):3042-3045. doi: 10.1016/j.tsf.2009.09.188 [2] GUSTAFSSON G, CAO Y, TREACY G M, et al. Flexible light-emitting diodes made from soluble conducting polymers [J]. Nature,1992,357(6378):477-479. doi: 10.1038/357477a0 [3] LEWIS J S, WEAVER M S. Thin-film permeation-barrier technology for flexible organic light-emitting devices [J]. IEEE Journal of Selected Topics in Quantum Electronics,2004,10(1):45-57. doi: 10.1109/JSTQE.2004.824072 [4] YUAN Y Y, HAN S, GROZEA D, et al. Fullerene-organic nanocomposite: A flexible material platform for organic light-emitting diodes [J]. Applied Physics Letters,2006,88(9):093503. doi: 10.1063/1.2180876 [5] CHWANG A B, ROTHMAN M A, MAO S Y, et al. Thin film encapsulated flexible organic electroluminescent displays [J]. Applied Physics Letters,2003,83(3):413-415. doi: 10.1063/1.1594284 [6] HANANDA T, NEGISHI T, SHIROISHI I, et al. Plastic substrate with gas barrier layer and transparent conductive oxide thin film for flexible displays [J]. Thin Solid Films,2010,518(11):3089-3092. doi: 10.1016/j.tsf.2009.09.166 [7] 杨利营, 印寿根, 华玉林, 等. 柔性显示器件的衬底材料及封装技术 [J]. 功能材料,2006(1):10-13.YANG Liying, YIN Shougen, HUA Yulin, et al. Flexible substrates and encapsulation methods for flexible organic light emitting devices [J]. Jorunal of Functional Materials,2006(1):10-13. [8] 冯魏良, 黄培. 柔性显示衬底的研究及进展 [J]. 液晶与显示,2012,27(5):599-607. doi: 10.3788/YJYXS20122705.0599FENG Weiliang, HUANG Pei. Advances in flexible displays substrates [J]. Chinese Journal of Liquid Crystals and Displays,2012,27(5):599-607. doi: 10.3788/YJYXS20122705.0599 [9] AUCH M D J, SOO O K, EWALD G, et al. Ultrathin glass for flexible OLED application [J]. Thin solid films,2002,417(1):47-50. [10] 廖显杰. 柔性显示的“面子”和“里子”−谈基板材料的发展现状与趋势 [J]. 中国数字电视,2007(Z1):84-87.LIAO Xianjie. The "surface" and "inside" of flexible display: The development status and trend of substrate materials [J]. China Digital TV,2007(Z1):84-87. [11] 刘海旭, 武庆东, 曹潇俊, 等. 基于响应曲面法的304不锈钢化学机械抛光工艺参数优化 [J]. 金刚石与磨料磨具工程,2021,41(2):89-95.LIU Haixu, WU Qingdong, CAO Xiaojun, et al. Prediction and optimization of process parameters in chemical mechanical polishing for 304 stainless steel based on response surface methodology [J]. Diamond & Abrasives Engineering,2021,41(2):89-95. [12] 李庆, 陈绍坤, 彭亚男, 等. 304不锈钢化学机械抛光工艺参数研究 [J]. 金刚石与磨料磨具工程,2016,36(5):21-25.LI Qing, CHEN Shaokun, PENG Yanan, et al. Chemical mechanical polishing process parameters of 304 stainless steel [J]. Diamond & Abrasives Engineering,2016,36(5):21-25. [13] 秦洪权, 王永胜, 李庆, 等. 化学机械抛光超薄SUS304不锈钢抛光液研究 [J]. 金刚石与磨料磨具工程,2016,36(6):25-28+34.QIN Hongquan, WANG Yongsheng, LI Qing, et al. Polishing slurry of chemical mechanical polishing SUS304 ultrathin stainless steel sheet [J]. Diamond & Abrasives Engineering,2016,36(6):25-28+34. [14] HU X, SONG Z, LIU W, et al. Chemical mechanical polishing of stainless steel foil as flexible substrate [J]. Applied Surface Science,2012,258(15):5798-5802. doi: 10.1016/j.apsusc.2012.02.100 [15] 杨向东, 魏昕, 谢小柱, 等. 基于化学机械抛光过程的超薄不锈钢基板表面特性分析 [J]. 润滑与密封,2015,40(4):45-48+53.YANG Xiangdong, WEI Xin, XIE Xiaozhu, et al. Analysis of surface characteristics of ultra-thin stainless steel substrate based on chemical mechanical polishing process [J]. Lubrication Engineering,2015,40(4):45-48+53. [16] 刘振辉, 陈绍坤, 彭亚男, 等. 化学机械抛光304不锈钢用抛光液成分研究 [J]. 金刚石与磨料磨具工程,2018,38(2):78-81+88.LIU Zhenhui, CHEN Shaokun, PENG Yanan, et al. Compositions of slurry used in chemical-mechanical polishing 304 stainless steel [J]. Diamond & Abrasives Engineering,2018,38(2):78-81+88. [17] 张仁杰, 张振宇, 李玉彪, 等. 304不锈钢绿色化学机械抛光 [J]. 表面技术,2022,51(5):325-335.ZHANG Renjie, ZHANG Zhenyu, LI Yubiao, et al. Green chemical mechanical polishing of 304 stainless steel [J]. Surface Technology,2022,51(5):325-335. [18] 崔洪刚, 汪永超, 唐浩. 不锈钢CMP抛光液的研制 [J]. 机械设计与制造,2018(1):73-75. doi: 10.19356/j.cnki.1001-3997.2018.01.021 [19] 王浩, 陈国美, 倪自丰, 等. 1, 2, 4–三氮唑和苯并三氮唑对316L不锈钢化学机械抛光的影响 [J]. 金刚石与磨料磨具工程,2021,41(1):83-88.WANG Hao, CHEN Guomei, NI Zifeng, et al. Effect of 1, 2, 4 - triazole and benzotriazole on chemical-mechanical polishing of 316L stainless steel [J]. Diamond & Abrasives Engineering,2021,41(1):83-88. [20] 陈佳鹏, 陈绍坤, 李庆, 等. 用碱性抛光液化学机械抛光304不锈钢片研究 [J]. 金刚石与磨料磨具工程,2016,36(2):6-9+23.CHEN Jiapeng, CHEN Shaokun, LI Qing, et al. Study on chemical mechanical polishing 304 stainless steel sheet based on alkaline polishing slurry [J]. Diamond & Abrasives Engineering,2016,36(2):6-9+23. -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS