Experimental study on rock cutting characteristics of granite broken by impregnated diamond bit

-

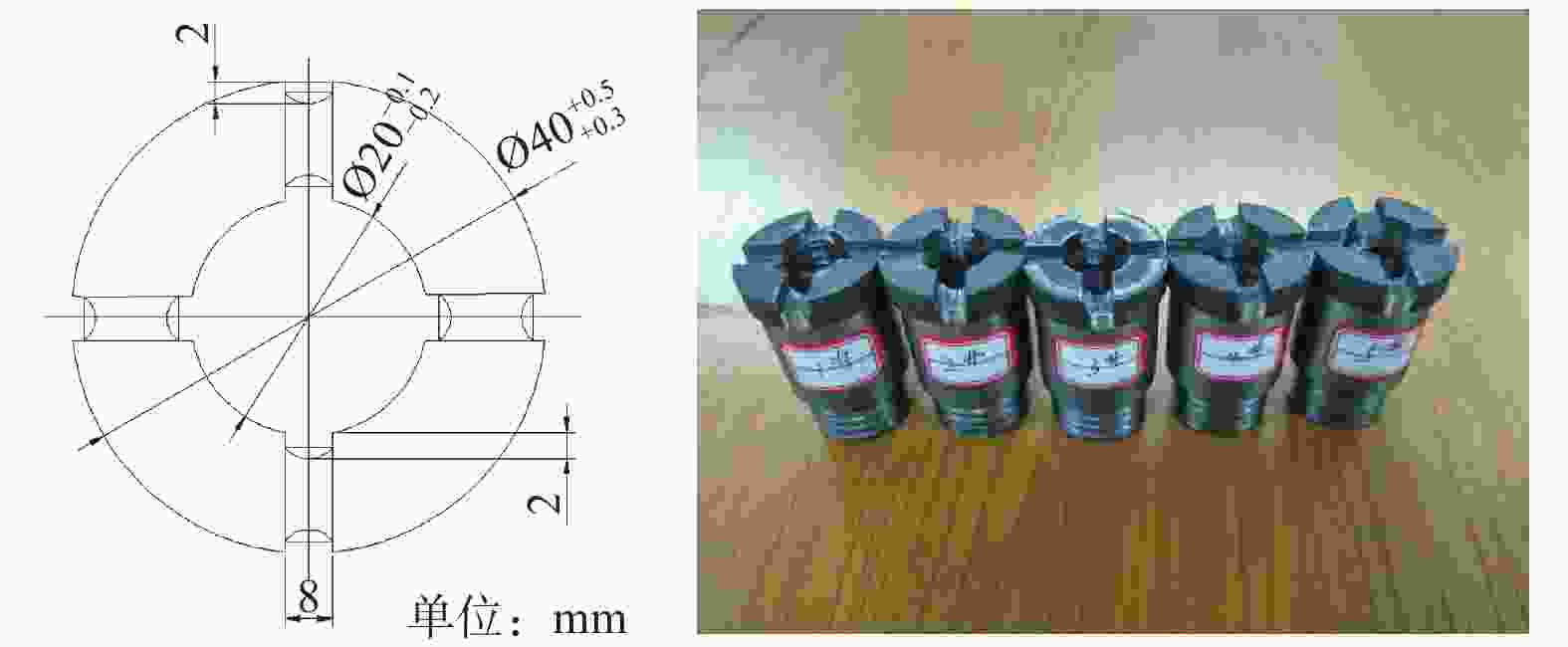

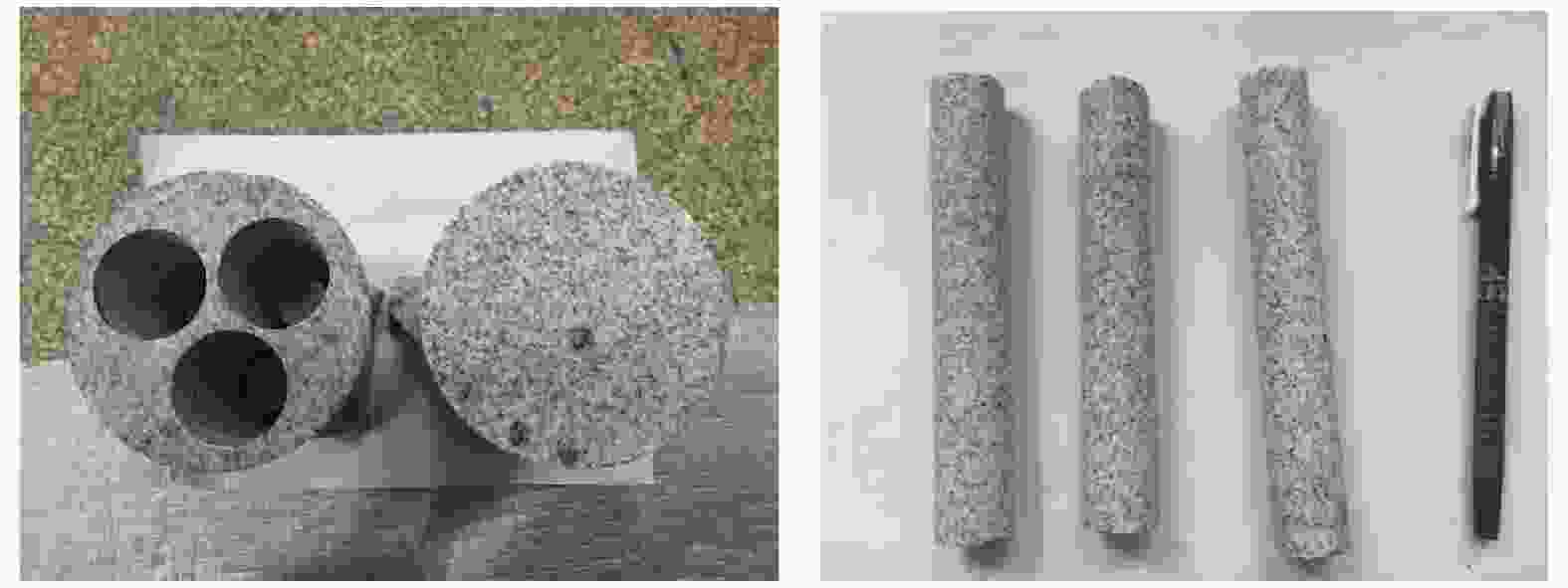

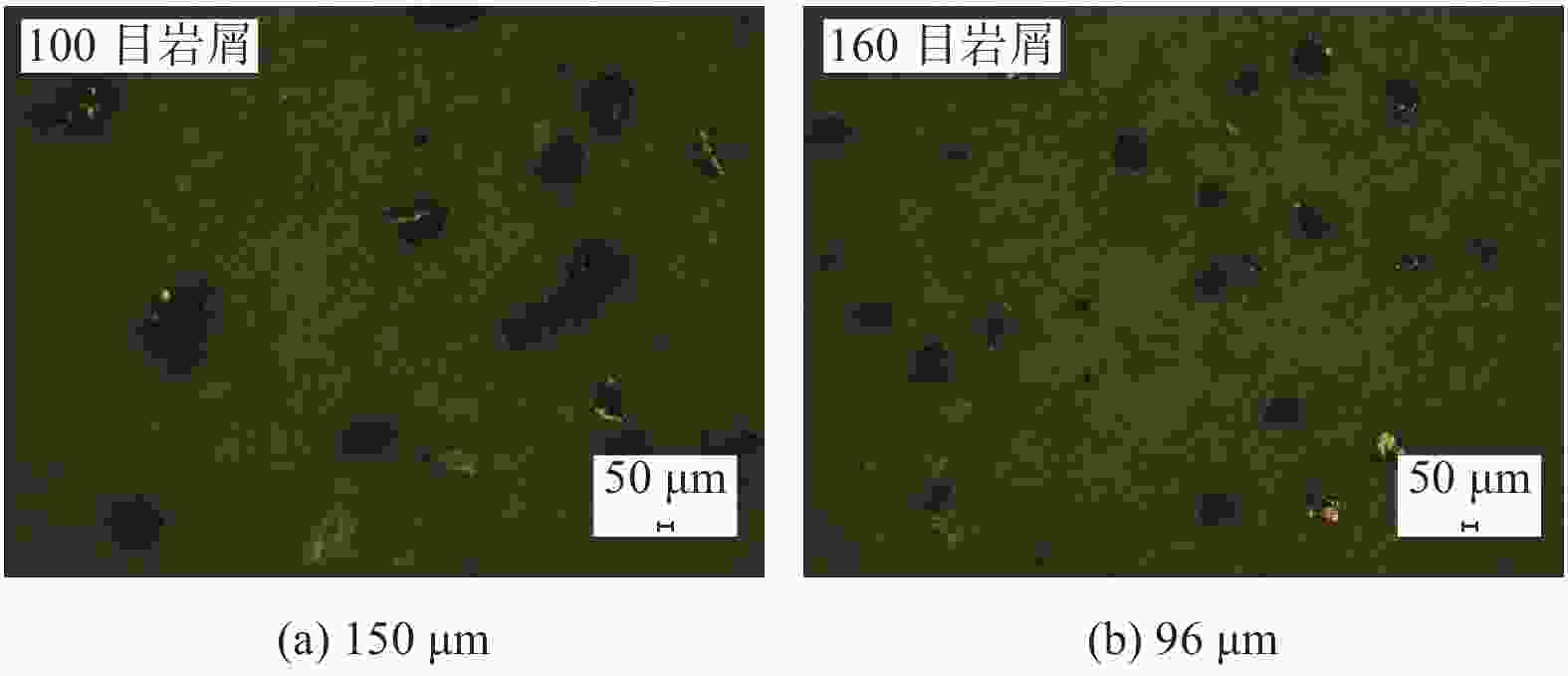

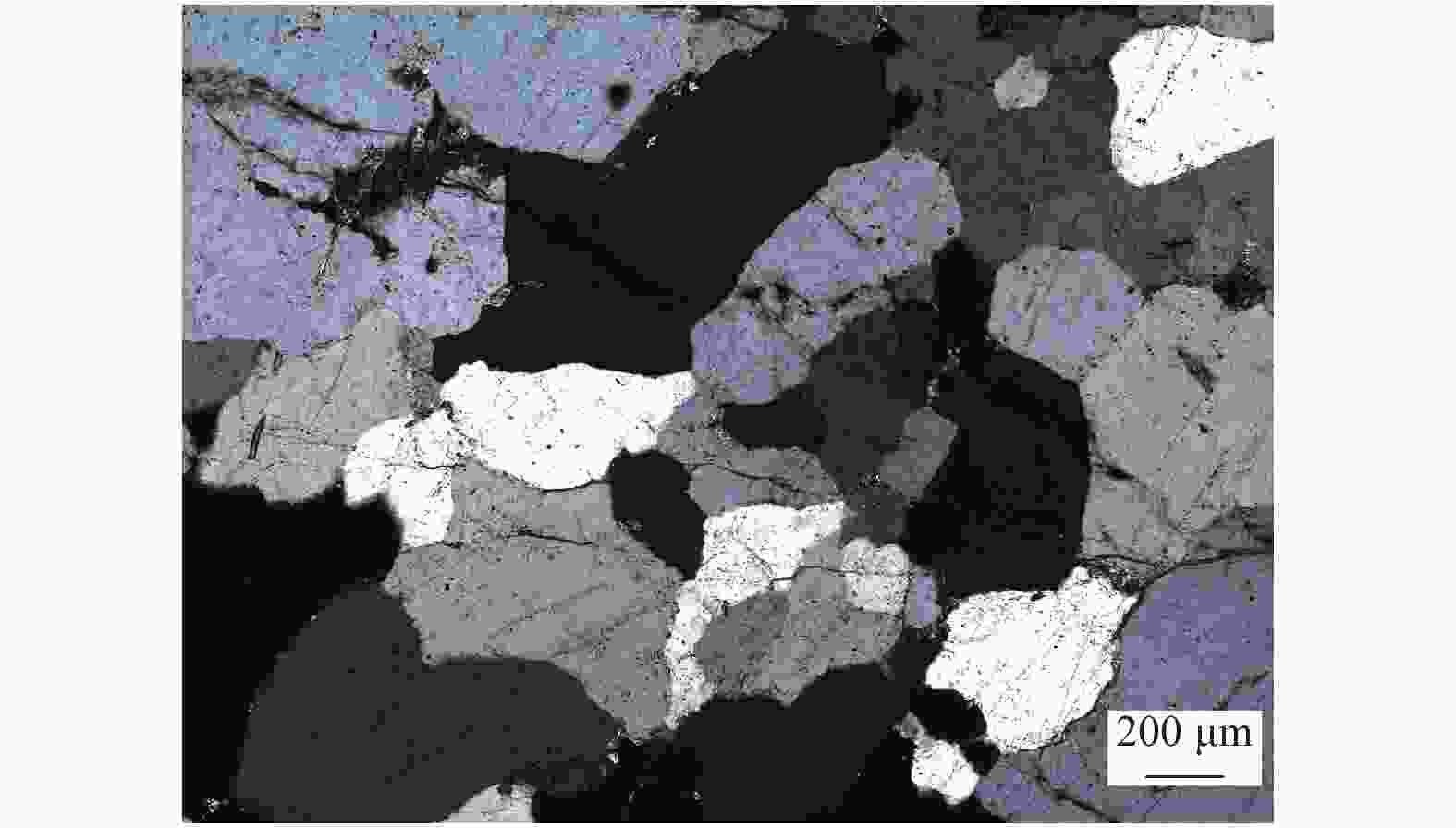

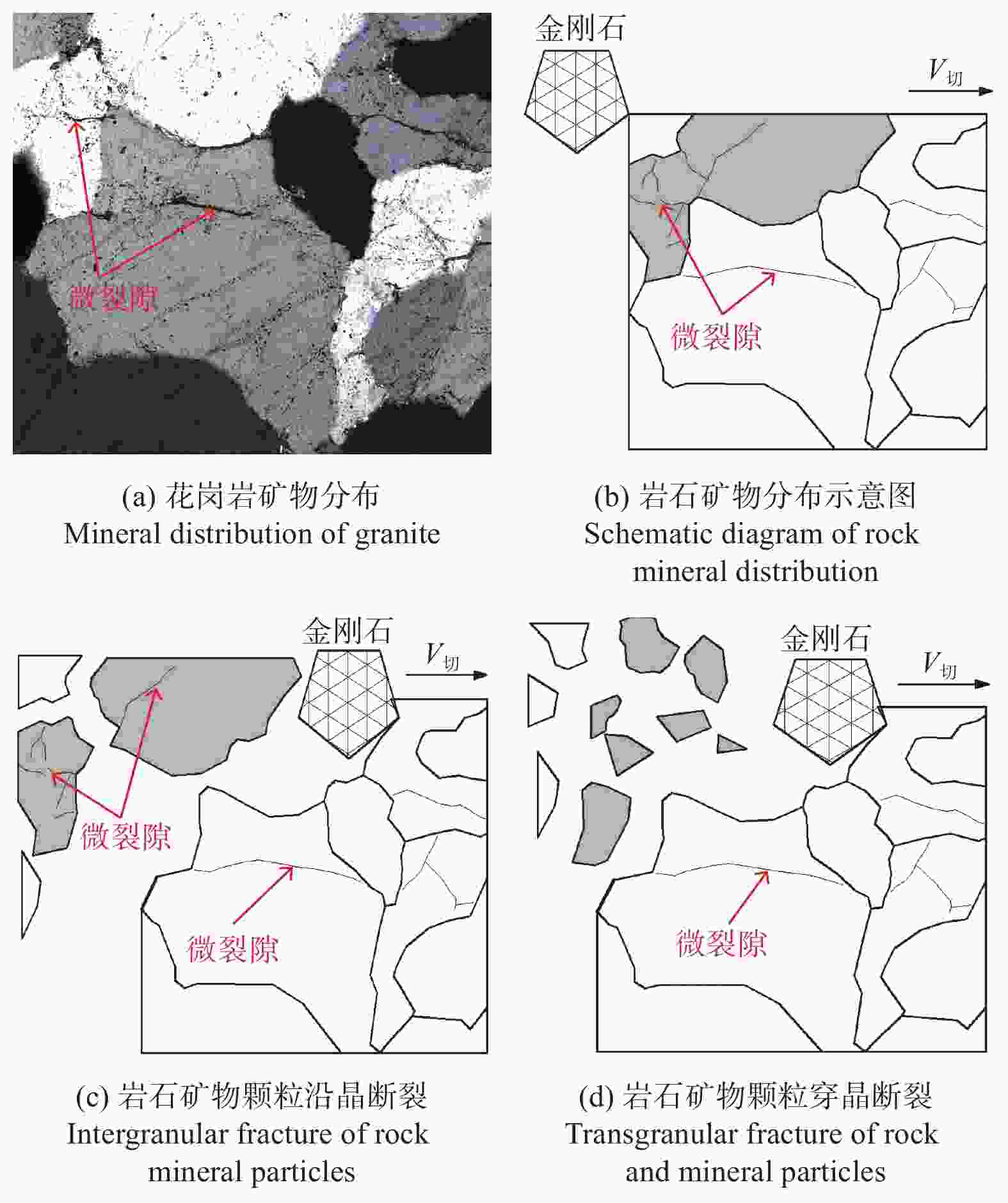

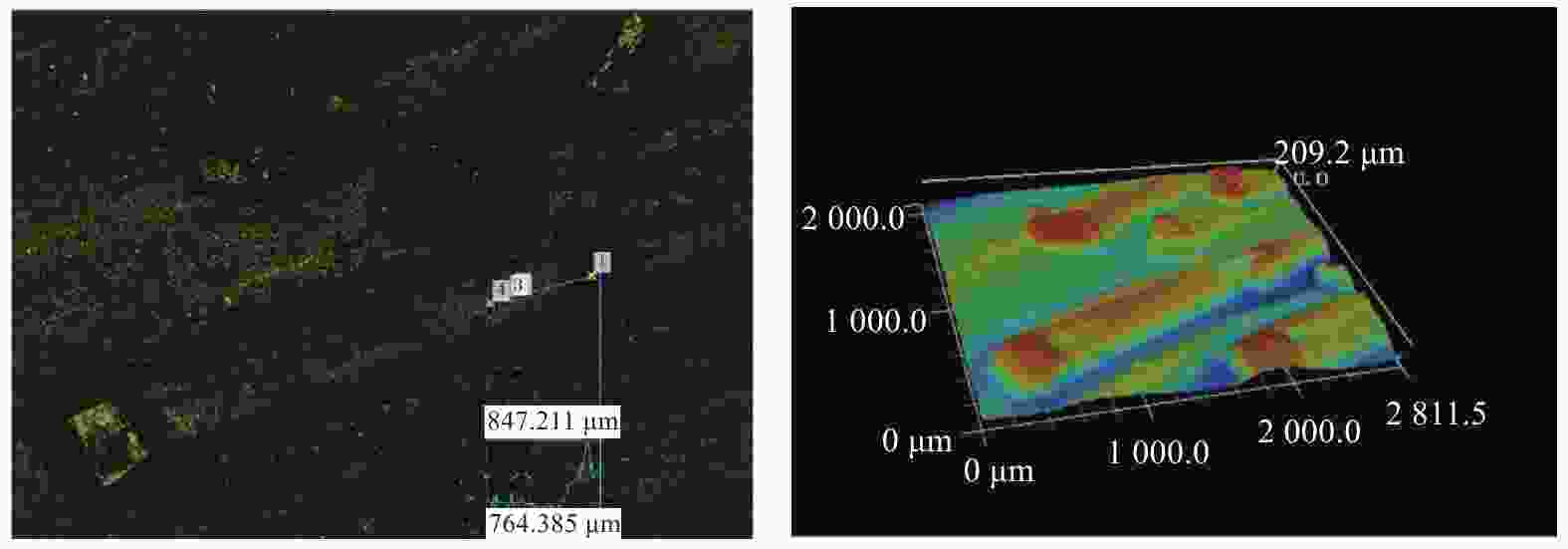

摘要: 岩屑的特征参数是影响其环空上返的一个重要因素。为研究孕镶金刚石钻头钻进花岗岩所产生的岩屑特性,开展室内微钻试验。研究发现碎岩产生的岩屑在一定范围内呈单峰值分布,且岩屑粒度分布范围与钻压、转速等钻进参数有关;在一定程度上岩屑峰值粒径随着钻压的增大而变大,随着转速的增大而变小。进一步显微观察岩屑形貌特征,发现岩屑颗粒基本小于岩石原矿物颗粒尺寸,且岩屑颗粒多呈单一矿物成分,较少有多种矿物相互混杂的岩屑颗粒;显微观察岩屑与岩石表面形貌特征,发现孕镶金刚石钻头钻进花岗岩时以体积破碎的方式为主、塑形微切削方式为辅。Abstract: The characteristics of rock cuttings are important factors affecting their annulus upward return. The indoor micro drilling experiment was carried out to study the characteristics of rock cuttings produced by impregnated diamond bit breaking granite. It is found that the rock cuttings produced by broken rock show single peak distribution in a certain range, and that the distribution is related to drilling parameters such as WOB and rotating speed. To some extent, the peak particle size of cuttings increases with the increase of WOB and decreases with the increase of rotating speed. Further microscopic observation on the morphological characteristics of rock cuttings shows that the particle size of rock cuttings is basically smaller than that of original minerals, and that most of the rock cuttings are of single mineral composition. Further observation on the morphology characteristics of rock cuttings and rock surface shows that the impregnated diamond bit drilling granite is mainly in the form of volume crushing, supplemented by plastic micro cutting.

-

Key words:

- impregnated diamond bit /

- granite /

- cutting characteristics /

- drilling parameters /

- laboratory test

-

表 1 花岗岩中各矿物成分含量

Table 1. Contents of mineral components in granite

矿物成分 质量分数 w / % 正长石 60 斜长石 15 石英 15 黑云母 5 其他 5 表 2 理论范围值与实际岩屑粒径对比

Table 2. Comparison between theoretical range and actual range of rock debris particle size

对比类型 岩屑粒径 dg / mm 克取深度范围 0.034~0.051 岩屑粒径范围 0.040~0.250 岩屑粒径峰值 0.075 岩屑含量比例 R / % 粒径小于克取深度 粒径大于克取深度 18.67 81.33 -

[1] 夏环宇, 翟应虎, 王磊, 等. 考虑粒径分布的深水环空岩屑浓度研究及应用 [J]. 科学技术与工程,2011,35:8876-8881. doi: 10.3969/j.issn.1671-1815.2011.35.048XIA Huanyu, ZHAI Yinghu, WANG Lei, et al. Study and application of cuttings concentration in deep water annulus considering particle size distribution [J]. Science Technology and Engineering,2011,35:8876-8881. doi: 10.3969/j.issn.1671-1815.2011.35.048 [2] 易先中, 王利成, 魏慧明, 等. 钻井岩屑粒径分布规律的研究 [J]. 石油机械,2007,35(12):1-4. doi: 10.3969/j.issn.1001-4578.2007.12.001YI Xianzhong, WANG Licheng, WEI Huiming, et al. Study on particle size distribution of drilling cuttings [J]. China Petroleum Machinery,2007,35(12):1-4. doi: 10.3969/j.issn.1001-4578.2007.12.001 [3] 刘海声, 汪洪民, 刘鹏, 等. 西藏安多县多才玛矿区强研磨性地层孕镶金刚石使用效果分析 [J]. 地质与勘探,2019,55(6):1473-1483.LIU Haisheng, WANG Hongmin, LIU Peng, et al. Analysis on the application effect of impregnated diamond in strong abrasive strata in Duocaima Mining Area, Anduo County, Tibet [J]. Geology and Exploration,2019,55(6):1473-1483. [4] 王佳亮, 张绍和. 针对坚硬致密弱研磨性岩层的金刚石钻头研究进展 [J]. 金刚石磨料磨具工程,2016,36(2):78-88.WANG Jialiang, ZHANG Shaohe. Progress and development on impregnated diamond bit for ultrahard compact and weak-abrasion rock formation [J]. Diamond & Abrasive Engineering,2016,36(2):78-88. [5] 李英杰. 钻进参数对孕镶金刚石钻头磨损及钻速的影响 [J]. 煤田地质与勘探, 1993(6): 65-66.LI Yingjie, Effect of drilling parameters on wear and penetration rate of impregnated diamond bit [J]. Coal Geology & Exploration, 1993(6): 65-66. [6] 袁军, 邹德永, 钟洪娇, 等. 适用于研磨性硬地层的新型孕镶金刚石钻头优化设计试验研究 [J]. 科学技术与工程, 2016, 16(4): 16-21.YUAN Jun, ZOU Deyong, ZHONG Hongjiao, et al Experimental study on optimal design of new impregnated diamond bit suitable for abrasive hard formation [J]. Science Technology and Engineering, 2016, 16 (4): 16-21. [7] 李子杰, 赵洪山, 冯光通, 等. 致密砂岩地层孕镶金刚石参数的试验优选研究 [J]. 钻采工艺,2020,43(5):12-15. doi: 10.3969/J.ISSN.1006-768X.2020.05.04LI Zijie, ZHAO Hongshan, FENG Guangtong, et al. Experimental optimization of impregnated diamond parameters in tight sandstone formation [J]. Drilling & Production Technology,2020,43(5):12-15. doi: 10.3969/J.ISSN.1006-768X.2020.05.04 [8] 赵小军, 康鑫, 潘飞飞, 等. 孕镶金刚石钻头破碎花岗岩岩屑粒径分布研究 [J. 金刚石磨料磨具工程, 2019, 39(1): 84-88ZHAO Xiaojun, KANG Xin, PAN Feifei, et al Study on particle size distribution of granite cuttings broken by impregnated diamond bit [J]. Diamond & Abrasives Engineering, 2019, 39(1): 84-88. [9] 赵如意, 黄辉, 郭桦, 等. 金刚石绳锯切割花岗石过程中岩屑粒度分布研究 [J]. 金刚石磨料磨具工程,2014,34(2):52-56.ZHAO Ruyi, HUANG Hui, GUO Hua, et al. Particle size distribution of swarf in the granite sawing by diamond wire saw [J]. Diamond & Abrasives Engineering,2014,34(2):52-56. [10] 汤凤林, Heckopomhbix B B, 段隆臣, 等. 金刚石钻进岩石破碎过程及其与规程参数关系的研究 [J]. 钻探工程,2021,48(10):43-55.TANG Fenglin, HECKOPOMHBIX B B, DUAN Longchen, et al. Study on rock crushing process of diamond drilling and its relationship with specification parameters [J]. Drilling Engineering,2021,48(10):43-55. [11] 潘秉锁, 史冬梅, 杨凯华. 金刚石粒度对孕镶金刚石钻头性能的影响 [J]. 煤田地质与勘探,2002,30(3):62-64. doi: 10.3969/j.issn.1001-1986.2002.03.020PAN Bingsuo, SHI Dongmei, YANG Kaihua. Effect of diamond particle size on properties of impregnated diamond bit [J]. Coal Geology & Exploration,2002,30(3):62-64. doi: 10.3969/j.issn.1001-1986.2002.03.020 [12] 王传留, 孙友宏, 刘宝昌, 等. 仿生耦合孕镶金刚石钻头的试验及碎岩机理分析 [J]. 中南大学学报(自然科学版),2011,42(5):1321-1325.WANG Chuanliu, SUN Youhong, LIU Baochang, et al. Experiment of bionic coupling impregnated diamond bit and analysis of rock breaking mechanism [J]. Journal of Central South University (Science and Technology),2011,42(5):1321-1325. [13] 赵金昌, 万志军, 李义, 等. 高温高压条件下花岗岩切削破碎试验研究 [J]. 岩石力学与工程学报,2009,28(7):1432-1438. doi: 10.3321/j.issn:1000-6915.2009.07.017ZHAO Jinchang, WAN Zhijun, LI Yi, et al. Experimental study on cutting and crushing of granite under high temperature and high pressure [J]. Chinese Journal of Rock Mechanics and Engineering,2009,28(7):1432-1438. doi: 10.3321/j.issn:1000-6915.2009.07.017 [14] 孙吉伟, 沈立娜, 杨甘生, 等. 孕镶金刚石钻头的局部体积破碎研究 [J]. 煤田地质与勘探,2019,47(5):232-238. doi: 10.3969/j.issn.1001-1986.2019.05.033SUN Jiwei, SHEN Lina, YANG Gansheng, et al. Study on local volume fragmentation of impregnated diamond bit [J]. Coal Geology & Exploration,2019,47(5):232-238. doi: 10.3969/j.issn.1001-1986.2019.05.033 -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS