Simulation of reinforced concrete cutting based on SPH method

-

摘要: 钢筋混凝土材料目前已得到广泛应用,但其加工切削过程十分复杂。为解决常规有限元模拟中网格变形尺寸有限的局限性,采用光滑粒子流体动力学(SPH)算法模拟研究金刚石磨粒对钢筋混凝土的切削破碎过程。在数值模拟中,根据金刚石出刃状态将其简化成方形、圆形2种磨粒,并以0.45 mm/ms的速度和0.1 mm的切削深度对钢筋、混凝土和不同组合的钢筋混凝土材料进行表面切削,分析不同情况下的基体碎屑形态特征、切削后基体材料表面形态变化、内部裂纹延伸变化以及磨粒切削面上的应力变化情况。模拟结果表明:SPH方法能够较好地模拟钢筋混凝土在切削过程中的裂纹扩展、碎屑形成和分离;磨粒在切削过程中受到间断性冲击后,会优先破坏混凝土和钢筋材料之间的连接强度,使2种材料逐渐分离,且磨粒以面切削方式进行加工时,相较于点切削方式,能够形成更大的破碎区域。Abstract: Reinforced concrete structure has been widely applied in modern society, while its cutting process is very complicated. To solve the inaccurate problem due to grid deformation in conventional finite element method, smoothed particle hydrodynamics (SPH) particle algorithm was adopted to simulate the cutting and breaking processes of reinforced concrete by diamond abrasive particle. According to their possible protrusion states of diamonds on tools’ working surface, diamonds were simplified as square and circular abrasives respectively. Then, the abrasives performed surface cutting on steel, concrete, and different combinations of reinforced concrete materials at a cutting speed of 0.45 mm/ms and a cutting depth of 0.1 mm. The morphological characteristics of cutting chips, the morphological change of the working pieces surface after cutting, the change of crack extension within the working pieces, as well as the stress change on the cutting surface of two kinds of abrasives were analyzed. The simulation results indicate that the SPH method can simulate the crack propagation, the chip formation and the materials separation during the cutting process. The intermittent impact on abrasives in the cutting process will preferentially destroy the connection between the two materials which can be gradually separated to each other. Besides, in the surface cutting type of square abrasive there can form a larger broken area than that in the point cutting type of circular abrasive.

-

Key words:

- reinforced concrete /

- numerical simulation /

- smoothed particle hydrodynamics /

- diamond /

- cutting process

-

表 1 钢筋的Johnson-Cook模型参数

Table 1. Johnson-Cook model parameters of steel

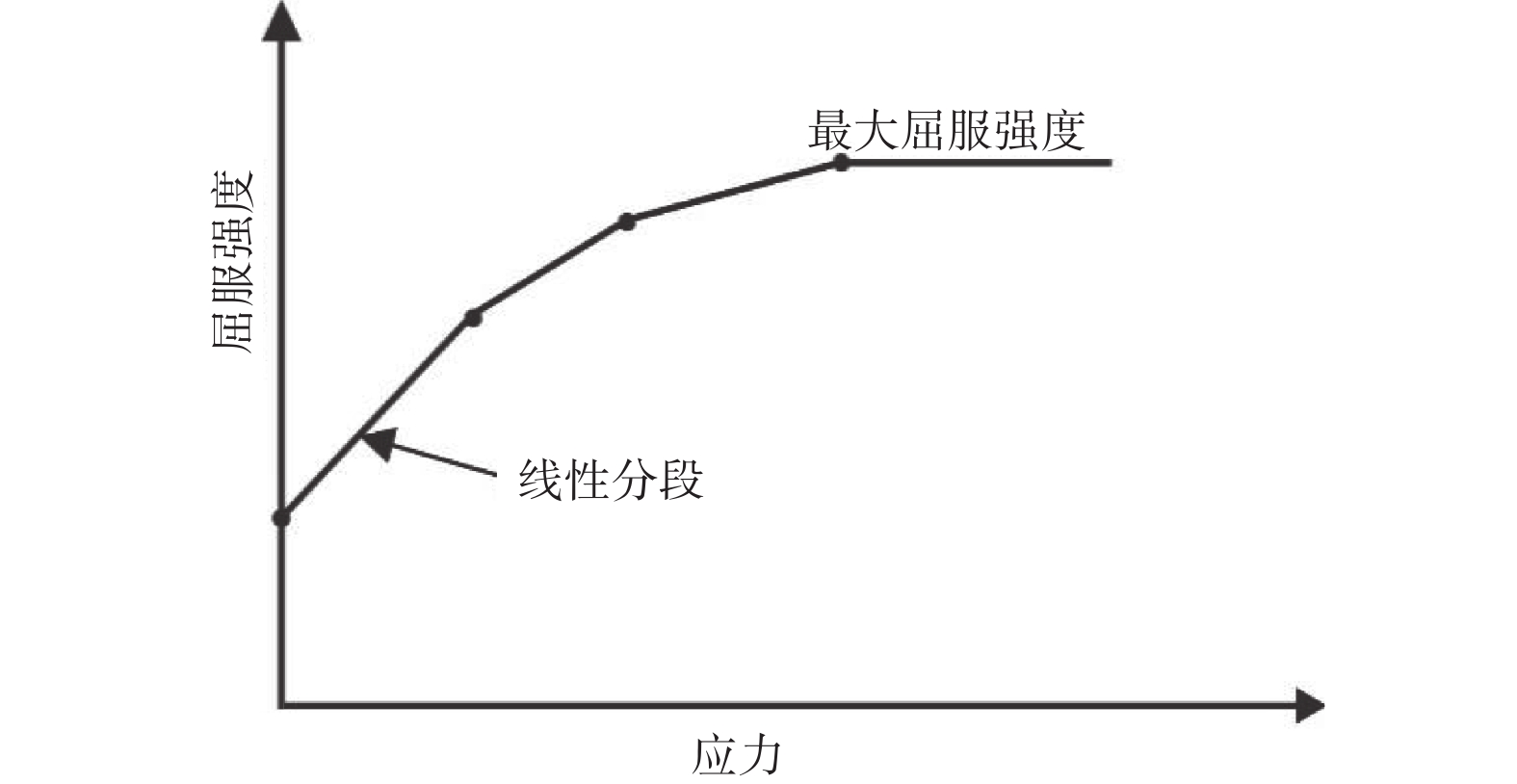

参数 取值 剪切模量G / kPa 7.70 002 × 107 Hugoniot弹性极限(HEL)/ kPa 6.570 000 × 105 初始屈服应力A / kPa 7.920 002 × 105 硬化常数B / kPa 5.100 001 × 105 应变速率常数C 0.014 000 热软化指数m 1.030 000 熔点$ {T}_{\mathrm{m}\mathrm{e}\mathrm{l}\mathrm{t}} $ / K 1 793.000 000 损伤常数D1 0.050 000 损伤常数D2 3.440 000 损伤常数D3 −2.120 000 损伤常数D4 0.002 000 损伤常数D5 0.610 000 表 2 混凝土分段D-P强度模型参数

Table 2. Concrete parameters of segmenting D-P strength model

参数 取值 剪切模量G /kPa 7.880 000 × 106 应力1 P1 / kPa 0.000 000 应力2 P2 / kPa 8.000 000 × 104 应力3 P3 / kPa 1.100 000 × 105 应力4 P4 / kPa 2.000 000 × 105 屈服强度1 σS1 / kPa 2.500 000 × 105 屈服强度2 σS2 / kPa 1.100 000 × 105 屈服强度3 σS3 / kPa 1.600 000 × 105 屈服强度4 σS4 / kPa 1.950 000 × 105 -

[1] 段隆臣, 谭松成. 金刚石工具在钢筋混凝土结构修复改造中的应用与研究现状 [J]. 探矿工程(岩土钻掘工程),2016,43(6):34-38. doi: 10.3969/j.issn.1672-7428.2016.06.008DUAN Longchen, TAN Songcheng. Application and research status of diamond tools on the repair and reconstruction of reinforced concrete structure [J]. Exploration Engineering (Rock & Soil Drilling and Tunneling),2016,43(6):34-38. doi: 10.3969/j.issn.1672-7428.2016.06.008 [2] SHALENNY V. Safe technologies for cutting reinforced concrete structures by means of diamond tools [C]. E3S Web of Conferences, 2019, 97: 03009. [3] 丁星妤, 吴晶晶. 薄壁钻头中金刚石定位排布参数设计 [J]. 湖南城市学院学报(自然科学版),2021,30(4):6-9. doi: 10.3969/j.issn.1672-7304.2021.04.0002DING Xingyu, WU Jingjing. Parameter design of diamond positioning arrangement in thin-wall bit [J]. Journal of Hunan City University (Natural Science),2021,30(4):6-9. doi: 10.3969/j.issn.1672-7304.2021.04.0002 [4] 吴勇, 傅帝尹, 罗怀明, 等. 深基坑内支撑无损拆除施工方法的应用 [J]. 施工技术,2020,40(S1):65-68.WU Yong, FU Diyin, LUO Huaiming, et al. Application of nondestructive demolition construction method of deep foundation excavation inner support [J]. Construction Technology,2020,40(S1):65-68. [5] 羊自力, 胡珊珊, 王艳, 等. 基于小波分析的金刚石锯片锯切混凝土加工状态及表面质量分析 [J]. 工具技术,2018,52(4):45-51. doi: 10.3969/j.issn.1000-7008.2018.04.009YANG Zili, HU Shanshan, WANG Yan, et al. Machining state and surface quality analysis of diamond saw blade sawing concrete based on wavelet analysis [J]. Tool Engineering,2018,52(4):45-51. doi: 10.3969/j.issn.1000-7008.2018.04.009 [6] HU H X, CHEN W, DENG C, et al. Effect of matrix composition on the performance of Fe-based diamond bits for reinforced concrete structure drilling [J]. International Journal of Refractory Metals and Hard Materials,2021,95:105419. doi: 10.1016/j.ijrmhm.2020.105419 [7] CHEN B, CHEN P, HUANG Y, et al. Blade segment with a 3D lattice of diamond grits fabricated via an additive manufacturing process [J]. Chinese Journal of Mechanical Engineering,2020,33(5):195-206. doi: 10.1186/s10033-020-00496-6 [8] 孙志超, 刘新琛, 张宝鹏. 金刚石锯片切割混凝土的切削力影响因素分析 [J]. 中国民航大学学报,2018,36(3):58-61. doi: 10.3969/j.issn.1674-5590.2018.03.012SUN Zhichao, LIU Xinchen, ZHANG Baopeng. Influencing factors analyses of concrete cutting force of diamond saw blade [J]. Journal of Civil Aviation University of China,2018,36(3):58-61. doi: 10.3969/j.issn.1674-5590.2018.03.012 [9] FANG Z, HARRISON J P. Development of a local degradation approach to the modelling of brittle fracture in heterogeneous rocks [J]. International Journal of Rock Mechanics and Mining Sciences,2002,39:443-457. doi: 10.1016/S1365-1609(02)00035-7 [10] PRADEEP L. Studies on the formation of discontinuous chips during rock cutting using an explicit finite element model [J]. International Journal of Advanced Manufacturing Technology,2014,70:635-648. doi: 10.1007/s00170-013-5309-y [11] HUANG H, DETOURNAY E. Intrinsic length scales in tool-rock interaction [J]. International Journal of Geomechanics,2008,8(1):39-44. doi: 10.1061/(ASCE)1532-3641(2008)8:1(39) [12] CHEN C S, PAN E, AMADEI B. Fracture mechanics analysis of cracked discs of anisotropic rock using the boundary element method [J]. International Journal of Rock Mechanics and Mining Sciences and Geomechanics Abstracts,1998,35(2):195-218. doi: 10.1016/S0148-9062(97)00330-6 [13] 陈昌雄. 特殊结构金刚石圆锯片性能研究 [D]. 南宁: 广西大学, 2006.CHEN Changxiong. Study on the performance of special structure diamond saw blade [D]. Nanning: Guangxi University, 2006. [14] 刘会宁. 特殊结构金刚石圆锯片干切混凝土的动力特性及实验研究 [D]. 南宁: 广西大学, 2007.LIU Huining. Dynamical and experimental study on special structure diamond saw blade dry-cutting concrete [D]. Nanning: Guangxi University, 2007. [15] 鞠军伟. 开圆形降噪孔金刚石圆锯片振动噪声研究 [D]. 济南: 山东大学, 2015.JU Junwei. Vibration noise study on diamond circular saw blades with round noise reduction holes [D]. Jinan: Shandong University, 2015. [16] 叶鲁浩. 耳型消音缝金刚石圆锯片振动与声辐射特性研究 [D]. 济南: 山东大学, 2016.YE Luhao. Study on vibration and sound radiation characteristics of diamond saw blades with ear-shape silencing seams [D]. Jinan: Shandong University, 2015. [17] 张林中. 金刚石切削岩石的模拟 [D]. 北京: 中国地质大学(北京), 2008.ZHANG Linzhong. The simulation of cutting rocks by diamond [D]. Beijing: China University of Geosciences (Beijing), 2008. [18] 肖月. 废弃核设施拆除金刚石绳锯机的切削热与磨损特性研究 [D]. 哈尔滨: 哈尔滨工程大学, 2019.XIAO Yue. Research on wear performance and cutting heat of diamond wire sawing machine in abandoned nuclear facility [D]. Harbin: Harbin Engineering University, 2019. [19] 茹聪. 金刚石串珠绳解体退役核设施的切削特性及切屑回收技术研究 [D]. 哈尔滨: 哈尔滨工程大学, 2020.RU Cong. Research on the cutting characteristics and chip recovery technology of the decommissioning nuclear facility of diamond string [D]. Harbin: Harbin Engineering University, 2020. [20] 孙永泉. 核设施解体绳锯机设计及切削机理的分子动力学仿真研究 [D]. 哈尔滨工程大学, 2021.SUN Yongquan. Design of diamond wire saw for nuclear facility demolition and MD simulation for cutting mechanism [D]. Harbin: Harbin Engineering University, 2021. [21] GINGOLD R A, MONAGHAN J J. Binary fission in damped rotating polytropes [J]. Monthly Notices of the Royal Astronomical Society,1978,184:481-499. doi: 10.1093/mnras/184.3.481 [22] GRAY J A, MONAGHAN J J. Numerical modelling of stress fields and fracture around magma chambers [J]. Journal of Volcanology and Geothermal Research,2004,135:259-283. doi: 10.1016/j.jvolgeores.2004.03.005 [23] LIU M B, LIU G R. Smoothed particle hydrodynamics (SPH): An overview and recent developments [J]. Archives of Computational Methods in Engineering,2010,17:25-76. doi: 10.1007/s11831-010-9040-7 [24] JOHNSON R, COOK W K. A constitutive model and data for metals subjected to large strains high strain rates and high temperatures [C]. The 7th International Symposium on Ballistics: Hague, 1983, 541-547. [25] DRUCKER D C, PRAGER W. Soil mechanics and plastic analysis or limit design [J]. Quarterly of Applied Mathematics,1952,10:157-165. doi: 10.1090/qam/48291 -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS