Experiment and simulation of single diamond abrasive particle scratching RB-SiC composite material

-

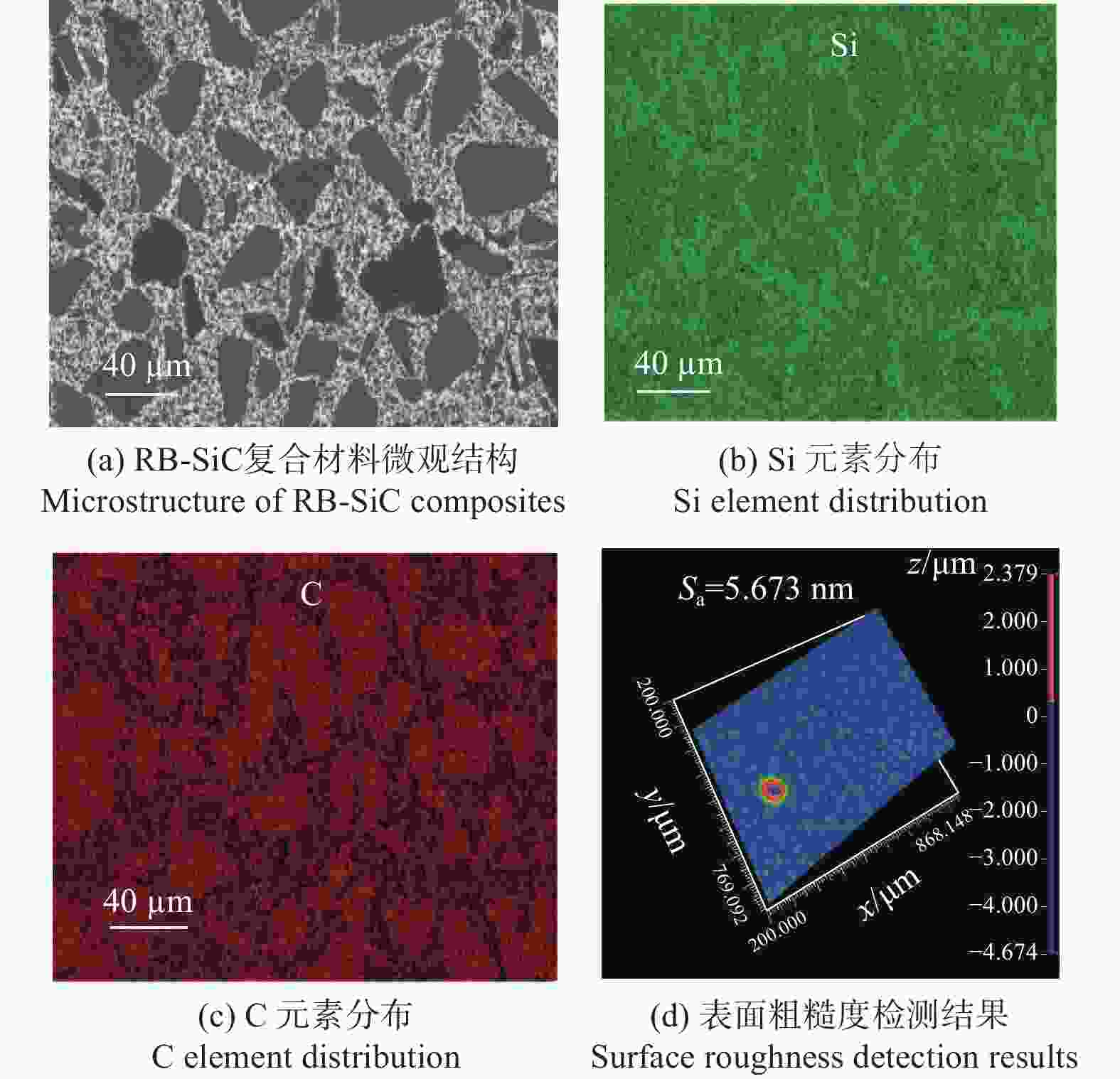

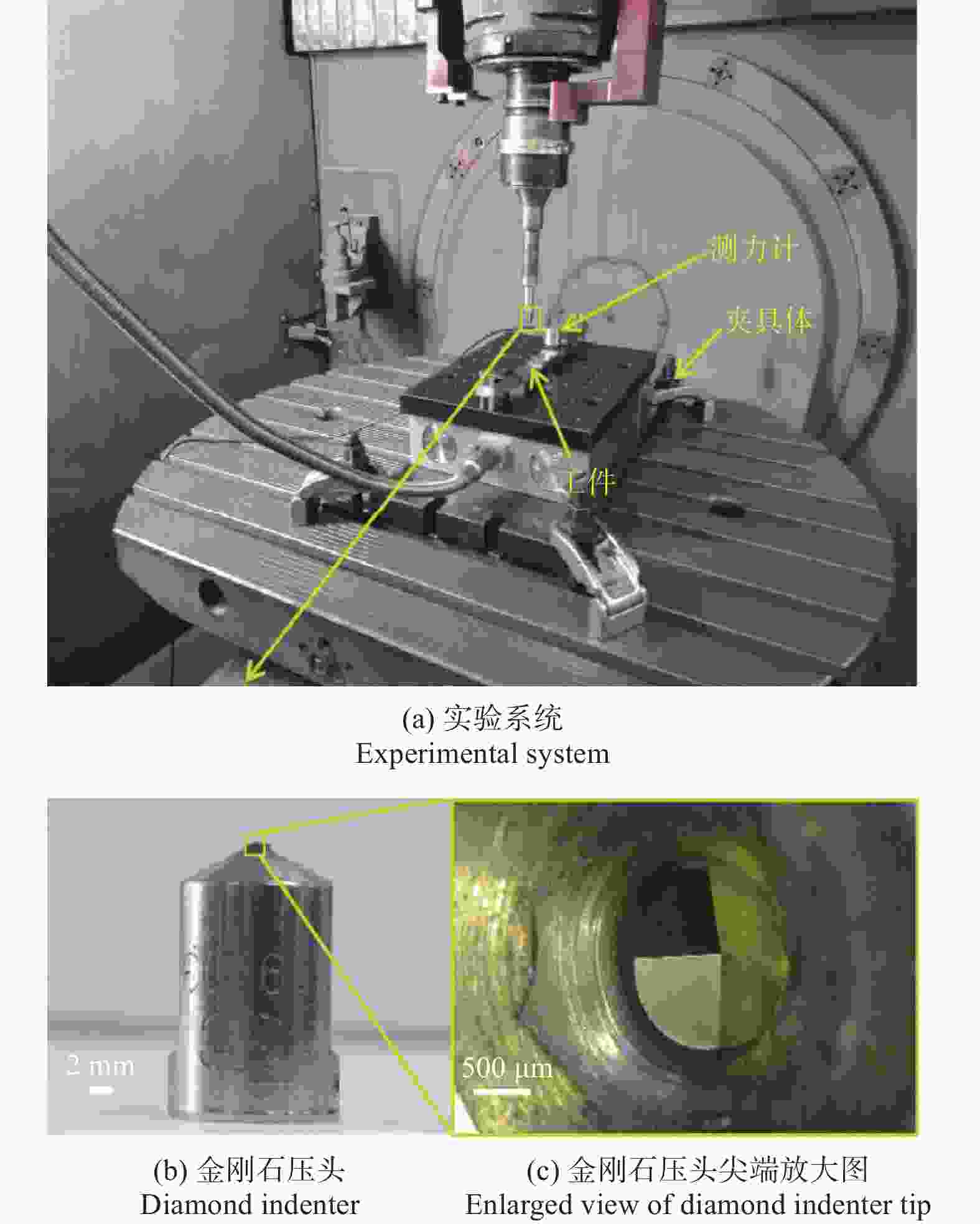

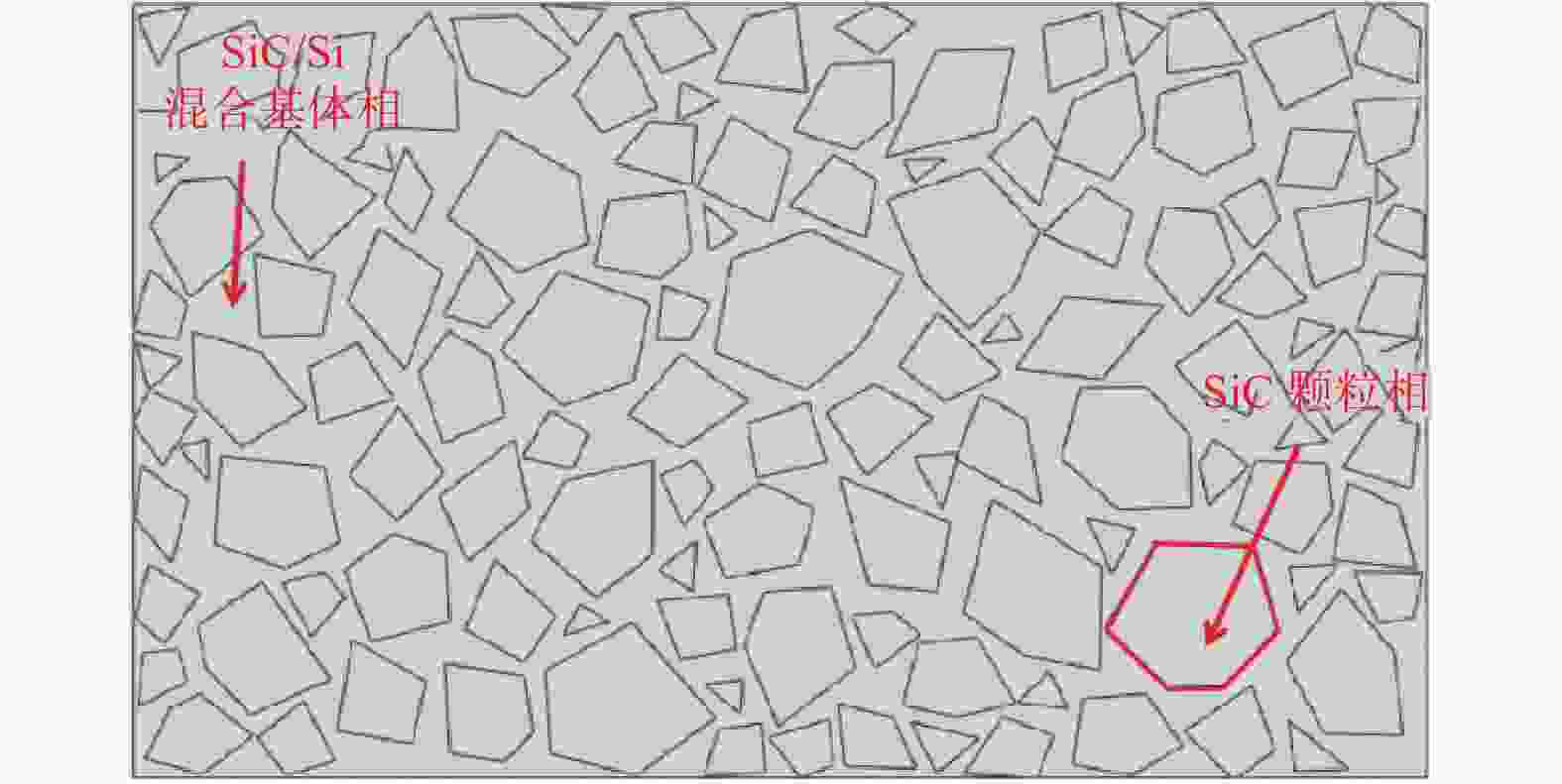

摘要: 反应烧结碳化硅(RB-SiC)复合材料具有比刚度高、硬度高、耐腐蚀和耐磨损等优异性能,被广泛用于航空航天等领域,然而其较高的硬度和脆性等导致使用传统加工方式时易出现较多缺陷。为探究RB-SiC复合材料磨削加工时的材料去除机理及表面损伤成因,开展单颗金刚石磨粒压头划擦实验,同时以连续分布的Si为基体,以呈颗粒或粉末状分布的SiC相为增强相,构建新的RB-SiC复合材料有限元仿真模型,并利用ABAQUS有限元仿真软件进行划擦仿真,研究复合材料表面的裂纹形成及材料去除机理,掌握划擦过程中压头−颗粒相互作用导致的切削力变化规律。结果表明,划擦实验与模型仿真结果吻合情况较好。随着切削深度增加,切削力逐渐增大,划痕路径上的破碎范围变大,材料表面形貌变差;当切削深度大于塑脆转变深度时,材料以脆性去除为主,划擦产生的应力向前传递,产生沿晶和穿晶裂纹;且划擦产生的应力大于SiC颗粒断裂应力,使SiC颗粒破碎去除,而基体则塑性去除;SiC颗粒与金刚石磨粒尖端的轨迹相对位置及SiC颗粒间距会导致划擦力变化,位于金刚石磨粒尖端移动轨迹上的SiC颗粒会导致划擦力上升,SiC颗粒间距过近时则划擦力会突升并在后方SiC颗粒破碎后骤降。

-

关键词:

- RB-SiC复合材料 /

- 单颗金刚石划擦 /

- 有限元仿真 /

- 划擦力

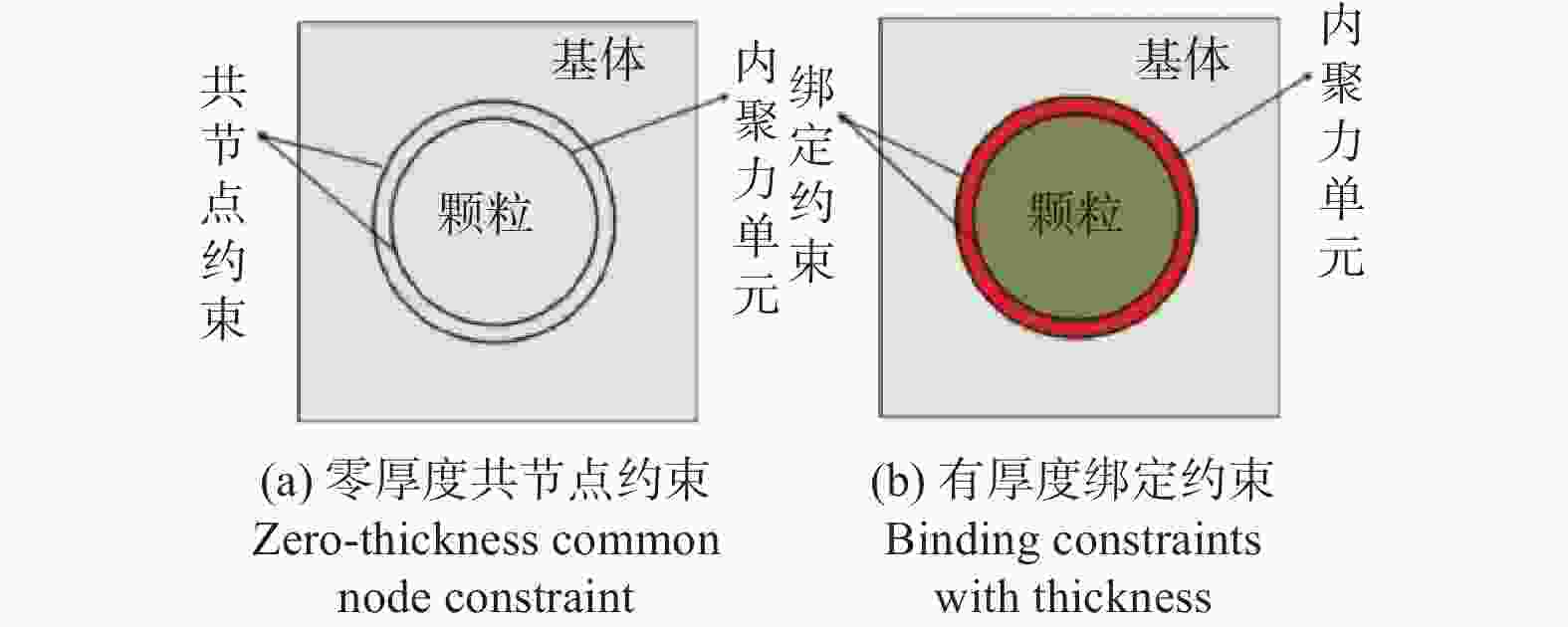

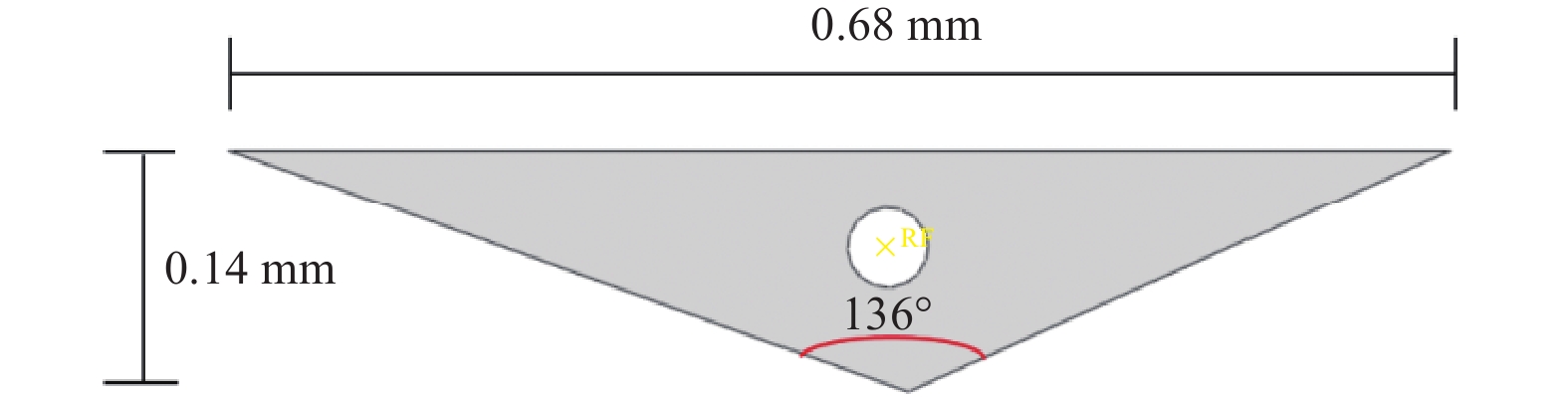

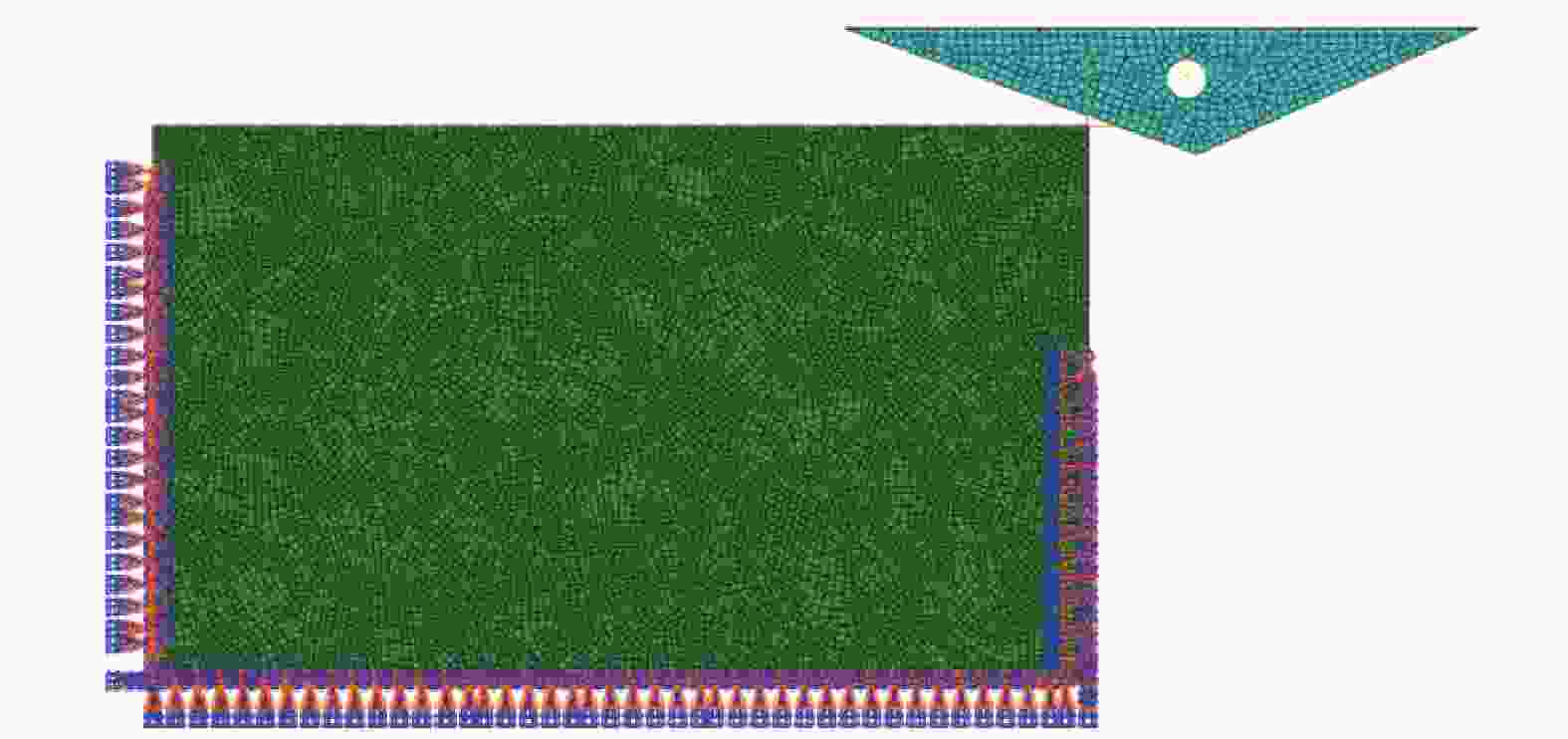

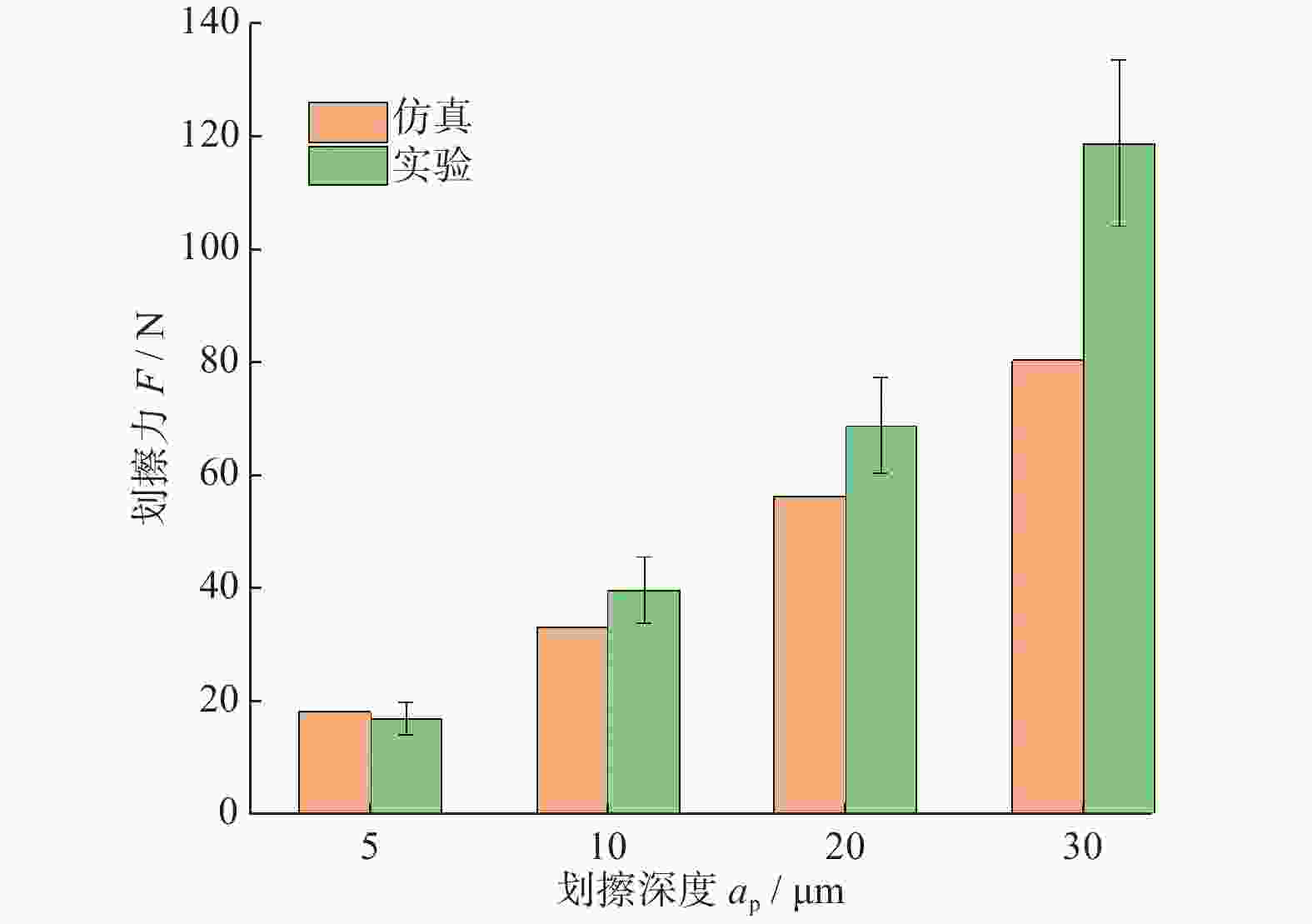

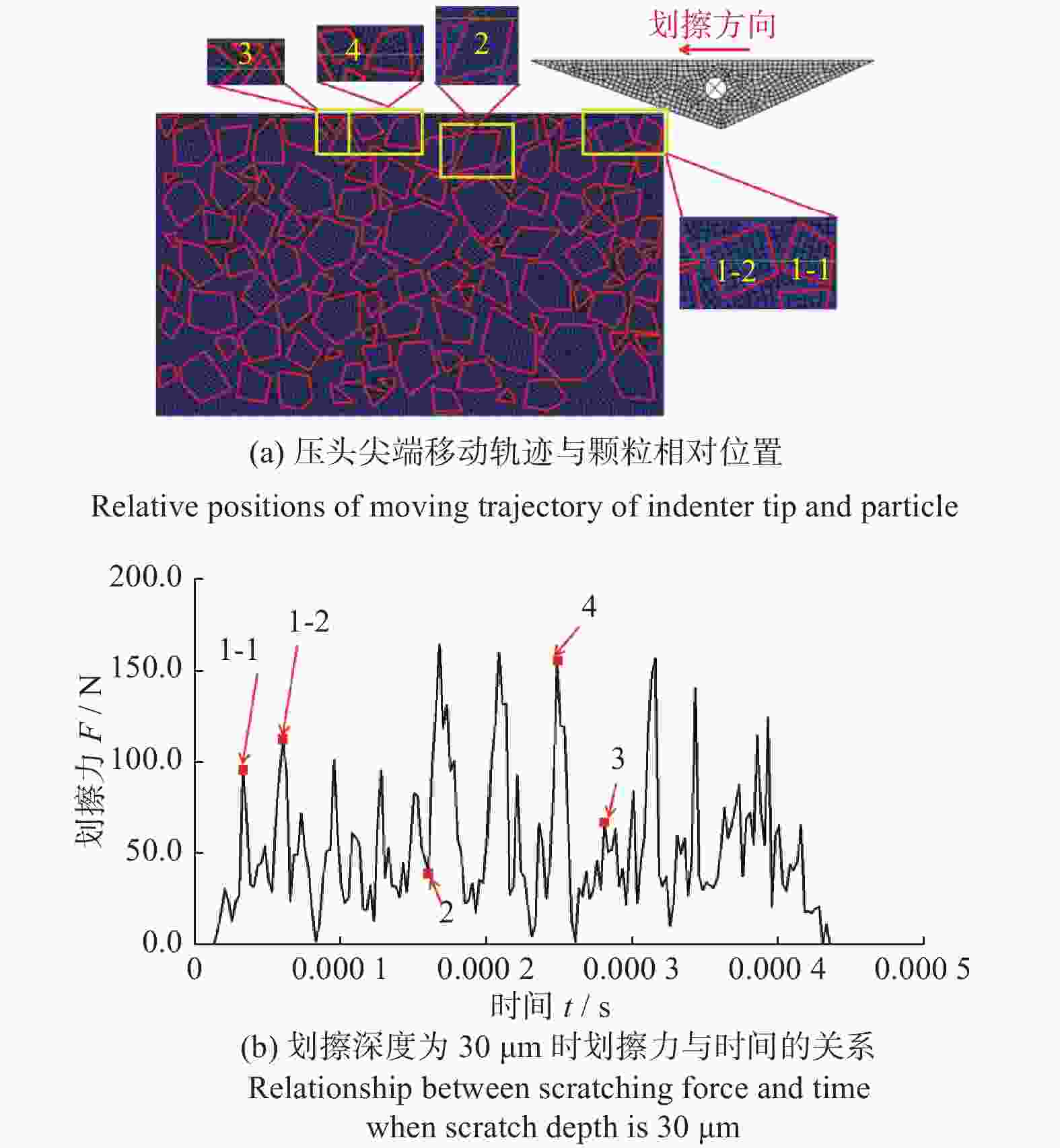

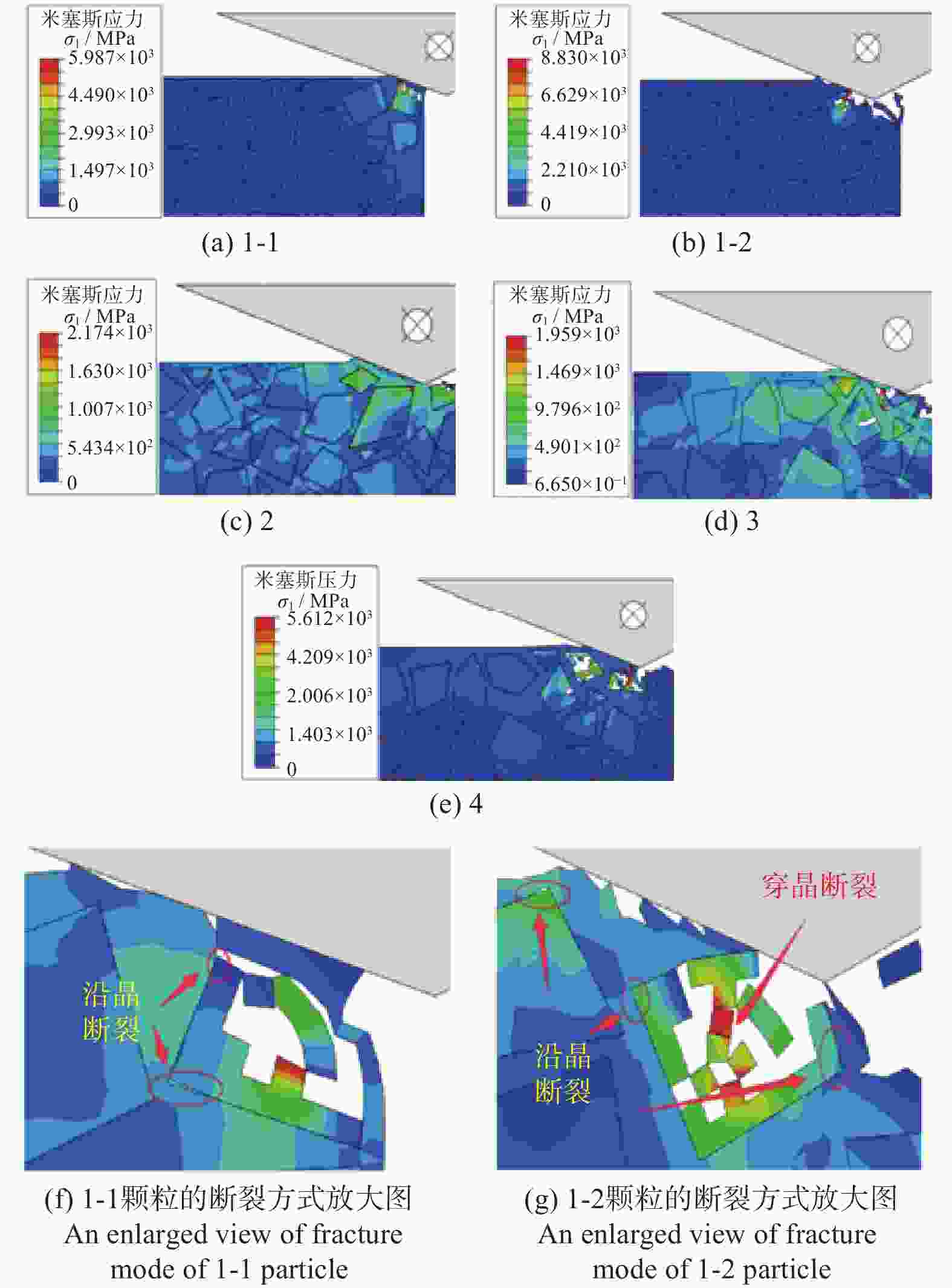

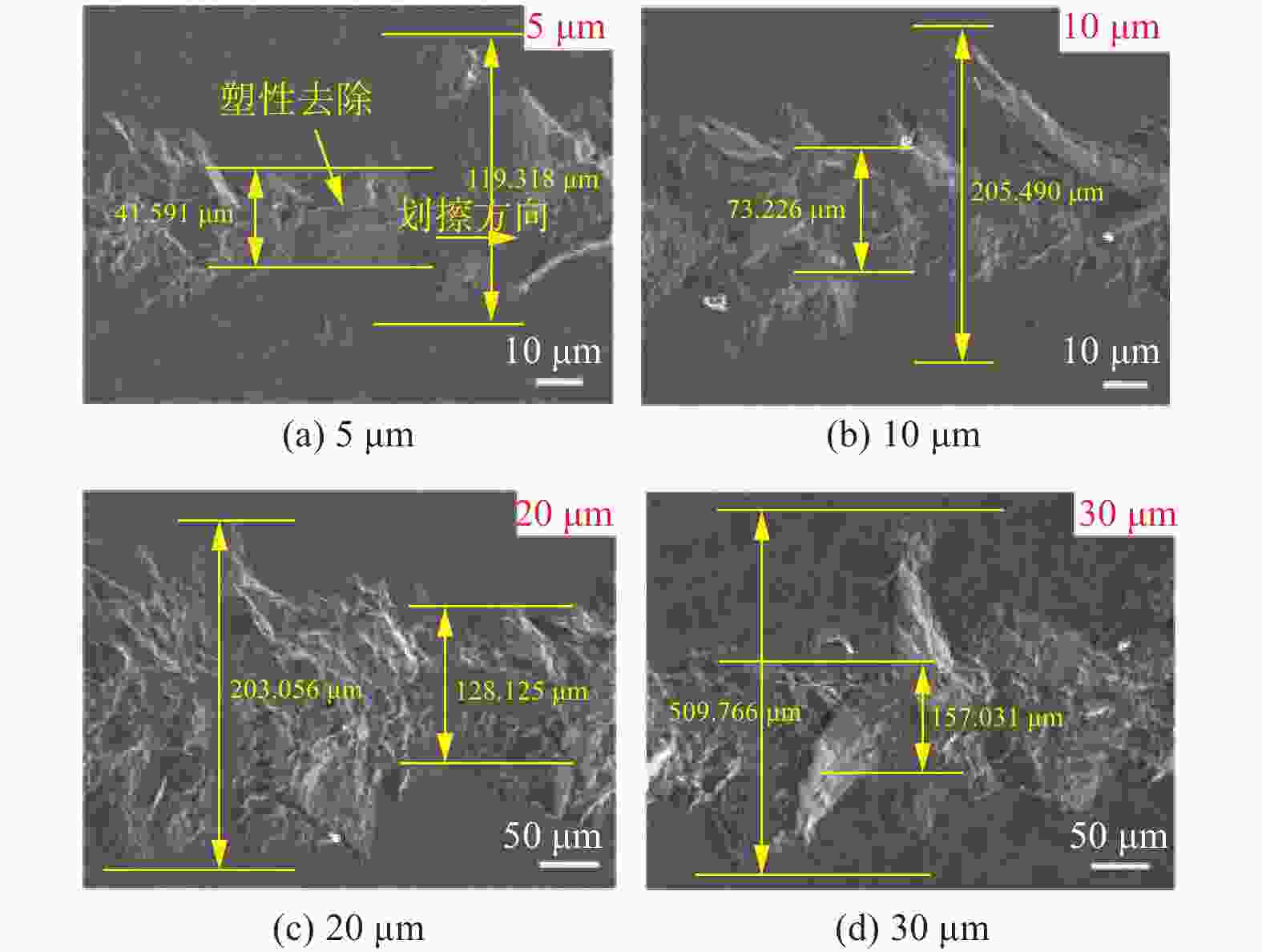

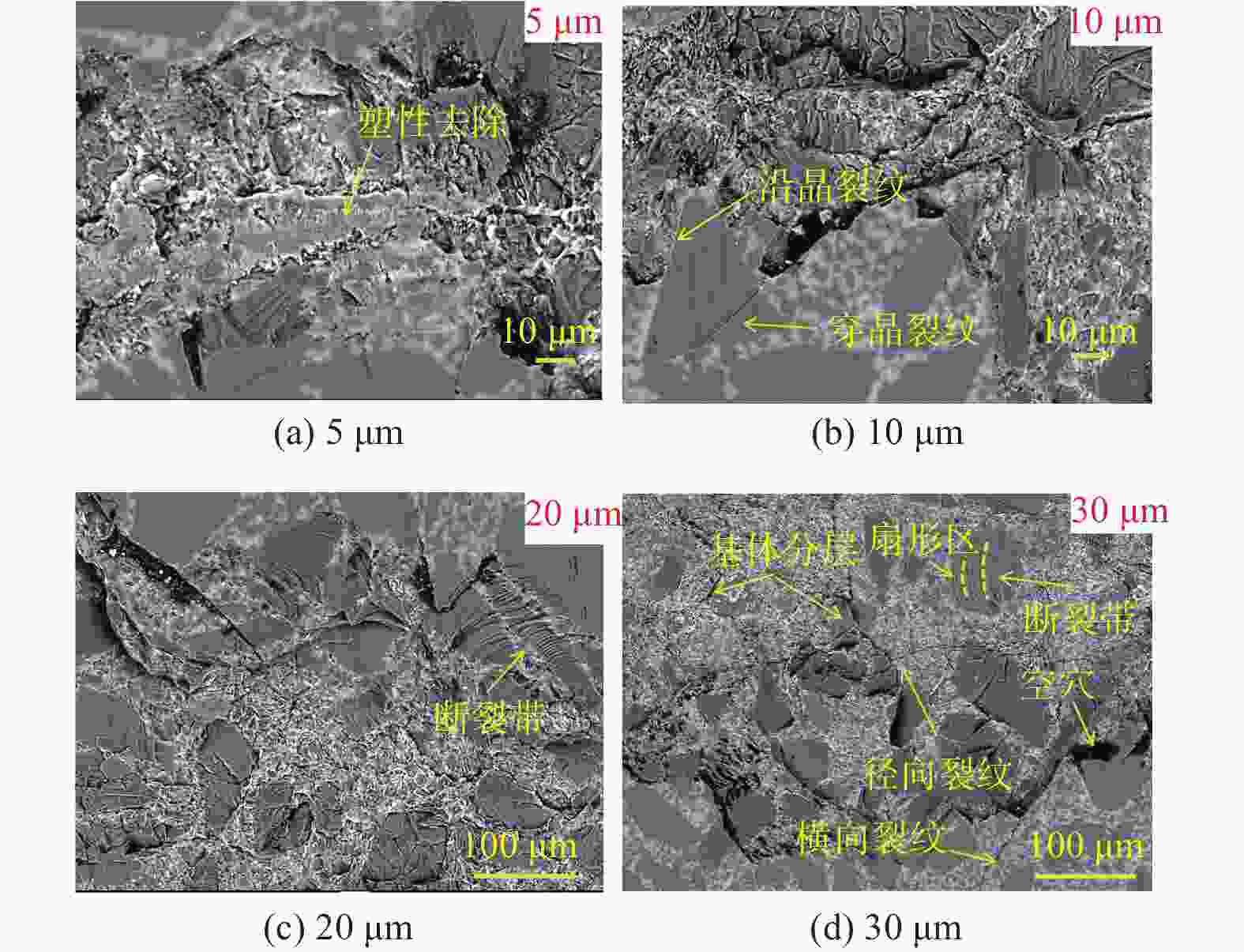

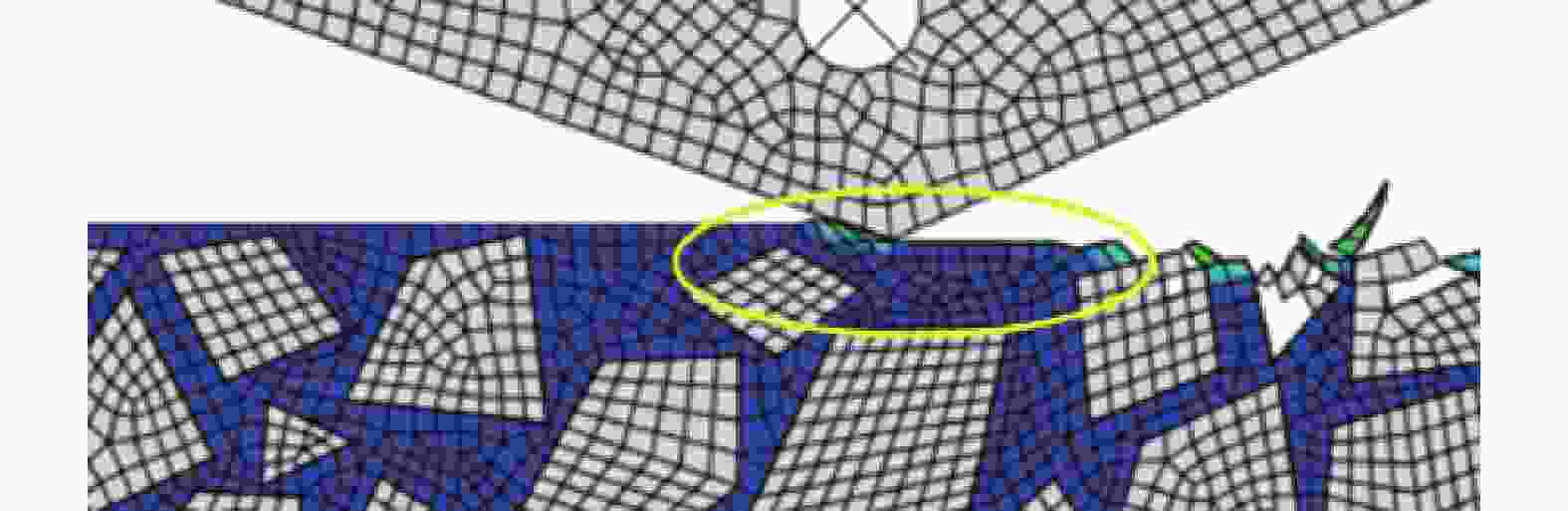

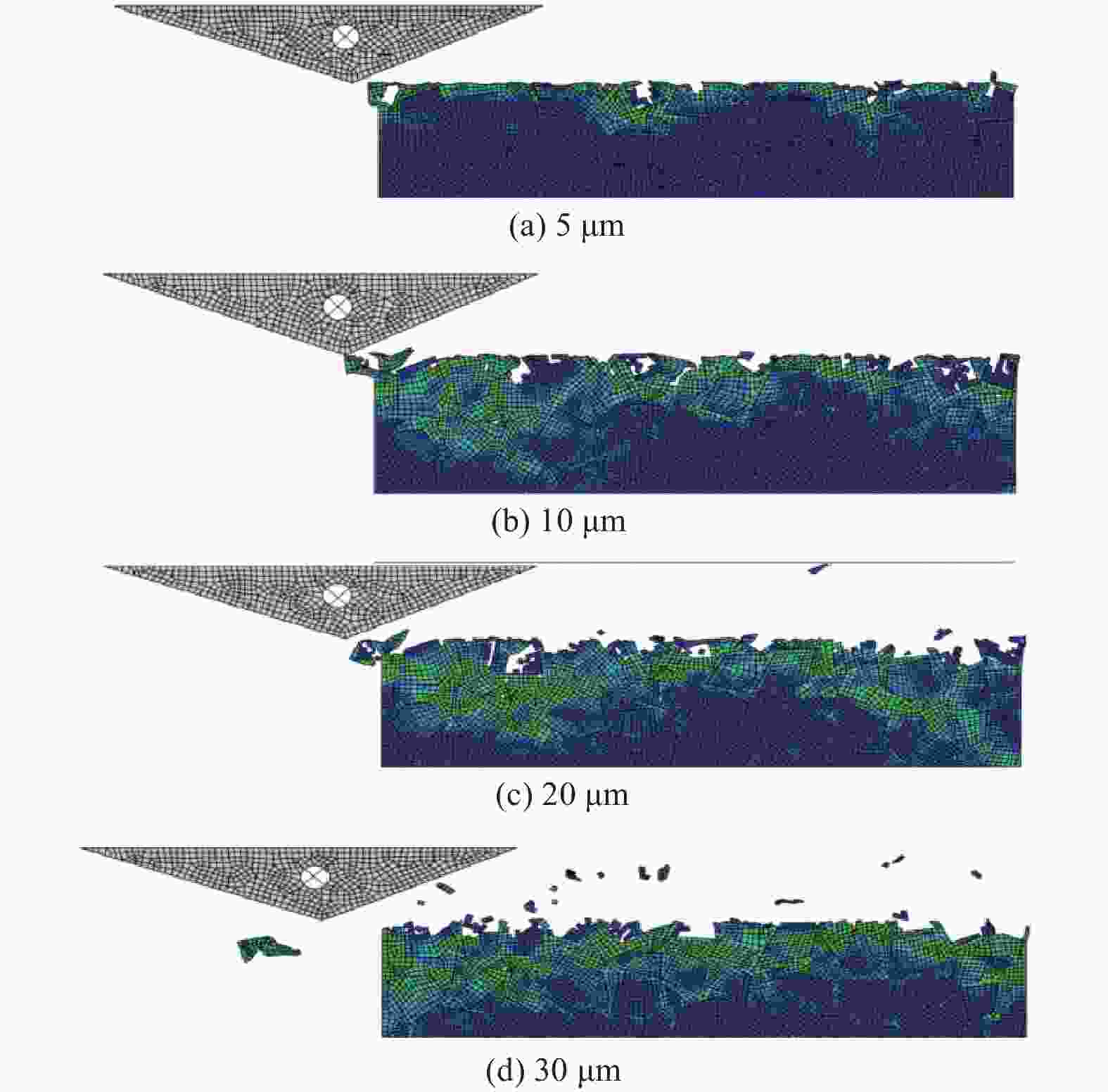

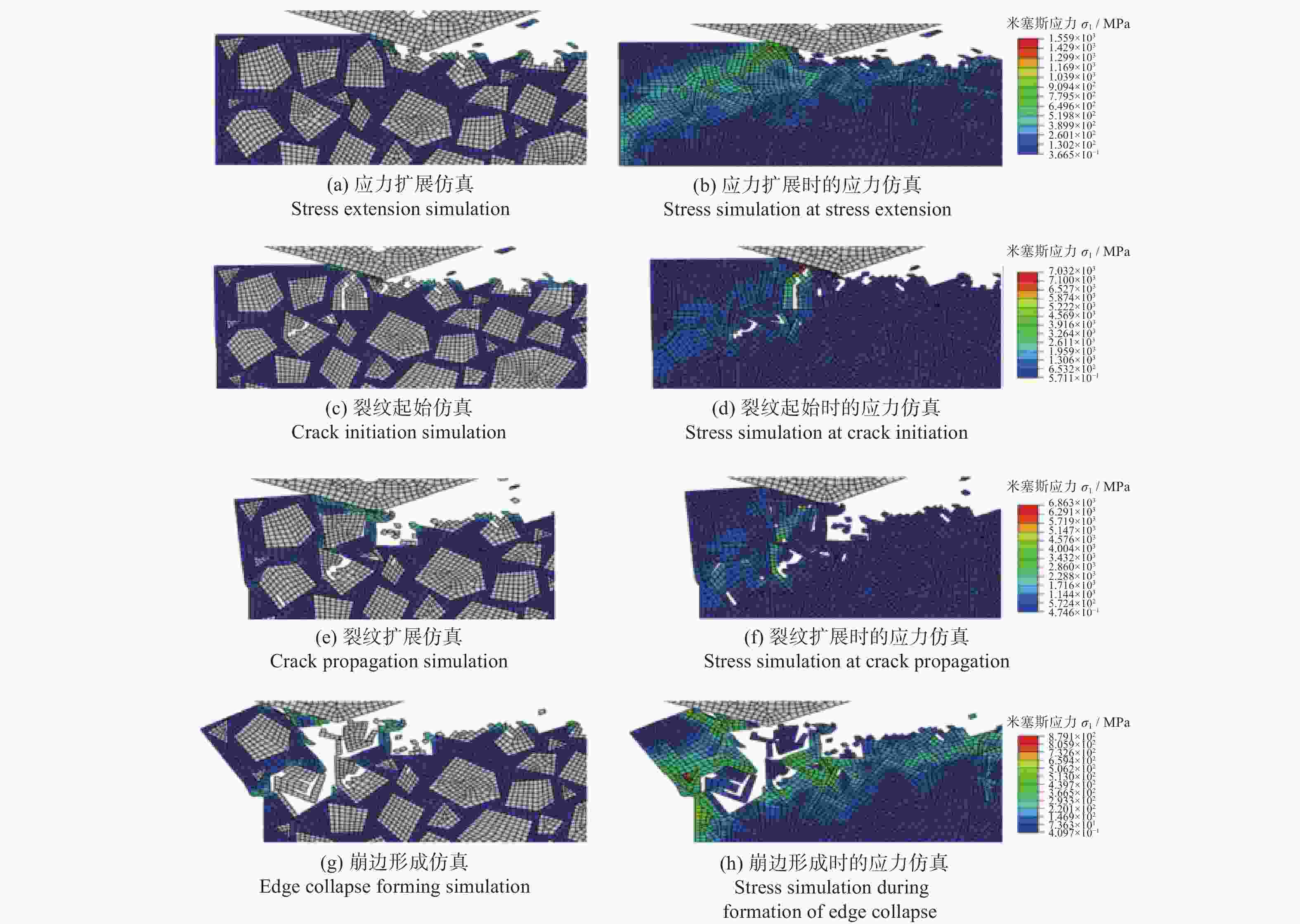

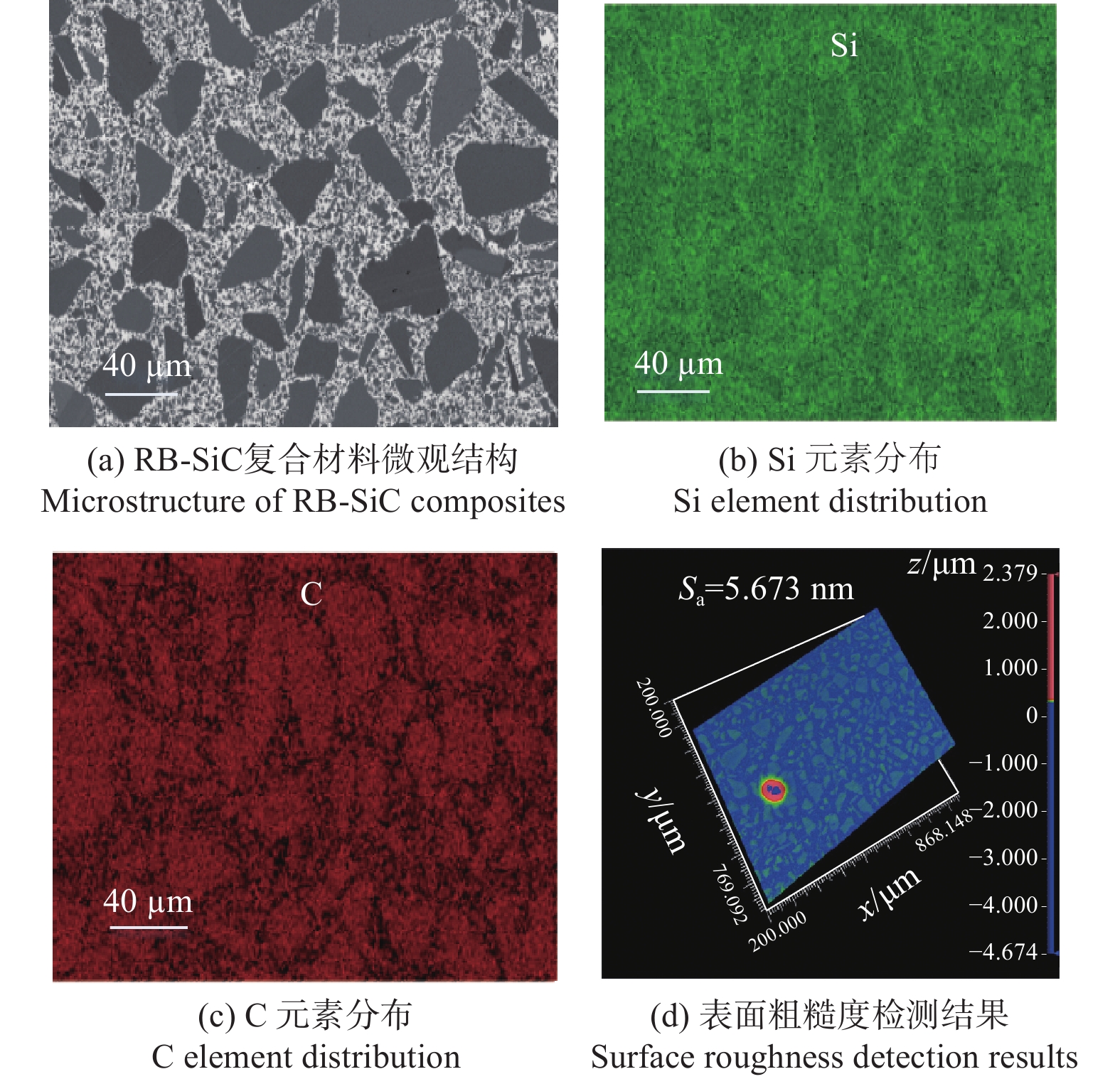

Abstract:Objectives Reaction-sintered silicon carbide (RB-SiC) composite materials have excellent properties such as high specific stiffness, high hardness, and corrosion resistance, and are widely used in important equipment such as space telescopes and aerospace combustion chambers. However, the high hardness and brittleness lead to many defects when processed using traditional methods. To investigate the material removal mechanism and the surface damage causes during the grinding process of RB-SiC composite materials, the ABAQUS finite element software is used for scratch simulation and the scratching experiment of a single diamond abrasive indenter is used for verification. Methods Based on ABAQUS finite element simulation software, a scratch simulation model of RB-SiC composite material with a multiphase structure is constructed. The model uses a continuously distributed Si and β - SiC mixture as the matrix, characterized using the Drucker Prager elastoplastic constitutive model. The SiC reinforcement phase distributed in particle or powder form is characterized using brittle fracture as the failure criterion, and a zero-thickness cohesive unit interface layer is established between the two phases. The relationship between the scratch force and the scratch depth is investigated by a single abrasive particle scratch experiment, and compared with the simulation model. The material removal mechanism and the causes of surface damage are then obtained. Results In the simulation, it is found that the variation of scratching force is closely related to the relative position between the particles and the pressure head. The scratching forces of particles in the middle of the trajectory suddenly increase, while particles above the trajectory have a smaller impact on scratching force. The particles below the trajectory have a slightly smaller impact on scratching force than those above. When the pressure head penetrates the middle of the particle, its stress is greater than the particle fracture strength, causing transgranular fracture of the particle. At the same time, the crack continues to propagate to the boundary between the two phases and deflects along the boundary. The particles above the trajectory will be removed as a whole with the removal of the matrix material. When multiple particles are in close proximity and sequentially in contact with the indenter, the stress concentration during the fragmentation of the front particles and the plastic deformation of the matrix is greater than the fracture stress of the rear particles, resulting in the collapse of the rear particles before they come into direct contact with the indenter. The deformed matrix that has lost particle support and has not been completely removed will be pushed to the next particle by the indenter, causing a sudden drop in scratching force. The scratch experiment shows that the crushing width of the scratch path increases with the increase of scratch depth. When the scratch depth is 5 μm, the material surface is relatively flat, and the material is mainly removed by plastic deformation of the matrix. When the scratch depth increases to 30 μm, the brittle peeling phenomenon of the material becomes more and more obvious, and the surface morphology of the material also deteriorates. It can be observed that the cleavage and fragmentation of particles, the voids formed by particle extraction, the transverse cracks, and the matrix delamination and fan-shaped fracture zone are caused by the diagonal downward propagation of the medium diameter crack. This is because the scratch depth is much greater than the plastic brittle transition depth of the material, and the material is mainly removed by brittleness. Conclusions By establishing a two-phase finite element simulation two-dimensional model for single abrasive particle scratching simulation and conducting experimental verification, it is found that the surface morphology of scratches deteriorates with increasing scratching depth, and the scratching force gradually decreases with decreasing scratching depth. Moreover, the simulation and the experimental scratching force values for small scratching depths are in good agreement. The relative position between the SiC particles and the diamond indenter tip trajectory, as well as the spacing between the SiC particles, leads to changes in scratching force. The SiC particles located above the trajectory will cause the scratching force to increase significantly. When the scratch depth is shallow and there are no original SiC particles near the surface, plastic removal will still occur. The subsurface cracks start at the particle-matrix interface and spread along the particle phase boundary to form micro-cracks. When the outlet support of the material is insufficient, the micro-cracks of different depths will expand and converge, eventually producing the phenomenon of material edge collapse. This study provides a theoretical basis and simulation verification for the removal mechanism and damage formation causes of RB-SiC materials. -

表 1 RB-SiC复合材料的基本力学性能参数[9]

Table 1. Basic mechanical property parameters of RB-SiC composite materials[9]

参数 取值 密度 ρ1 / (g·cm−3) 3.16 弹性模量 E1 / GPa 420 泊松比 ε1 0.17 断裂韧性 KIC / (MPa·m1/2) 3.04 维氏硬度 HV / MPa 2 002 表 2 实验条件

Table 2. Testing condition

实验编号 划擦深度 ap / μm 划擦速度 v / (m·s−1) 1 5 2.4 2 10 2.4 3 20 2.4 4 30 2.4 表 3 基体材料的本构模型参数

Table 3. Constitutive model parameters of matrix material

参数 取值 密度 ρ2 / (g·cm−3) 2975 弹性模量 E2 / MPa 385 870 泊松比 ε2 0.24 初始屈服强度 σ / MPa 800 摩擦角 β / (°) 15 膨胀角 Ψ / (°) −1 流应力比 R 0.9 -

[1] ZOU Y, LI C H, TANG Y H, et al. Preform impregnation to optimize the properties and microstructure of RB-SiC prepared with laser sintering and reactive melt infiltration [J]. Journal of the European Ceramic Society,2020,40(15):5186-5195. doi: 10.1016/j.jeurceramsoc.2020.07.023 [2] ZHANG Z Z, YAO P, WANG J, et al. Nanomechanical characterization of RB-SiC ceramics based on nanoindentation and modelling of the ground surface roughness [J]. Ceramics International,2020,46(5):6243-6253. doi: 10.1016/j.ceramint.2019.11.094 [3] DONG Z C, CHENG H B. Ductile mode grinding of reaction-bonded silicon carbide mirrors [J]. Applied Optics,2017,56(26):7404-7412. doi: 10.1364/AO.56.007404 [4] LI Q S, ZHANG Y J, SUN H B, et al. Effect of carbon black content and molding pressure on the thermal conductivity of SiC/Si ceramic composites [J]. Key Engineering Materials,2015,655:58-61. doi: 10.4028/www.scientific.net/KEM.655.58 [5] 李志鹏. RB-SiC陶瓷磨削损伤形成机制及抑制技术研究 [D]. 哈尔滨: 哈尔滨工业大学, 2019.LI Zhipeng. Research on grinding damage formation mechanism and suppression technology of RB-SiC ceramics [D]. Harbin: Harbin Institute of Technology, 2019. [6] 王亚茹, 李英杰, 邹莱, 等. RB-SiC金刚石磨粒柔性刻划材料去除及表面损伤行为 [J]. 光学精密工程,2022,30(14):1704-1715. doi: 10.37188/OPE.20223014.1704WANG Yaru, LI Yingjie, ZOU Lai, et al. Material removal and surface damage behavior of diamond grain for flexible scribing RB-SiC [J]. Optics and Precision Engineering,2022,30(14):1704-1715. doi: 10.37188/OPE.20223014.1704 [7] RAO X S, ZHANG F H, LUO X C, et al. Material removal mode and friction behaviour of RB-SiC ceramics during scratching at elevated temperatures [J]. Journal of the European Ceramic Society,2019,39(13):3534-3545. doi: 10.1016/j.jeurceramsoc.2019.05.015 [8] 韩腊. 反应烧结碳化硅振动辅助切削加工工艺研究 [D]. 哈尔滨: 哈尔滨工业大学, 2019.HAN La. Research on vibration-assisted cutting process of reaction-bonded silicon carbide [D]. Harbin: Harbin Institute of Technology, 2019 [9] 高峰. RB-SiC超声辅助磨削及剩余强度研究 [D]. 大连: 大连理工大学, 2016.GAO Feng. Study on ultrasonic assisted grinding of RB-SiC and residual strength abstract [D]. Dalian: Dalian University of Technology, 2016. [10] DRUCKER D C, PRAGER W. Soil mechanics and plastic analysis or limit design [J]. Quarterly of Applied Mathematics,1952,10(2):157-165. doi: 10.1090/qam/48291 [11] 胡传奇, 刘海林, 黄小婷, 等. 反应烧结碳化硅的显微结构和力学性能分析 [J]. 中国陶瓷工业,2020,27(5):7-11. doi: 10.13958/j.cnki.ztcg.2020.05.002HU Chuanqi, LIU Hailin, HUANG Xiaoting, et al. Microstructure and mechanical properties of reaction sintered silicon carbide [J]. China Ceramic Industry,2020,27(5):7-11. doi: 10.13958/j.cnki.ztcg.2020.05.002 [12] TURSUN G, WEBER U, SOPPA E, et al. The influence of transition phases on the damage behaviour of an Al/10vol.%SiC composite [J]. Computational Materials Science,2006,37(1/2):119-133. doi: 10.1016/j.commatsci.2005.12.018 [13] LIU J W, CHENG K, DING H, et al. Simulation study of the influence of cutting speed and tool-particle interaction location on surface formation mechanism in micromachining SiCp/Al composites [J]. Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science,2018,232(11):2044-2056. doi: 10.1177/0954406217713521 [14] 武永祥. SiCp/Al复合材料切削仿真研究与实验验证 [D]. 哈尔滨: 哈尔滨工业大学, 2017.WU Yongxiang. Research on the cutting simulation of SiCp/Al composite and experimental verification [D]. Harbin: Harbin Institute of Technology, 2017 [15] 王涛. 高体积分数SiCp/Al复合材料高速铣削基础研究 [D]. 北京: 北京理工大学, 2015.WANG Tao. Fundamental study on high speed milling of high volume fraction SiCp/Al composite [D]. Beijing: Beijing Institute of Technology, 2015. [16] 徐春光. SiCp/Al材料振动切削界面层损伤机理仿真与实验研究 [D]. 大连: 大连交通大学, 2020.XU Chunguang. Simulation and experimental research on the damage machanism of interface layer in SiCp/Al materials during vibration cutting [D]. Dalian: Dalian Jiaotong University, 2020. [17] DANDEKAR C R, SHIN Y C. Multi-step 3-D finite element modeling of subsurface damage in machining particulate reinforced metal matrix composites [J]. Composites Part A: Applied Science and Manufacturing,2009,40(8):1231-1239. doi: 10.1016/j.compositesa.2009.05.017 [18] WILLIAMS J J, SEGURADO J, LLORCA J, et al. Three dimensional (3D) microstructure-based modeling of interfacial decohesion in particle reinforced metal matrix composites [J]. Materials Science & Engineering A,2012,557:113-118. doi: 10.1016/j.msea.2012.05.108 [19] UMER U, ASHFAQ M, QUDEIRI J A, et al. Modeling machining of particle-reinforced aluminum-based metal matrix composites using cohesive zone elements [J]. The International Journal of Advanced Manufacturing Technology,2015,78(5):1171-1179. doi: 10.1007/s00170-014-6715-5 [20] LI Z P, ZHANG F H, LUO X C, et al. Fundamental understanding of the deformation mechanism and corresponding behavior of RB-SiC ceramics subjected to nano-scratch in ambient temperature [J]. Applied Surface Science,2019,469:674-683. doi: 10.1016/j.apsusc.2018.11.090 [21] SONG S G, VAIDYA R U, ZUREK A K, et al. Stacking faults in sic particles and their effect on the fracture behavior of a 15 Vol Pct SiC/6061-AI matrix composite [J]. Metallurgical and Materials Transactions A,1996,27(2):459-465. doi: 10.1007/BF02648423 [22] MENG B B, ZHANG Y, ZHANG F H. Material removal mechanism of 6H-SiC studied by nano-scratching with Berkovich indenter [J]. Applied Physics A: Materials Science & Processing,2016,122(3):247. doi: 10.1007/s00339-016-9802-7 [23] 肖亚航, 傅敏士. SiC颗粒中的堆垛层错及其对SiC/6061-Al基复合材料断裂性能的影响 [J]. 国外金属热处理,2001(2):27-30. doi: 10.3969/j.issn.1673-4971.2001.02.009XIAO Yahang, FU Minshi. Stacking fault in SiC particles and its effect on fracture properties of SiC/6061-Al matrix composites [J]. Heat Treatment of Metals Abroad,2001(2):27-30. doi: 10.3969/j.issn.1673-4971.2001.02.009 -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS