| [1] |

王亮亮, 赵波, 殷森. 金属表面疏水性研究进展 [J]. 表面技术,2017,46(12):153-161. doi: 10.16490/j.cnki.issn.1001-3660.2017.12.025WANG Liangliang, ZHAO Bo, YIN Sen. Hydrophobicity of metal surface [J]. Surface Technology,2017,46(12):153-161. doi: 10.16490/j.cnki.issn.1001-3660.2017.12.025

|

| [2] |

SANTOS L M, LANG A, WAHIDI R, et al. Passive separation control of shortfin mako shark skin in a turbulent boundary layer [J]. Experimental Thermal and Fluid Science,2021,128:110433. doi: 10.1016/j.expthermflusci.2021.110433

|

| [3] |

CHEN H W, ZHANG P F, ZHANG L W, et al. Continuous directional water transport on the peristome surface of nepenthes alata [J]. Nature,2016,532(7579):85-89. doi: 10.1038/nature17189

|

| [4] |

张德远, 陈华伟, 张鑫, 等. 军用仿生技术发展趋势 [J]. 国防技术,2013,34(6):1-5, 10. doi: 10.3969/j.issn.1671-4547.2013.06.001ZHANG Deyuan, CHEN Huawei, ZHANG Xin, et al. The development and future of bionics in military application [J]. National Defense Science & Technology,2013,34(6):1-5, 10. doi: 10.3969/j.issn.1671-4547.2013.06.001

|

| [5] |

郑清春, 毛璐璐, 史于涛, 等. 仿生织构表面对人工髋关节副动压润滑性能及减摩性分析 [J]. 机械工程学报,2021,57(11):102-111. doi: 10.3901/JME.2021.11.102ZHENG Qingchun, MAO Lulu, SHI Yutao, et al. Analysis of biomimetic texture surface on dynamic compression lubrication and friction reduction of artificial hip pair [J]. Journal of Mechanical Engineering,2021,57(11):102-111. doi: 10.3901/JME.2021.11.102

|

| [6] |

TIAN Y L, HU B R, SONG J, et al. Bioinspired multiscale wrinkling patterns on curved substrates: An overview [J]. Nano-Micro Letter,2020,12(1):1-42. doi: 10.1007/s40820-020-00436-y

|

| [7] |

王东伟, 莫继良, 张琦, 等. 沟槽表面填充材料对界面摩擦振动噪声的影响 [J]. 摩擦学报,2017,37(5):647-655. doi: 10.16078/j.tribology.2017.05.012WANG Dongwei, MO Jiliang, ZHANG Qi, et al. Effect of filling material into grooves on the interfacial friction-induced vibration and noise [J]. Tribology,2017,37(5):647-655. doi: 10.16078/j.tribology.2017.05.012

|

| [8] |

LI X Y, LI Y P, MUZAMMIL I, et al. Antireflection and antiwetting functionalities of plasma-nanotextured polymer surfaces with biomimetic nanopillars [J]. Plasma Processes and Polymers,2020,17(11):e2000050. doi: 10.1002/ppap.202000050

|

| [9] |

FU X J, BA Y, SUN J J. Numerical study of thermocapillary migration behaviors of droplets on a grooved surface with a three-dimensional color-gradient lattice Boltzmann model [J]. Physics of Fluids,2021,33(6):062108. doi: 10.1063/5.0050081

|

| [10] |

王志远, 邢志国, 王海斗, 等. 液滴在固体织构化表面上的润湿行为研究现状 [J]. 机械工程学报,2022,58(1):124-144.WANG Zhiyuan, XING Zhiguo, WANG Haidou, et al. Research progress of droplet wetting behavior on solid textured surface [J]. Journal of Mechanical Engineering,2022,58(1):124-144.

|

| [11] |

PETE B, PETER L, EVA L U. Application of laser-ultrasonics to texture measurements in metal processing [J]. Acta Materialia,2017,123:329-336. doi: 10.1016/j.actamat.2016.10.043

|

| [12] |

WU Z, BAO H, XING Y Q, et al. Tribological characteristics and advanced processing methods of textured surfaces: a review [J]. The International Journal of Advanced Manufacturing Technology,2021,114:1241-1277. doi: 10.1007/s00170-021-06954-2

|

| [13] |

LAI L J, ZHOU H, ZHU L M. Fabrication of microlens array on silicon surface using electrochemical wet stamping technique [J]. Applied Surface Science,2016,364:442-445. doi: 10.1016/j.apsusc.2015.12.085

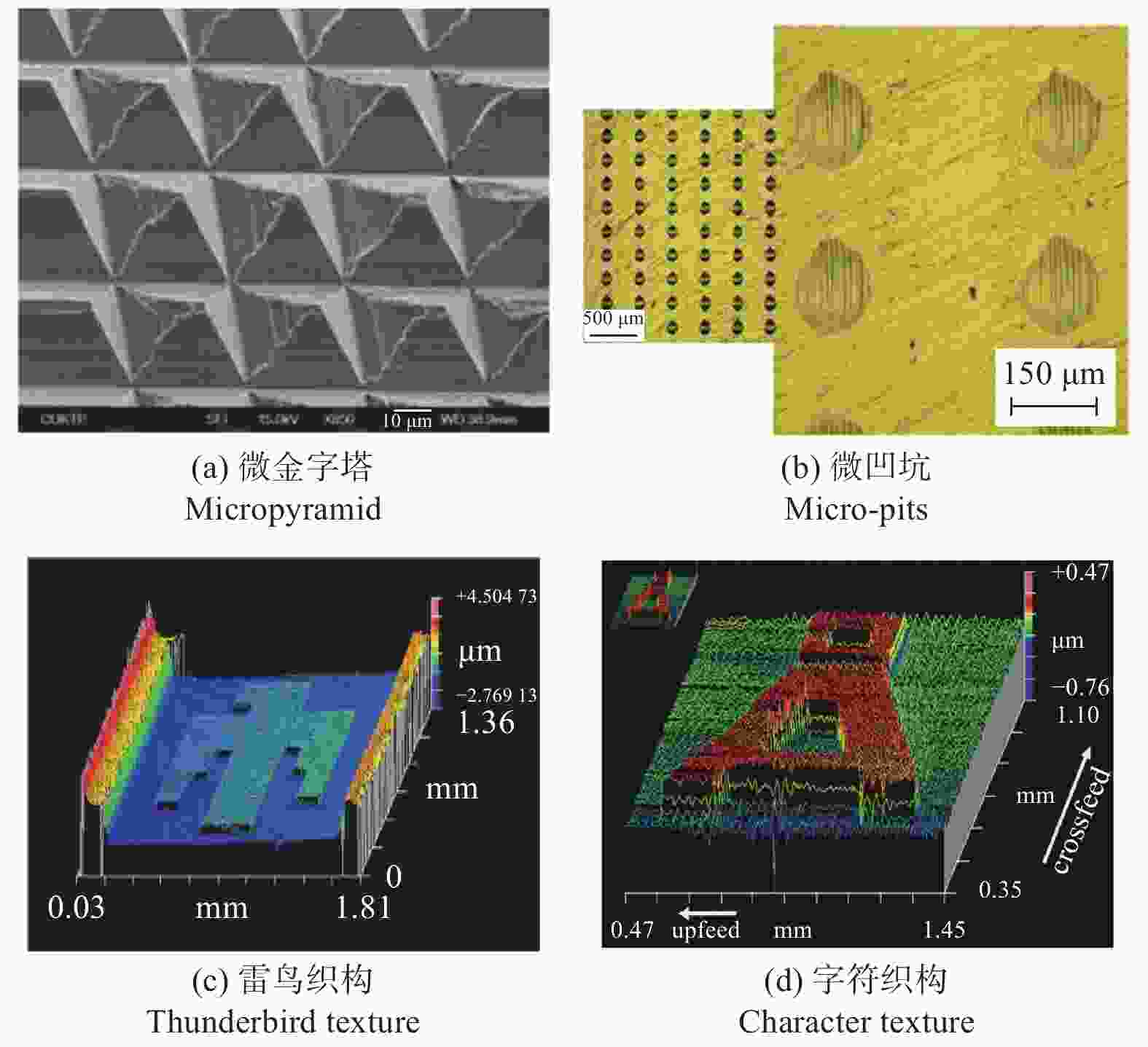

|

| [14] |

ZHANG H G, ZHANG Z, Gilchrist M. Advances in precision micro/nano-electroforming: A state-of-the-art review [J]. Journal of Micromechanics and Microengineering,2020,30(10):103002. doi: 10.1088/1361-6439/aba017

|

| [15] |

LIAO Z R, LA MONACA A, MURRY J, et al. Surface integrity in metal machining-part I: Fundamentals of surface characteristics and formation mechanisms [J]. International Journal of Machine Tools and Manufacture,2021,162:103687. doi: 10.1016/j.ijmachtools.2020.103687

|

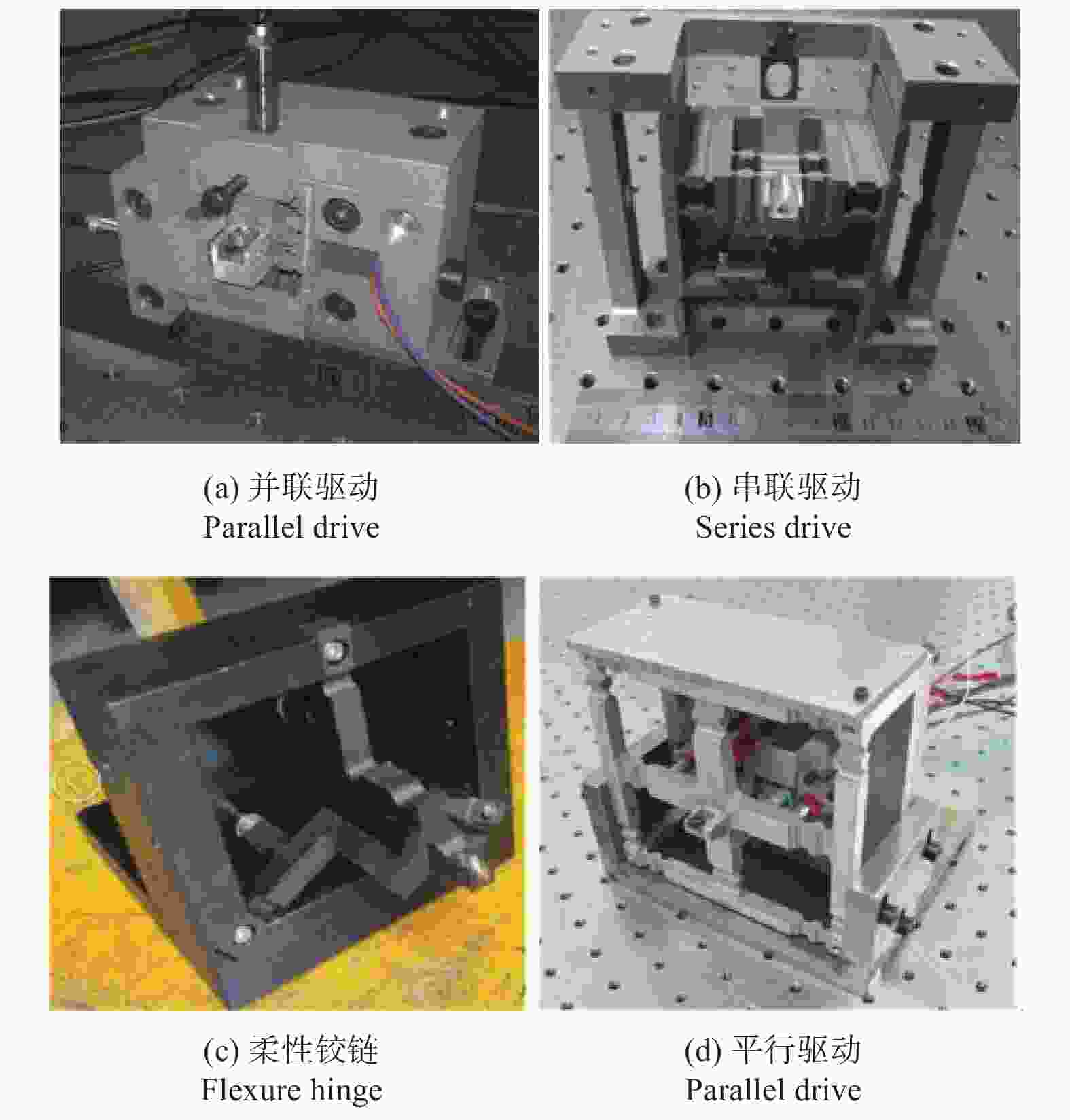

| [16] |

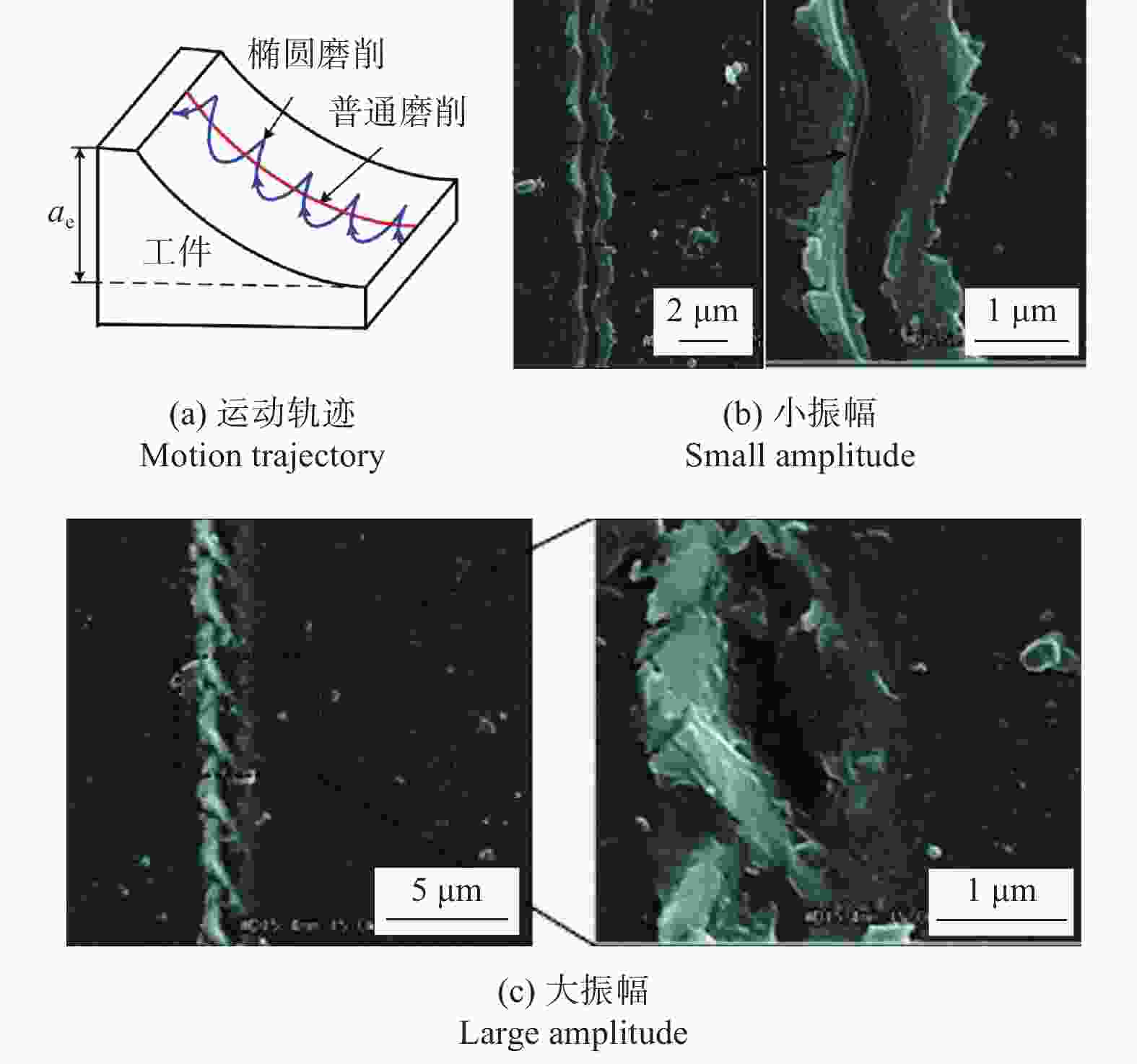

张存鹰, 赵波. 超声振动辅助加工表面微结构及其特性研究进展 [J]. 表面技术,2019,48(5):259-274. doi: 10.16490/j.cnki.issn.1001-3660.2019.05.038ZHANG Cunying, ZHAO Bo. Research progress of properties of surface micro-structure in ultrasonic vibration assisted machining [J]. Surface Technology,2019,48(5):259-274. doi: 10.16490/j.cnki.issn.1001-3660.2019.05.038

|

| [17] |

YANG Z C, ZHU L D, ZHANG G X, et al. Review of ultrasonic vibration-assisted machining in advanced materials [J]. International Journal of Machine Tools and Manufacture,2020,156:103594. doi: 10.1016/j.ijmachtools.2020.103594

|

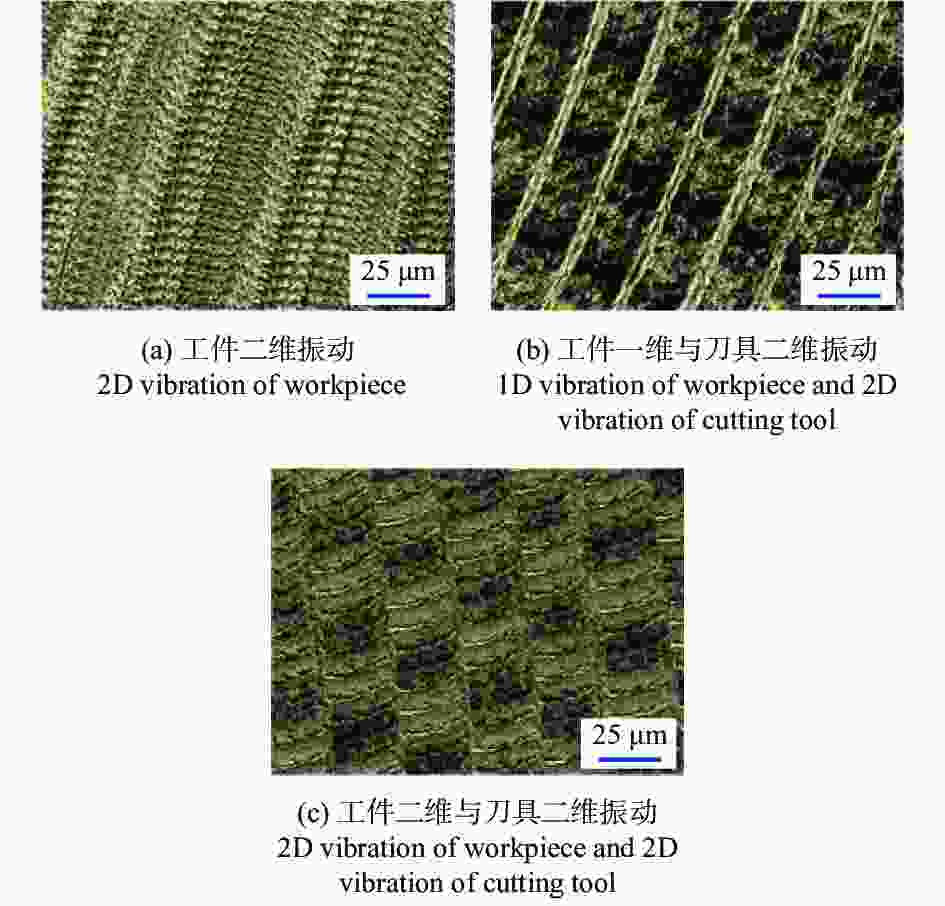

| [18] |

SONIA P, JAIN J K, SAXENA K K. Influence of ultrasonic vibration assistance in manufacturing processes: A Review [J]. Materials and Manufacturing Processes,2021,36(13):1451-1475. doi: 10.1080/10426914.2021.1914843

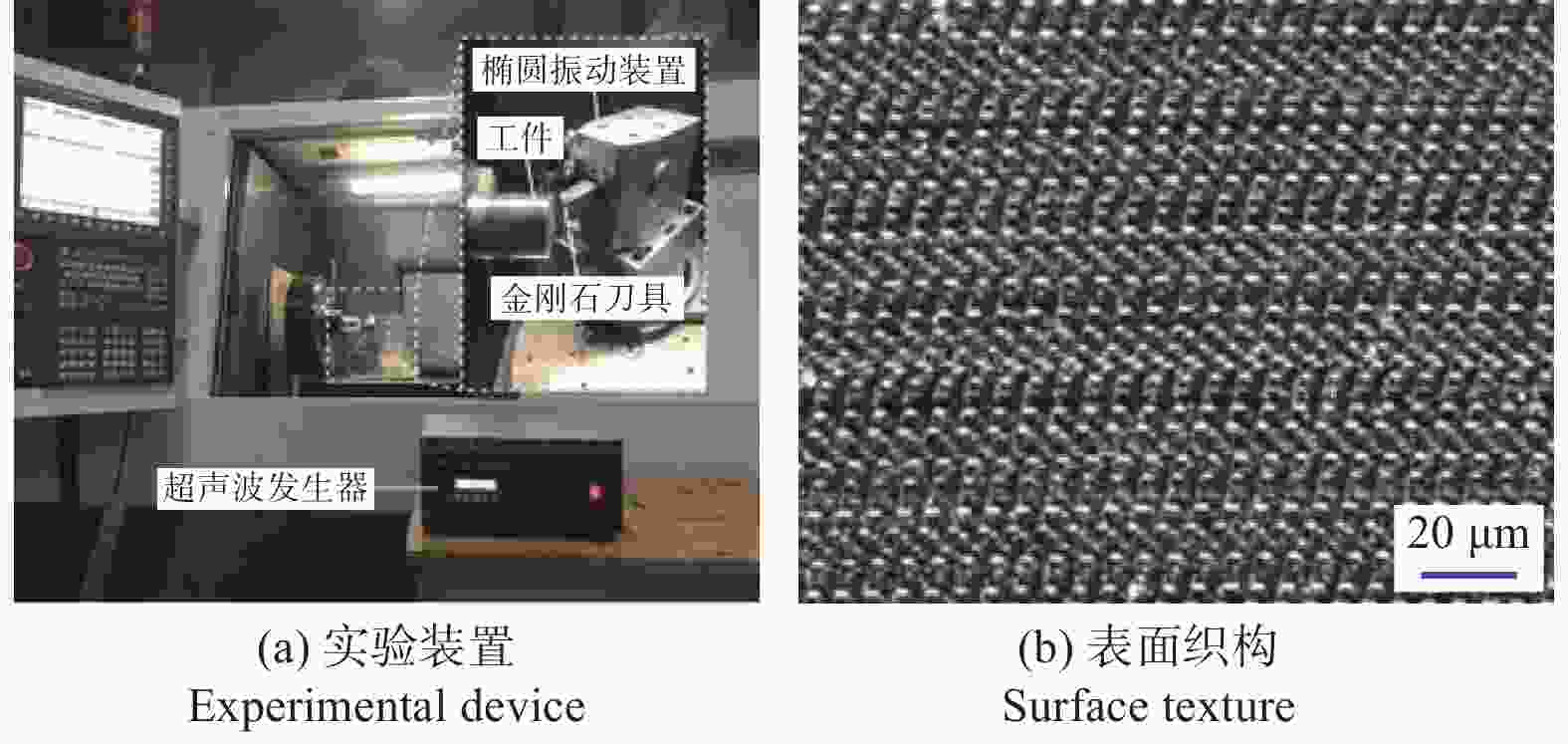

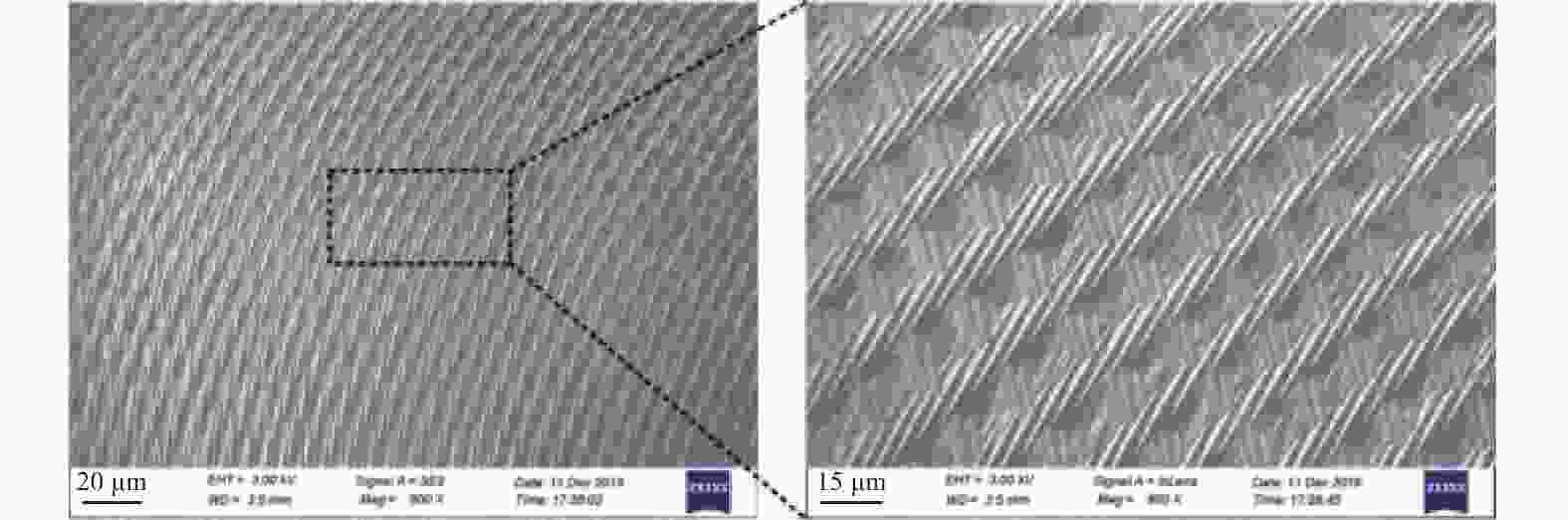

|

| [19] |

别文博, 赵波, 王晓博, 等. 超声加工在齿轮抗疲劳制造中的研究综述与展望 [J]. 表面技术,2018,47(7):35-51. doi: 10.16490/j.cnki.issn.1001-3660.2018.07.006BIE Wenbo, ZHAO Bo, WANG Xiaobo, et al. Overview and expectation on gear anti-fatigue manufacture by ultrasonic-assisted machining [J]. Surface Technology,2018,47(7):35-51. doi: 10.16490/j.cnki.issn.1001-3660.2018.07.006

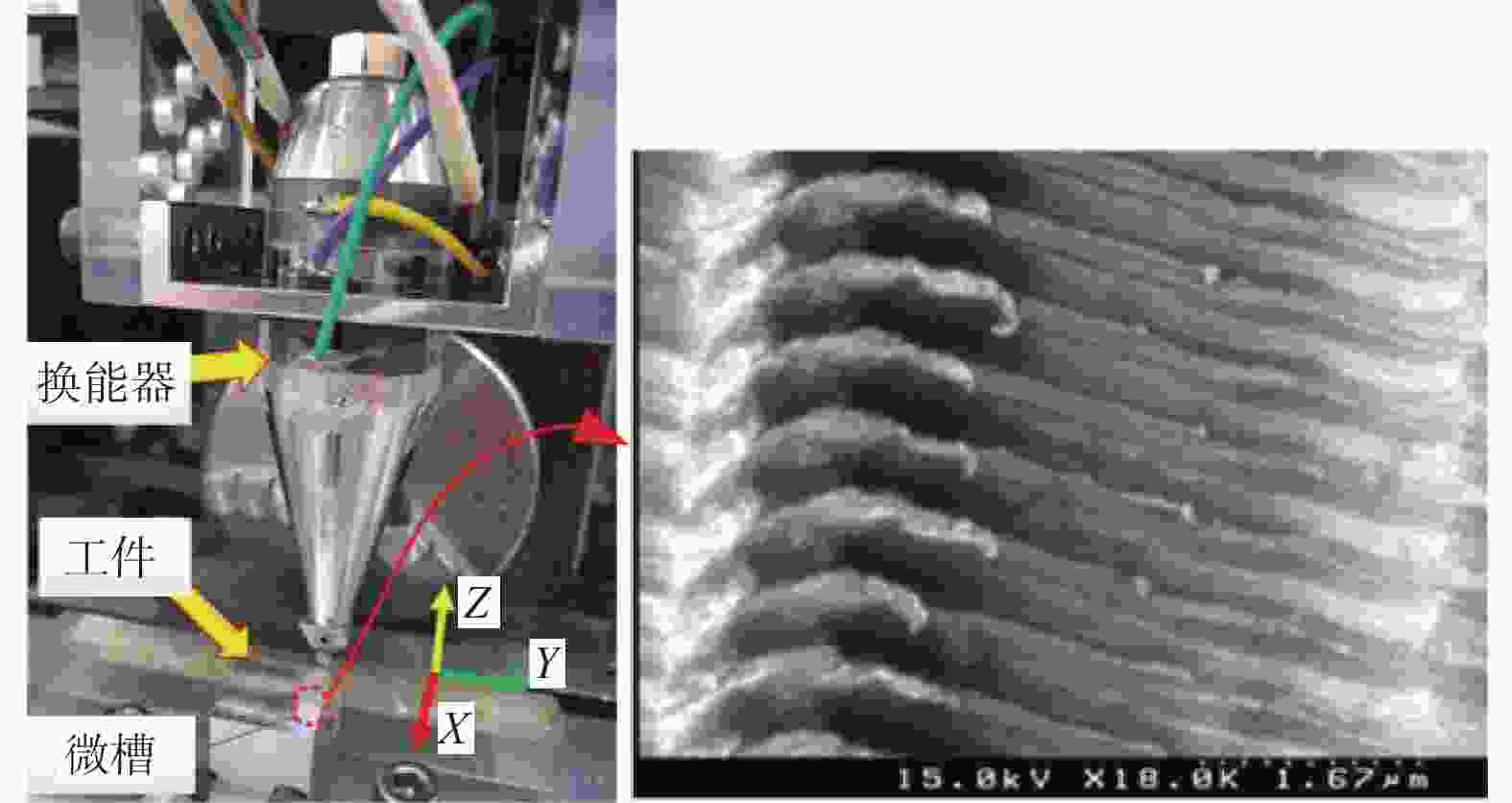

|

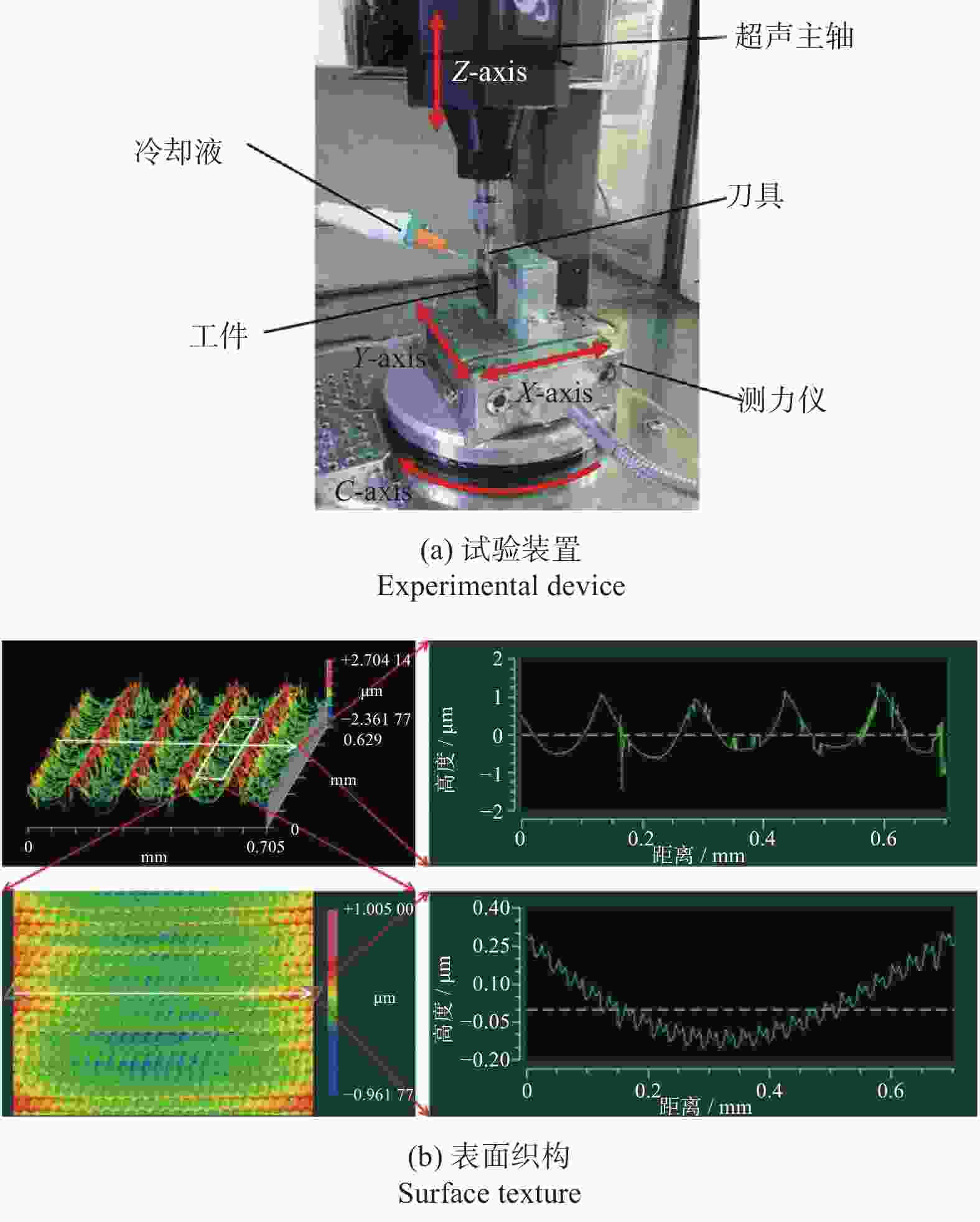

| [20] |

高国富, 浮宗霞, 王毅, 等. Ti-Al系金属间化合物精密加工研究进展 [J]. 稀有金属材料与工程,2021,50(5):1867-1882.GAO Guofu, FU Zongxia, WANG Yi, et al. Research progress on precision machining of ti-al intermetallic compounds [J]. Rare Metal Materials and Engineering,2021,50(5):1867-1882.

|

| [21] |

GRECO A, RAPHAELSON S, EHMANN K, et al. Surface texturing of tribological interfaces using the vibromechanical texturing method [J]. Journal of Manufacturing Science and Engineering-Transactions of the SAME,2009,131(6):061005. doi: 10.1115/1.4000418

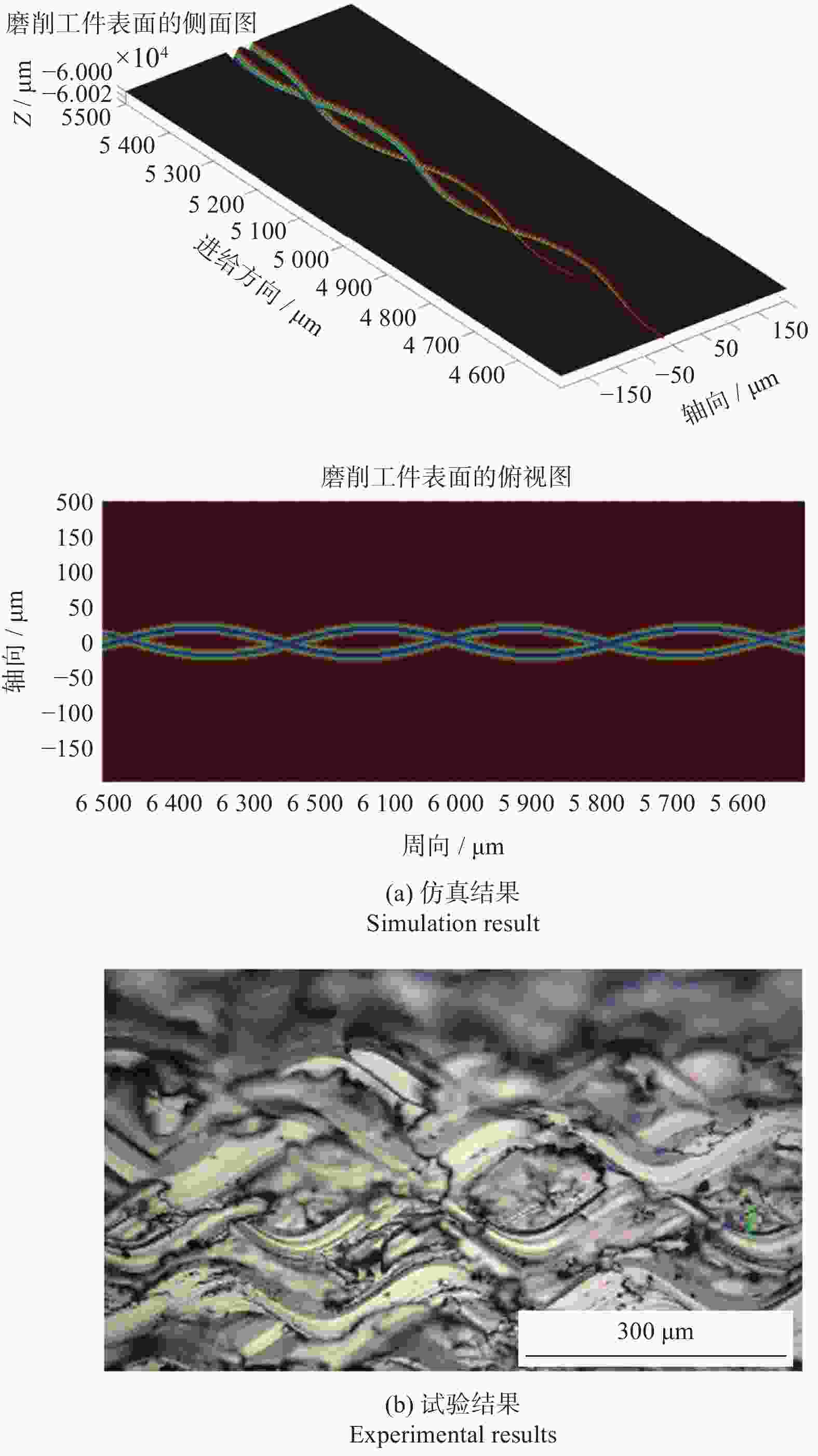

|

| [22] |

NESTLER A, SCHUBERT A. Surface properties in ultrasonic vibration assisted turning of particle reinforced aluminium matrix composites [J]. Procedia CIRP,2014,13:125-130. doi: 10.1016/j.procir.2014.04.022

|

| [23] |

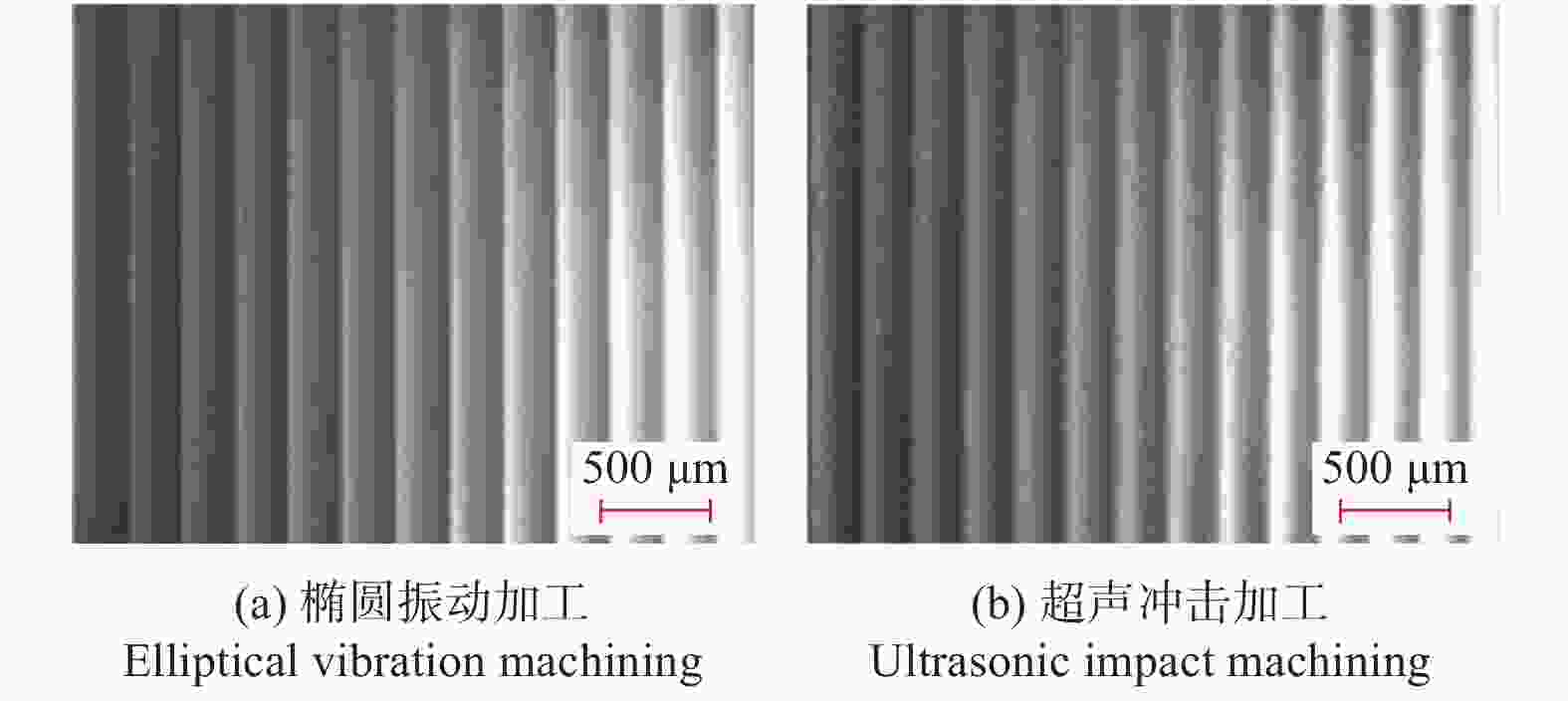

ZHANG R, STEINERT P, SCHUBERT A. Microstructuring of surfaces by two-stage vibration-assisted turning [J]. Procedia CIRP,2014,14:136-141. doi: 10.1016/j.procir.2014.03.026

|

| [24] |

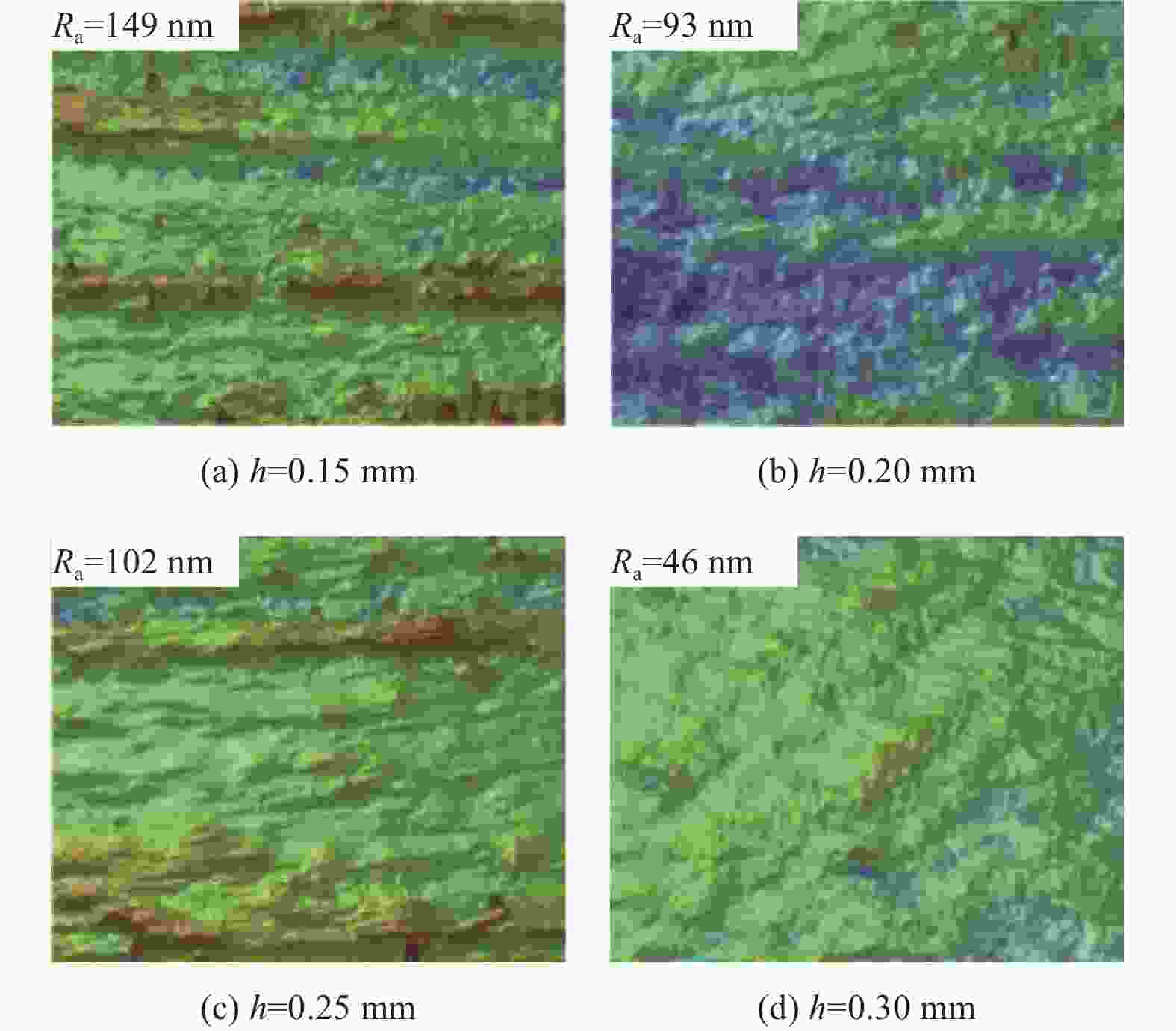

SCHUBERT A, NESTLER A, PINTERNAGEL S, et al. Influence of ultrasonic vibration assistance on the surface integrity in turning of the aluminium alloy AA2017 [J]. Materials Science and Engineering Technology,2011,42(7):658-665. doi: 10.1002/mawe.201100834

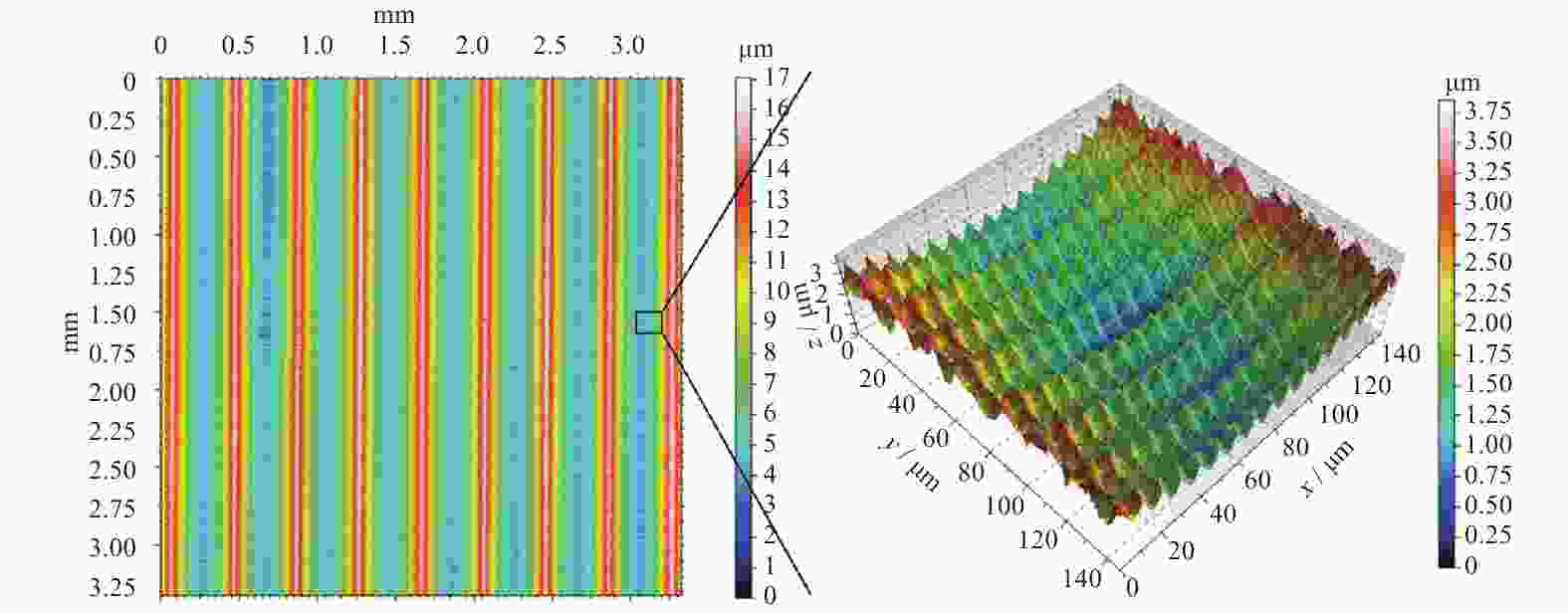

|

| [25] |

GANDHI R, SEBASTIAN D, BASU S, et al. Surfaces by vibration/modulation-assisted texturing for tribological applications [J]. International Journal of Advanced Manufacturing Technology,2016,85:909-920. doi: 10.1007/s00170-015-7968-3

|

| [26] |

李勋, 张德远. 不分离型超声椭圆振动切削试验研究 [J]. 机械工程学报,2010,46(19):177-182. doi: 10.3901/JME.2010.19.177LI Xun, ZHANG Deyuan. Experimental study on the unseparated ultrasonic elliptical vibration cutting [J]. Journal of Mechanical Engineering,2010,46(19):177-182. doi: 10.3901/JME.2010.19.177

|

| [27] |

LIU J, ZHANG D Y, QIN L G, et al. Feasibility study of the rotary ultrasonic elliptical machining of carbon fiber reinforced plastics (CFRP) [J]. International Journal of Machine Tools and Manufacture,2012,53:141-150. doi: 10.1016/j.ijmachtools.2011.10.007

|

| [28] |

MORIWAKI T, SHAMOTO E. Ultrasonic vibration elliptical cutting [J]. CIRP Annals,1995,44(1):31-34. doi: 10.1016/S0007-8506(07)62269-0

|

| [29] |

SHAMOTO E, MORIWAKI T. Ultraprecision diamond cutting of hardened steel by applying elliptical vibration cutting [J]. CIRP Annals,1999,48(1):441-444. doi: 10.1016/S0007-8506(07)63222-3

|

| [30] |

SUZUKI N, MASUDA S, HARITANI M, et al. Ultraprecision micromachining of brittle materials by applying ultrasonic elliptical vibration cutting [C]. Nagoya: IEEE, 2003.

|

| [31] |

LEE J S, LEE D W, JUNG Y H, et al. A study on micro-grooving characteristics of planar lightwave circuit and glass using ultrasonic vibration cutting [J]. Journal of Materials Processing Technology,2002,130/131:396-400. doi: 10.1016/S0924-0136(02)00740-9

|

| [32] |

SUZUKI N, HARITANI M, YANG J, et al. Elliptical vibration cutting of tungsten alloy molds for optical glass parts [J]. CIRP Annals,2007,56(1):127-130. doi: 10.1016/j.cirp.2007.05.032

|

| [33] |

ZHANG J G, SUZUKI N, WANG Y L, et al. Fundamental investigation of ultra-precision ductile machining of tungsten carbide by applying elliptical vibration cutting with single crystal diamond [J]. Journal of Materials Processing Technology,2014,214:2644-2659. doi: 10.1016/j.jmatprotec.2014.05.024

|

| [34] |

SUZUKI N, YOKOI H, SHAMOTO E. Micro/nano sculpturing of hardened steel by controlling vibration amplitude in elliptical vibration cutting [J]. Precision Engineering,2011,35:44-50. doi: 10.1016/j.precisioneng.2010.09.006

|

| [35] |

GUO P, EHMANN K F. An analysis of the surface generation mechanics of the elliptical vibration texturing process [J]. International Journal of Machine Tools and Manufacture,2013,64:85-95. doi: 10.1016/j.ijmachtools.2012.08.003

|

| [36] |

KIM G D, LOH B G. An ultrasonic elliptical vibration cutting device for micro V-groove machining: Kinematical analysis and micro V-groove machining characteristics [J]. Journal of Materials Processing technology,2007,190:181-188. doi: 10.1016/j.jmatprotec.2007.02.047

|

| [37] |

KIM G D, LOH B G. Characteristics of elliptical vibration cutting in micro-V grooving with variations in the elliptical cutting locus and excitation frequency [J]. Journal of micromechanics and microengineering,2007,18(2):025002.

|

| [38] |

KIM G D, LOH B G. Machining of micro-channels and pyramid patterns using elliptical vibration cutting [J]. The International Journal of Advanced Manufacturing Technology,2010,49:961-968. doi: 10.1007/s00170-009-2451-7

|

| [39] |

KURNIAWAN R, KISWANTO G, KO T J. Micro-dimple pattern process and orthogonal cutting force analysis of elliptical vibration texturing [J]. International Journal of Machine Tools and Manufacture,2016,106:127-140. doi: 10.1016/j.ijmachtools.2016.03.007

|

| [40] |

BREHL D E. 3-D microstructure creation using elliptical vibration-assisted machining(EUVD) [D]. Raleigh: North Carolina State University, 2014. 39: 511-514.

|

| [41] |

CHEN W Q, ZHENG L, HUO D H, et al. Surface texture formation by non-resonant vibration assisted micro milling [J]. Journal of Micromechanics and Microengineering,2018,28(2):025006. doi: 10.1088/1361-6439/aaa06f

|

| [42] |

KURNIAWAN R, KO T J. Surface topography analysis in three-dimensional elliptical vibration texturing (3D-EVT) [J]. The International Journal of Advanced Manufacturing Technology,2019,102:1601-1621. doi: 10.1007/s00170-018-03253-1

|

| [43] |

XU S L, KURIYAGAWA T, SHIMADA K, et al. Recent advances in ultrasonic-assisted machining for the fabrication of micro/nano-textured surfaces [J]. Frontiers of Mechanical Engineering,2017,12(1):33-45. doi: 10.1007/s11465-017-0422-5

|

| [44] |

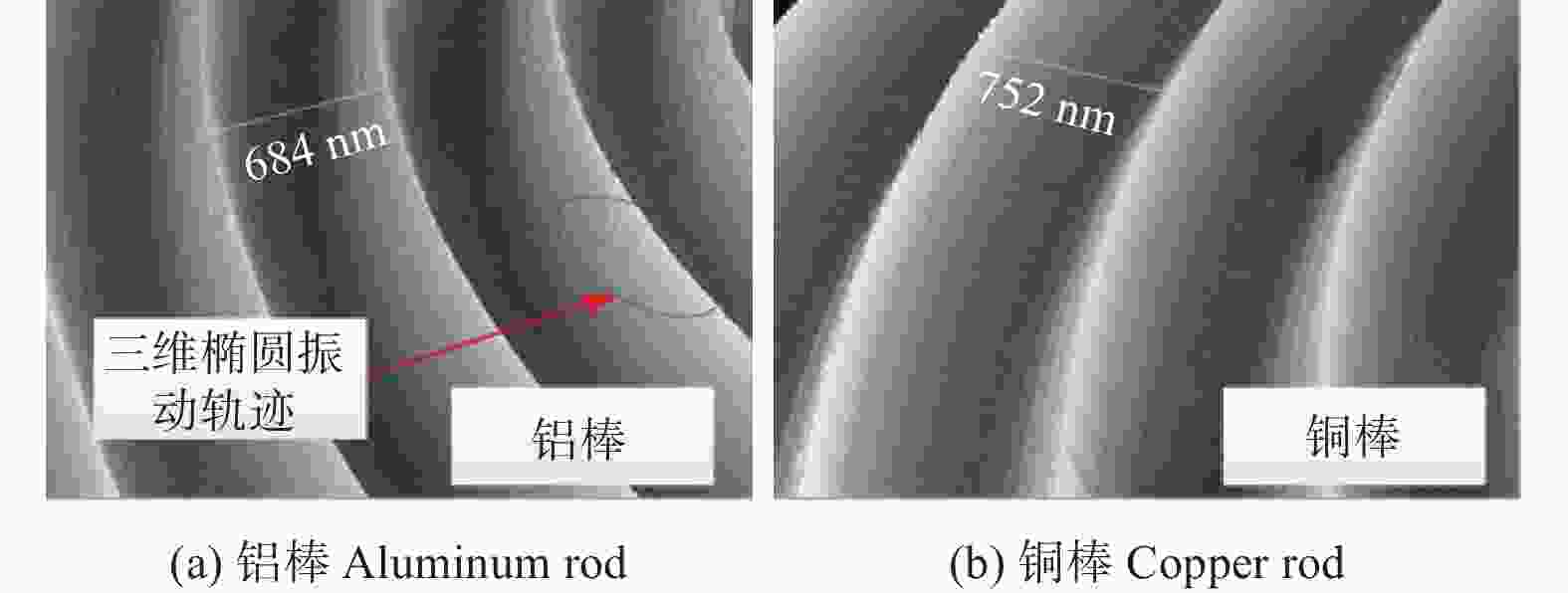

原路生, 赵波, 王毅, 等. 椭圆振动辅助车削7075铝合金表面微织构及其特性 [J]. 中国机械工程,2020,31(15):1831-1838. doi: 10.3969/j.issn.1004-132X.2020.15.010YUAN Lusheng, ZHAO Bo, WANG Yi, et al. Surface micro-texture characteristics of 7075 aluminum alloys by elliptical vibration assisted turning [J]. Chine Mechanical Engineering,2020,31(15):1831-1838. doi: 10.3969/j.issn.1004-132X.2020.15.010

|

| [45] |

王刚. 一种三维椭圆振动金刚石切削装置的研制 [D]. 长春: 吉林大学, 2012.WANG Gang. Development of a three-dimensional elliptical vibration assisted diamond cutting apparatus [D]. Changchun: Jilin University, 2012.

|

| [46] |

刘培会. 一种三维椭圆振动切削装置的研制 [D]. 长春: 吉林大学, 2013.LIU Peihui. Development of a new apparatus for three-dimensional elliptical vibration cutting [D]. Changchun: Jilin University, 2013.

|

| [47] |

宋云. 三维椭圆振动辅助切削系统研究与开发 [D]. 南京: 南京航空航天大学, 2017.SONG Yun. Research and development of 3D elliptical vibration assisted cutting system [J]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2017.

|

| [48] |

LU M M, ZHOU J K, LIN J Q, et al. Study on Ti-6Al-4V alloy machining applying the non-resonant three-dimensional elliptical vibration cutting [J]. Micromachines,2017,8(10):306. doi: 10.3390/mi8100306

|

| [49] |

LIN J, LU M, ZHOU X. Development of a non-resonant 3D elliptical vibration cutting apparatus for diamond turning [J]. Experimental Techniques,2016,40:173-183. doi: 10.1007/s40799-016-0021-0

|

| [50] |

CHEN J Z, LU M M, LIN J Q, et al. Non-resonant 3D elliptical vibration cutting induced submicron grating coloring [J]. International Journal of Precision Engineering and Manufacturing,2021,22:659-669. doi: 10.1007/s12541-021-00470-9

|

| [51] |

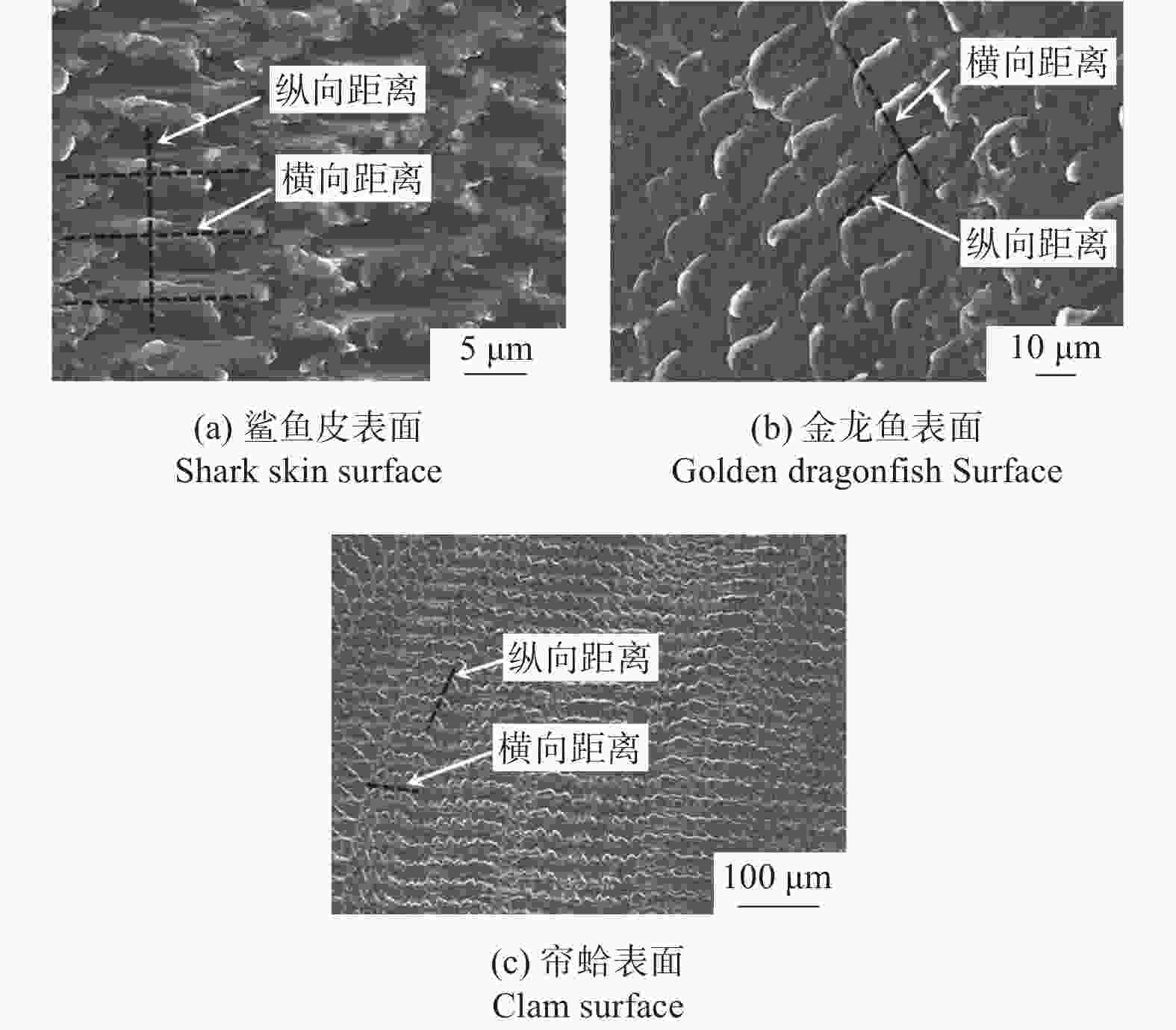

白利娟, 张建华, 陶国灿, 等. 振动辅助铣削加工仿生表面研究 [J]. 中国机械工程,2016,27(9):1229-1233, 1242. doi: 10.3969/j.issn.1004-132X.2016.09.015BAI Lijuan, ZHANG Jianhua, TAO Guocan, et al. Vibration assisted milling for bionic surface manufacturing [J]. Chine Mechanical Engineering,2016,27(9):1229-1233, 1242. doi: 10.3969/j.issn.1004-132X.2016.09.015

|

| [52] |

CHEN W Q, LU Z, XIE W, et al. Modelling and experimental investigation on textured surface generation in vibration-assisted micro-milling [J]. Journal of Materials Processing Technology,2019,266:339-350. doi: 10.1016/j.jmatprotec.2018.11.011

|

| [53] |

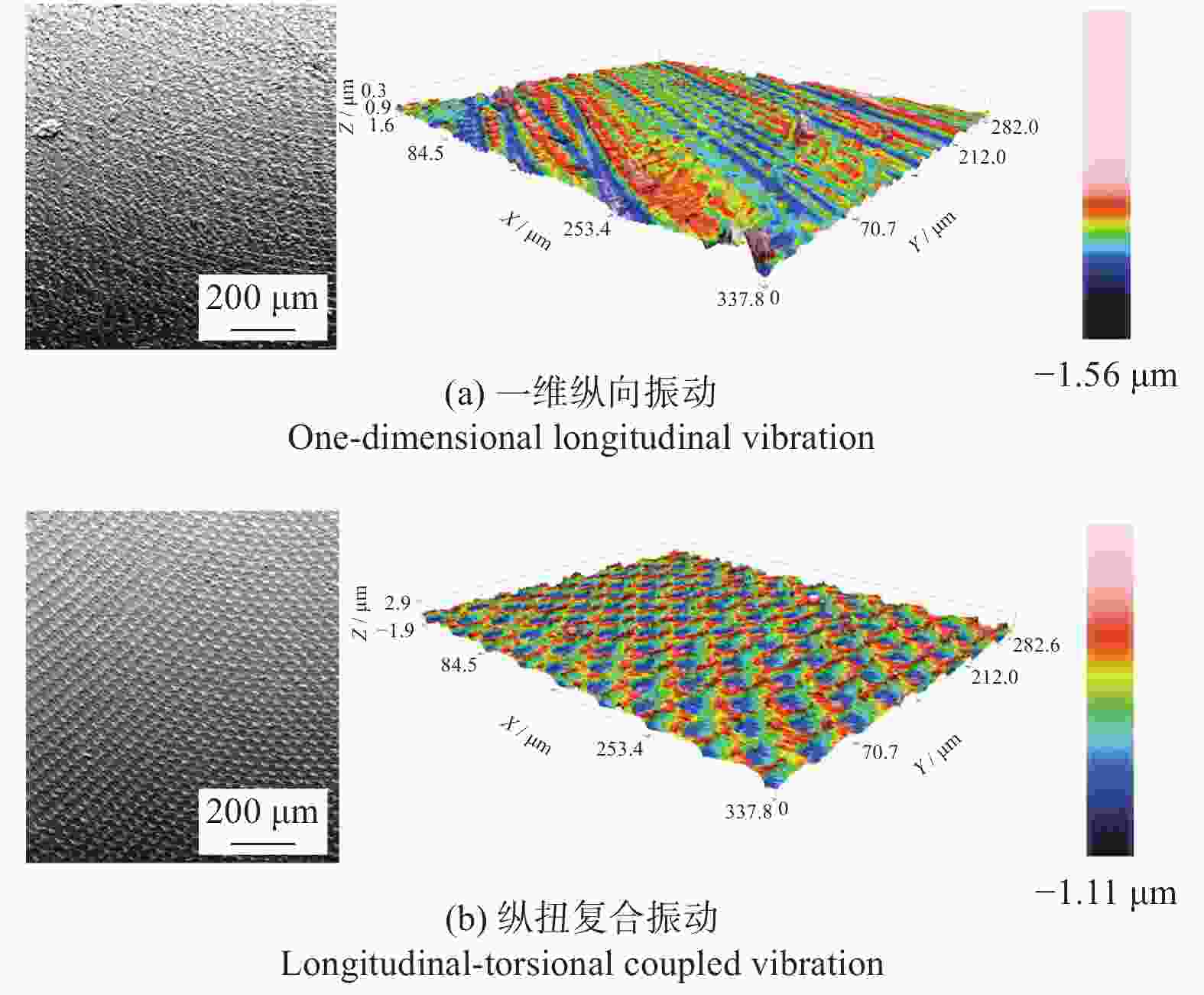

张存鹰, 赵波, 王晓博. 纵扭复合超声端面铣削表面微结构建模与试验研究 [J]. 表面技术,2019,48(10):52-63, 79. doi: 10.16490/j.cnki.issn.1001-3660.2019.10.006ZHANG Cunying, ZHAO Bo, WANG Xiaobo. Modeling and experiment of surface microstructure by longitudinal-torsional compound ultrasonic end milling [J]. Surface Technology,2019,48(10):52-63, 79. doi: 10.16490/j.cnki.issn.1001-3660.2019.10.006

|

| [54] |

PANG Y, FENG P F, WANG J J, et al. Performance analysis of the longitudinal-torsional ultrasonic milling of Ti-6Al-4V [J]. The International Journal of Advanced Manufacturing Technology,2021,113:1255-1266. doi: 10.1007/s00170-021-06682-7

|

| [55] |

袁照杰. Ti3Al金属间化合物多维超声加工切屑分离特性研究 [D]. 焦作: 河南理工大学, 2021.YUAN Zhaojie. Study on chip separation characteristics in multidimensional ultrasonic machining Ti3Al intermetallic compounds [D]. Jiaozuo: Henan Polytechnic University, 2021.

|

| [56] |

XU S L, SHIMADA K, MIZUTANI M, et al. Fabrication of hybrid micro/nano-textured surfaces using rotary ultrasonic machining with one-point diamond tool [J]. International Journal of Machine Tools and Manufacture,2014,86:12-17. doi: 10.1016/j.ijmachtools.2014.06.005

|

| [57] |

CHEN C S, TANG J Y, CHEN H F, et al. An active manufacturing method of surface micro structure based on ordered grinding wheel and ultrasonic-assisted grinding [J]. The International Journal of Advanced Manufacturing Technology,2018,97:1627-1635. doi: 10.1007/s00170-018-2044-4

|

| [58] |

JIANG J L, SUN S F, WANG D X, et al. Surface texture formation mechanism based on the ultrasonic vibration-assisted grinding process [J]. International Journal of Machine Tools and Manufacture,2020,156:10359. doi: 10.1016/j.ijmachtools.2020.103595

|

| [59] |

ZHOU W H, TANG J Y, SHAO W. Modelling of surface texture and parameters matching considering the interaction of multiple rotation cycles in ultrasonic assisted grinding [J]. International Journal of Mechanical Sciences,2020,166:105426. doi: 10.1016/j.ijmecsci.2019.105246

|

| [60] |

XU S L, SHIMADA K, MIZUTANI M, et al. Development of a novel 2D rotary ultrasonic texturing technique for fabricating tailored structures [J]. International Journal of Advanced Manufacturing Technology,2017,89:1161-1172. doi: 10.1007/s00170-016-9133-z

|

| [61] |

LIANG Z Q, WANG X B, WU Y B, et al. Experimental study on brittle-ductile transition in elliptical ultrasonic assisted grinding (EUAG) of monocrystal sapphire using single diamond abrasive grain [J]. International Journal of Machine Tools and Manufacture,2013,71:41-51. doi: 10.1016/j.ijmachtools.2013.04.004

|

| [62] |

WANG Q Y, LIANG Z Q, WANG X B, et al. Modelling and analysis of generation mechanism of micro-surface topography during elliptical ultrasonic assisted grinding [J]. Journal of Materials Processing technology,2020,279:116585. doi: 10.1016/j.jmatprotec.2019.116585

|

| [63] |

马文举. 基于纵-扭复合超声辅助的陶瓷加工机理研究 [D]. 洛阳: 河南科技大学, 2020.MA Wenju. Research on ceramic machining mechanism based on longitudinal-torsional ultrasonic assist [D]. Luoyang: Henan University of Science and Technology, 2020.

|

| [64] |

曹小建, 吴昌将, 顾镇媛, 等. 超声冲击纳米化的研究现状与进展 [J]. 表面技术,2019,48(8):113-121. doi: 10.16490/j.cnki.issn.1001-3660.2019.08.015CAO Xiaojian, WU Changjiang, GU Zhenyuan, et al. Research status and progress on ultrasonic impact nanocrystallization [J]. Surface Technology,2019,48(8):113-121. doi: 10.16490/j.cnki.issn.1001-3660.2019.08.015

|

| [65] |

赵波, 姜燕, 别文博. 超声滚压技术在表面强化中的研究与应用进展 [J]. 航空学报,2020,41(10):023685. doi: 10.7527/S1000-6893.2020.23685ZHAO Bo, JIANG Yan, BIE Wenbo. Ultrasonic rolling technology in surface strengthening: Progress in research and applications [J]. Acta Aeronautica et Astronautica Sinica,2020,41(10):023685. doi: 10.7527/S1000-6893.2020.23685

|

| [66] |

LI L, KIM M, LEE S, et al. Influence of multiple ultrasonic impact treatments on surface roughness and wear performance of SUS301 steel [J]. Surface and Coatings Technology,2016,307:517-524. doi: 10.1016/j.surfcoat.2016.09.023

|

| [67] |

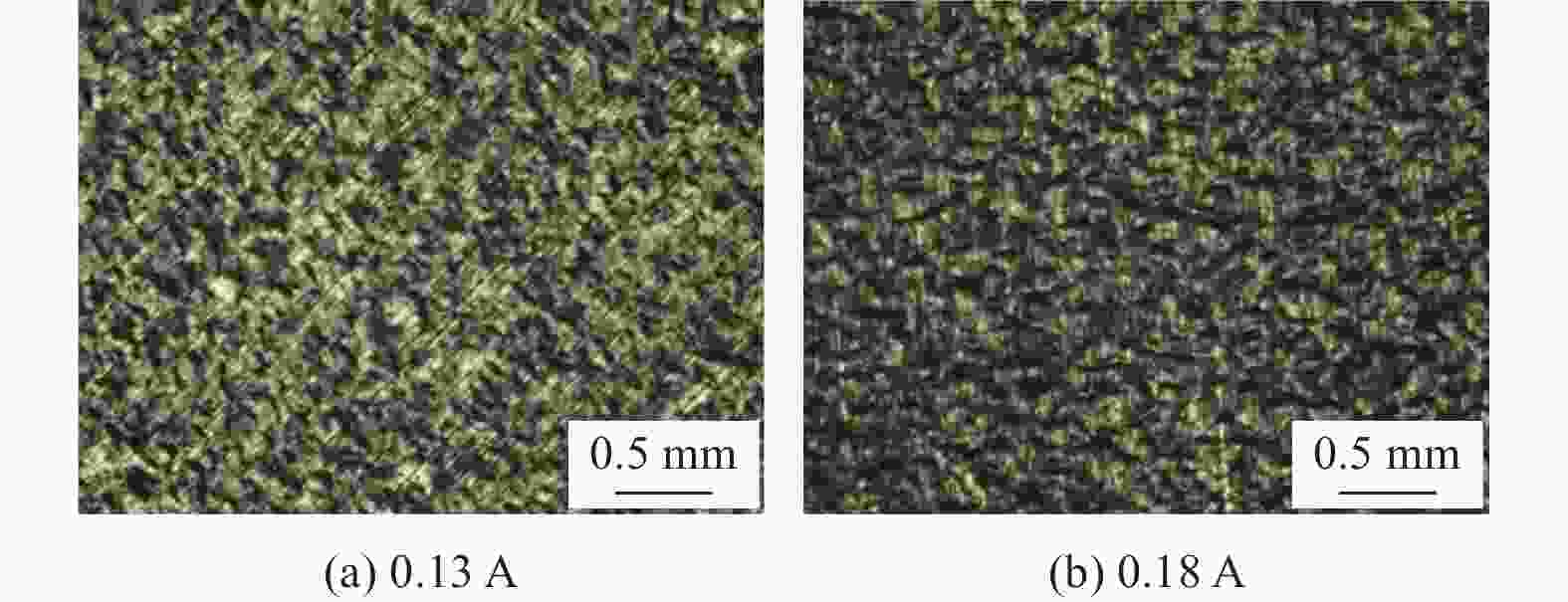

马嘉明, 郑建明, 刘驰, 等. 超声振动冲击表面织构方法及试验研究 [J]. 兵器材料科学与工程,2020,43(1):62-67. doi: 10.14024/j.cnki.1004-244x.20191021.001MA Jiaming, ZHENG Jianming, LIU Chi, et al. Ultrasonic vibration impact surface texture method and experimental study [J]. Ordnance Material Science and Engineering,2020,43(1):62-67. doi: 10.14024/j.cnki.1004-244x.20191021.001

|

| [68] |

胡王杰. 基于超声冲击的不锈钢微织构制备装置研制与实验研究 [D]. 哈尔滨: 哈尔滨工业大学, 2020.HU Wangjie. Device development and experimental study of stainless steel microtexture manufacturing by ultrasonic impact [D]. Harbin: Harbin Institute of Technology, 2020.

|

| [69] |

李礼, 朱有利, 吕光义. 超声深滚降低 TC4 钛合金表面粗糙度和修复表面损伤的作用 [J]. 稀有金属材料与工程,2009,38(2):339-342. doi: 10.3321/j.issn:1002-185X.2009.02.034LI Li, ZHU Youli, LÜ Guangyi. Influence of ultrasonic deep rolling on reducing surface roughness and healing surface scar of TC4 titanium alloy [J]. Rare Metal Materials and Engineering,2009,38(2):339-342. doi: 10.3321/j.issn:1002-185X.2009.02.034

|

| [70] |

赵建, 王兵, 刘战强. 旋转超声滚压加工中的滚压力与滚压深度及表面形貌研究 [J]. 兵工学报,2016,37(4):696-704. doi: 10.3969/j.issn.1000-1093.2016.04.018ZHAO Jian, WANG Bing, LIU Zhanqiang. The investigation into burnishing force, burnishing depth and surface morphology in rotary ultrasonic burnishing [J]. Acta Armamentarii,2016,37(4):696-704. doi: 10.3969/j.issn.1000-1093.2016.04.018

|

| [71] |

ZHENG J X, ZHU L X, GUO Y L, et al. Modeling, simulation, and prediction of surface topography in two-dimensional ultrasonic rolling 7075 Al-alloy [J]. The International Journal of Advanced Manufacturing Technology,2021,113:309-320. doi: 10.1007/s00170-021-06638-x

|

| [72] |

盖鹏涛, 陈福龙, 尚建勤, 等. 喷丸强化对表面完整性影响的研究现状与发展 [J]. 航空制造技术,2016,20:16-21. doi: 10.16080/j.issn1671-833x.2016.20.016GAI Pengtao, CHEN Fulong, SHANG Jianqin, et al. Recent situation and development trend of shot peening on surface integrity [J]. Aeronautical Manufacturing Technology,2016,20:16-21. doi: 10.16080/j.issn1671-833x.2016.20.016

|

| [73] |

MAAWAD E, SANO Y, WAGNER L, et al. Investigation of laser shock peening effects on residual stress state and fatigue performance of titanium alloys [J]. Materials Science and Engineering: A,2012,536:82-91. doi: 10.1016/j.msea.2011.12.072

|

| [74] |

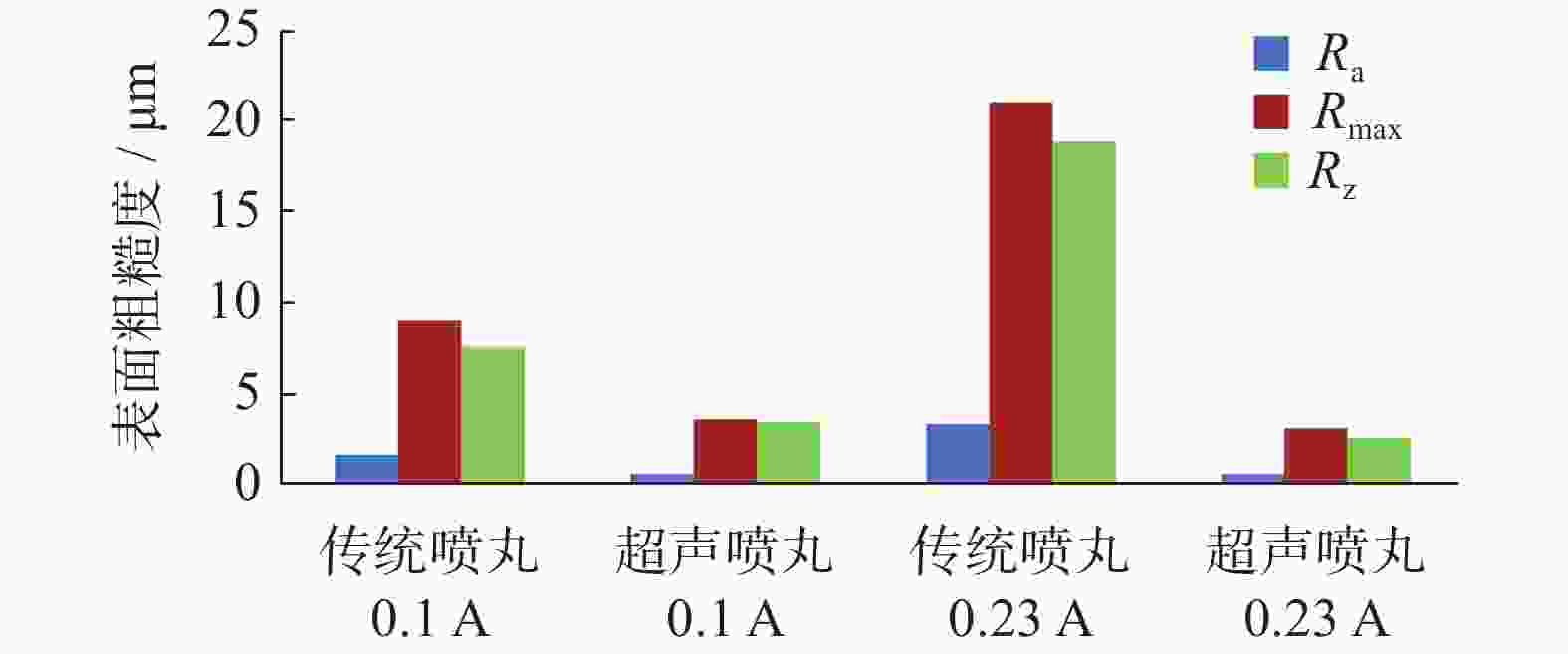

蔡晋, KIPLAGAT Collins Cherutich, 李威, 等. 超声喷丸 FGH97 粉末高温合金表面粗糙度试验与数值分析 [J]. 表面技术,2021,50(6):250-257. doi: 10.16490/j.cnki.issn.1001-3660.2021.06.028CAI Jin, KIPLAGAT Collins Cherutich, LI Wei, et al. Surface roughness numerical and test evaluation of FGH97 powder superalloy by ultrasonic shot peening [J]. Surface Technology,2021,50(6):250-257. doi: 10.16490/j.cnki.issn.1001-3660.2021.06.028

|

| [75] |

朱鹏飞, 严宏志, 陈志, 等. 齿轮齿面喷丸强化研究现状与展望 [J]. 表面技术,2020,49(4):113-131. doi: 10.16490/j.cnki.issn.1001-3660.2020.04.014ZHU Pengfei, YAN Hongzhi, CHEN Zhi, et al. Research status and prospect of shot peening of gear tooth flanks [J]. Surface Technology,2020,49(4):113-131. doi: 10.16490/j.cnki.issn.1001-3660.2020.04.014

|

| [76] |

曹腾, 路冬, 舒嵘, 等. 基于超声椭圆振动辅助车削的铝合金表面微织构仿真 [J]. 陕西师范大学学报(自然科学版),2018,46(4):50-57. doi: 10.15983/j.cnki.jsnu.2018.04.244CAO Teng, LU Dong, SHU Zheng, et al. Simulation on surface micro texture of aluminium alloy based on ultrasonic elliptical vibration cutting [J]. Journal of Shaanxi Normal University (Natural Science Edition),2018,46(4):50-57. doi: 10.15983/j.cnki.jsnu.2018.04.244

|

| [77] |

赵波. 硬脆材料超声珩磨系统及延性切削特征研究 [D]. 上海: 上海交通大学, 1999.ZHAO Bo. Study on ultrasonic honing system and feature of ductile domain cutting of hard-brittle materials [D]. Shanghai: Shanghai Jiao Tong University, 1999.

|

| [78] |

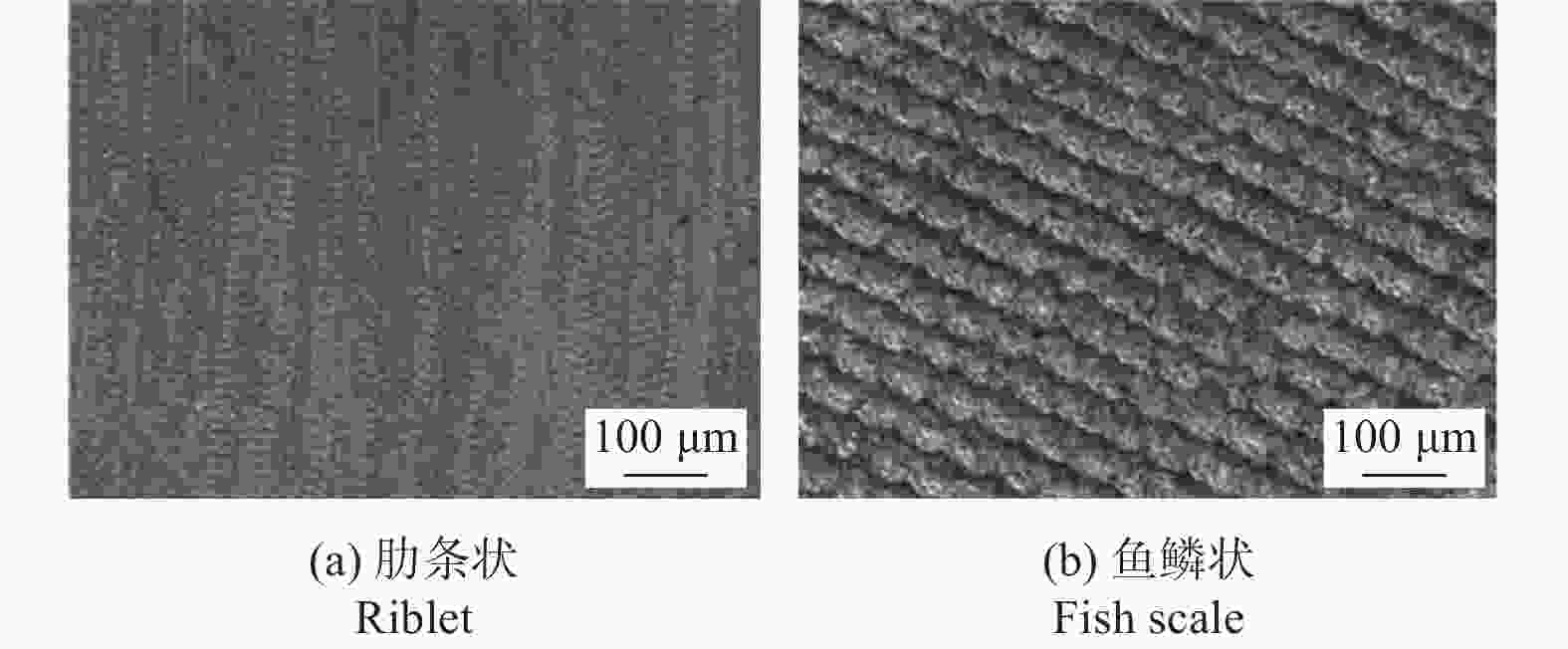

陶国灿. 超声振动辅助铣削鱼鳞状表面成形机理及表面性能研究 [D]. 济南: 山东大学, 2016.TAO Guocan. Study on the forming mechanism and surface properties of ultrasonic vibration assisted milling for squamous surfaces [D]. Jinan: Shandong University, 2016.

|

| [79] |

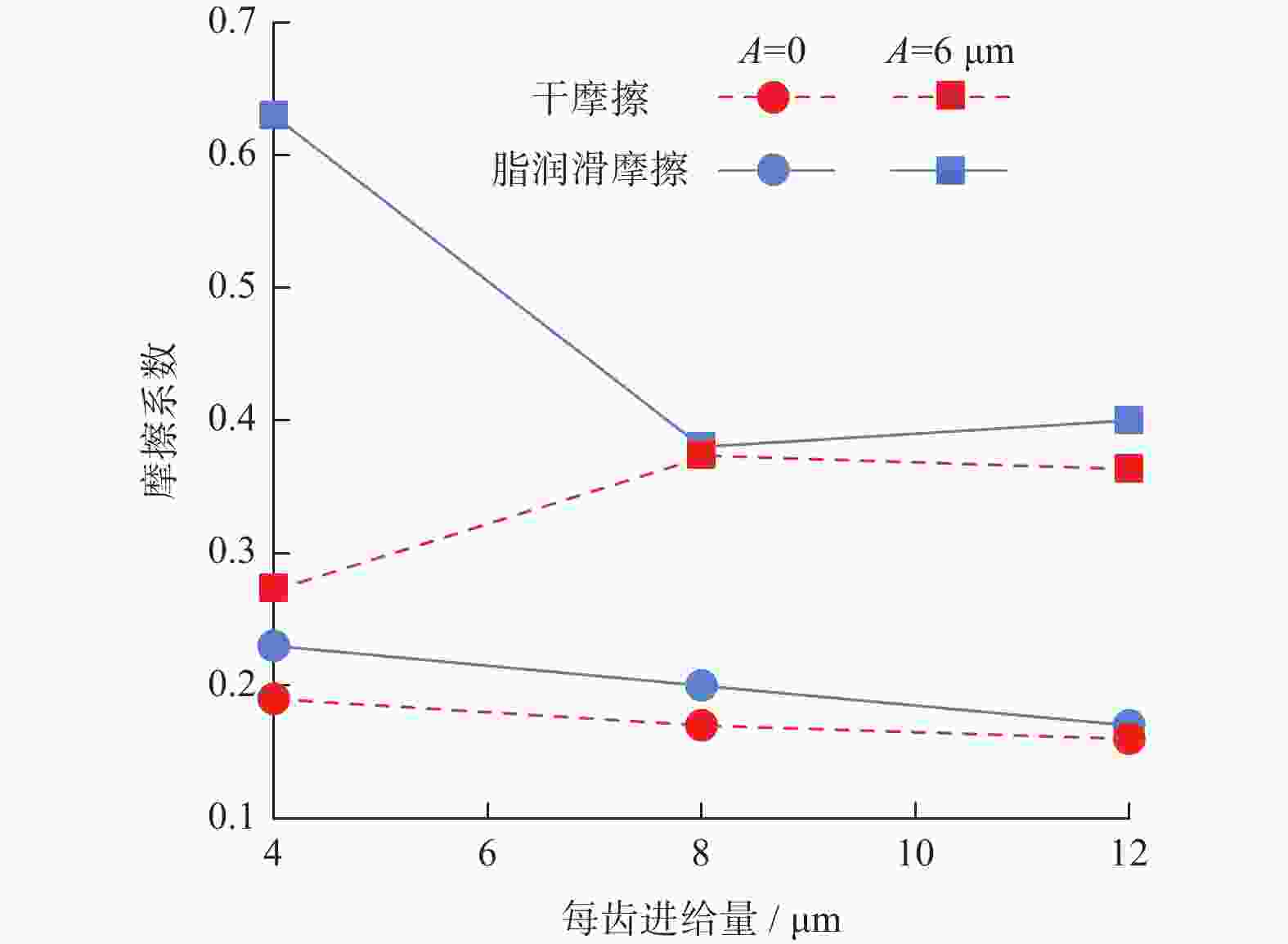

马超, 张建华, 陶国灿. 超声振动辅助铣削加工钛合金表面摩擦磨损性能研究 [J]. 表面技术,2017,46(8):115-119. doi: 10.16490/j.cnki.issn.1001-3660.2017.08.019MA Chao, ZHANG Jianhua, TAO Guocan. Wear and friction properties of titanium alloy surface subject to ultrasonic vibration assisted milling [J]. Surface Technology,2017,46(8):115-119. doi: 10.16490/j.cnki.issn.1001-3660.2017.08.019

|

| [80] |

曹腾. 超声椭圆振动辅助切削表面微织构及其摩擦性能研究 [D]. 南昌: 南昌大学, 2018.CAO Teng. Study on micro texture and friction properties of ultrasonic elliptical vibration assisted cutting surface [D]. Nanchang: Nanchang University, 2018.

|

| [81] |

ZHANG J J, ZHANG J G, ROSENKRANZ A, et al. Surface textures fabricated by laser surface texturing and diamond cutting - influence of texture depth on friction and wear [J]. Advanced Engineering Materials,2018,20(4):1700995. doi: 10.1002/adem.201700995

|

| [82] |

ZHAO C Y, WANG X B, ZHAO B, et al. Microstructure of high-performance aluminum alloy surface processed by the single-excitation same-frequency longitudinal-torsional coupled ultrasonic vibration milling [J]. Materials,2018,11(10):1975. doi: 10.3390/ma11101975

|

| [83] |

王耀宇. 摩擦副表面超声微织构加工技术研究 [D]. 太原: 中北大学, 2021.WANG Yaoyu. Research on ultrasonic micro-texture processing technology of friction pair surface [D]. Taiyuan: North University of China, 2021.

|

| [84] |

夏子文. 多维超声铣削Ti3Al金属间化合物表面微织构诱导机制研究 [D]. 焦作: 河南理工大学, 2021.XIA Ziwen. Investigation into the induction mechanism of surface micro-texture in multi-dimension ultrasonic milling Ti3Al intermetallic compound [D]. Jiaozuo: Henan Polytechnic University, 2021.

|

| [85] |

邢栋梁. 超声振动辅助铣削加工表面的摩擦学性能研究 [D]. 济南: 山东大学, 2012.XING Dongliang. Study on tribological properities of ultrasonic vibration assisted milling surfaces [D]. Jinan: Shandong University, 2012.

|

| [86] |

WEN Y Q, TANG J Y, ZHOU W, et al. Study on contact performance of ultrasonic-assisted grinding surface [J]. Ultrasonics,2019,91:193-200. doi: 10.1016/j.ultras.2018.08.009

|

| [87] |

CHEN H F, TANG J Y, SHAO W, et al. An investigation on surface functional parameters in ultrasonic-assisted grinding of soft steel [J]. International Journal of Advanced Manufacturing Technology,2018,97(5-8):2697-2702. doi: 10.1007/s00170-018-2164-x

|

| [88] |

LIU X F, WU D B, ZHANG J H. Fabrication of micro-textured surface using feed-direction ultrasonic vibration-assisted turning [J]. The International Journal of Advanced Manufacturing Technology,2018,97:3849-3857. doi: 10.1007/s00170-018-2082-y

|

| [89] |

XU S L, SHIMADA K, MIZUTANI M, et al. Analysis of machinable structures and their wettability of rotary ultrasonic texturing method [J]. Chinese Journal of Mechanical Engineering,2016,29(6):1187-1192. doi: 10.3901/CJME.2016.0910.112

|

| [90] |

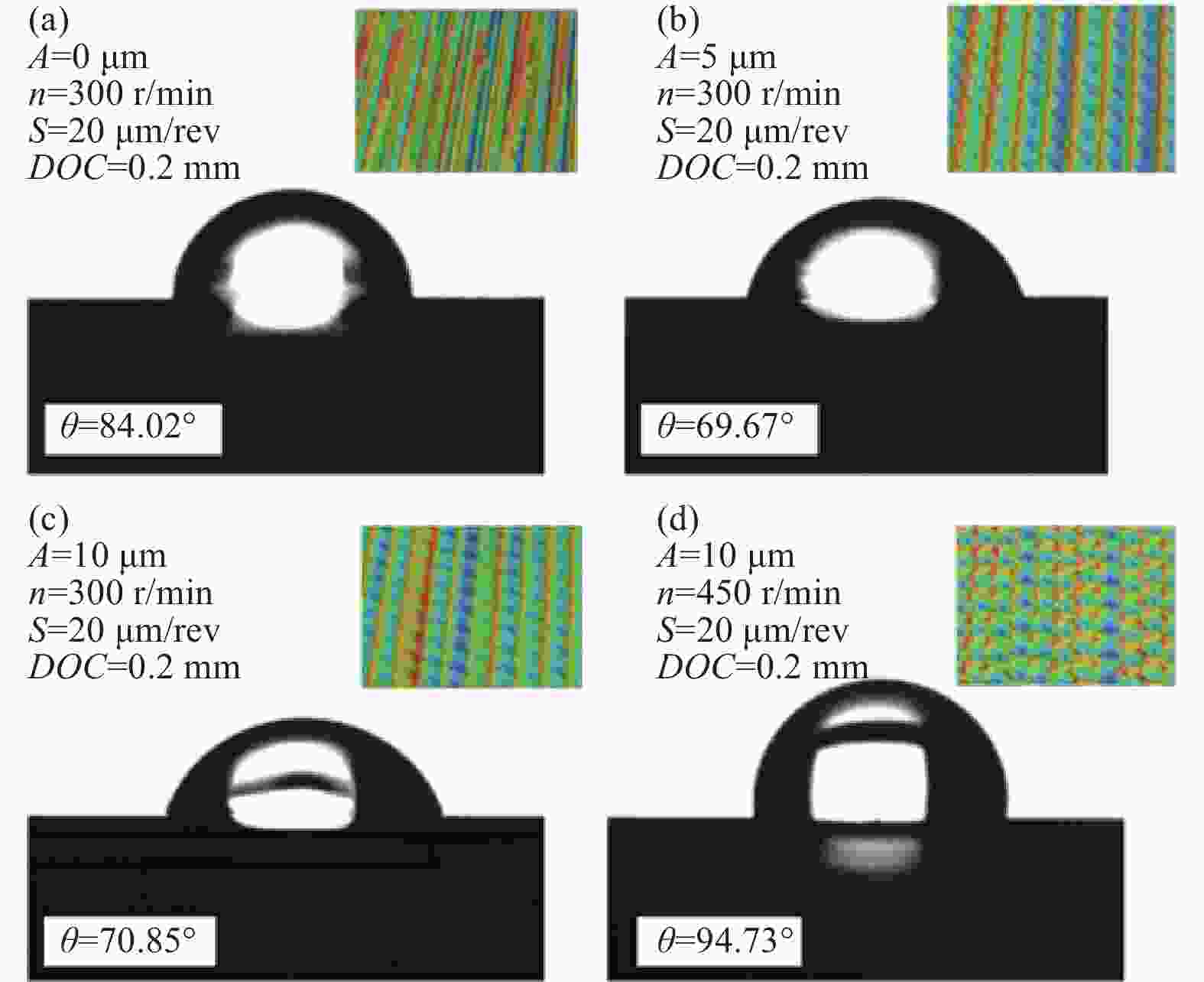

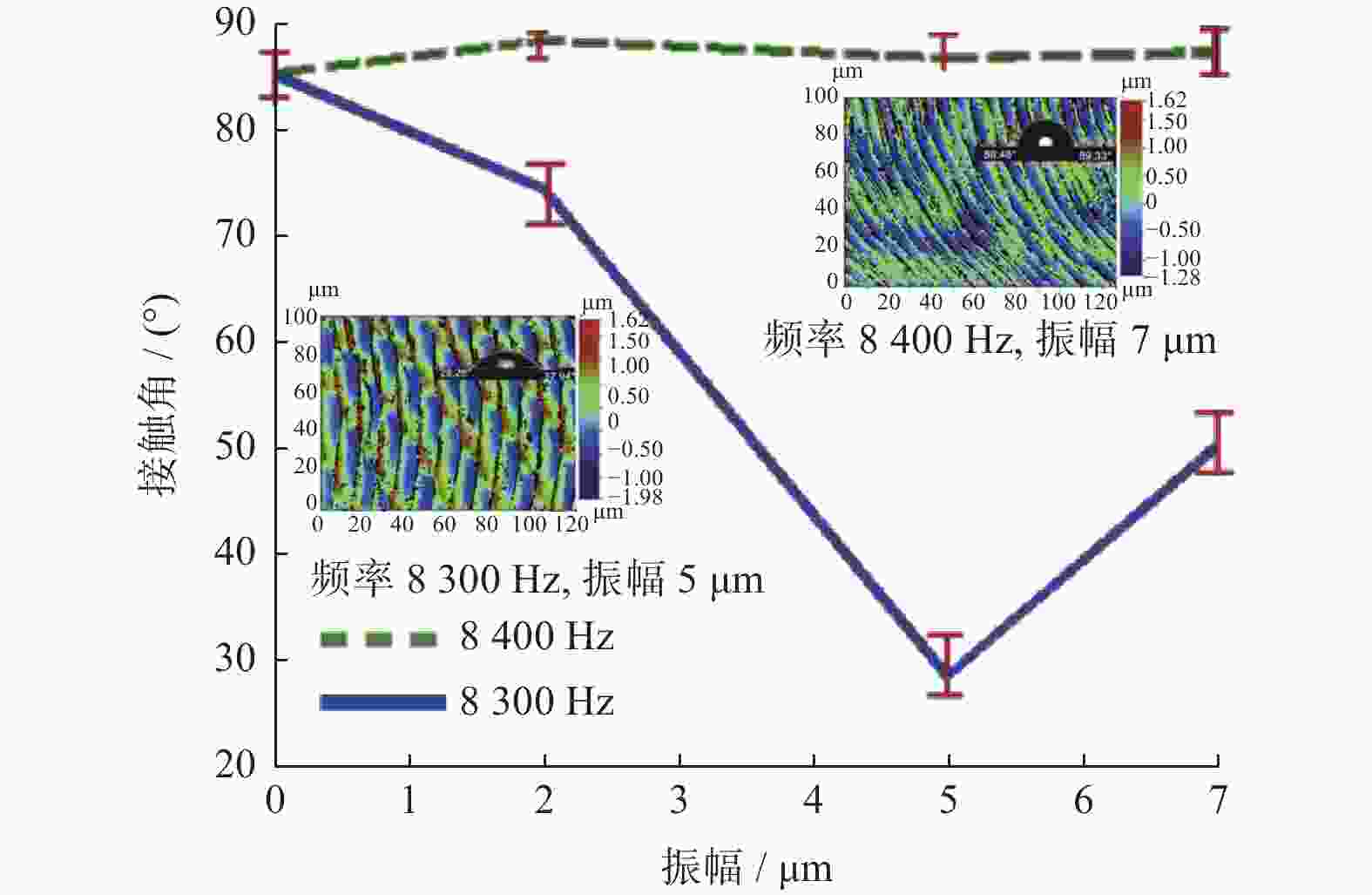

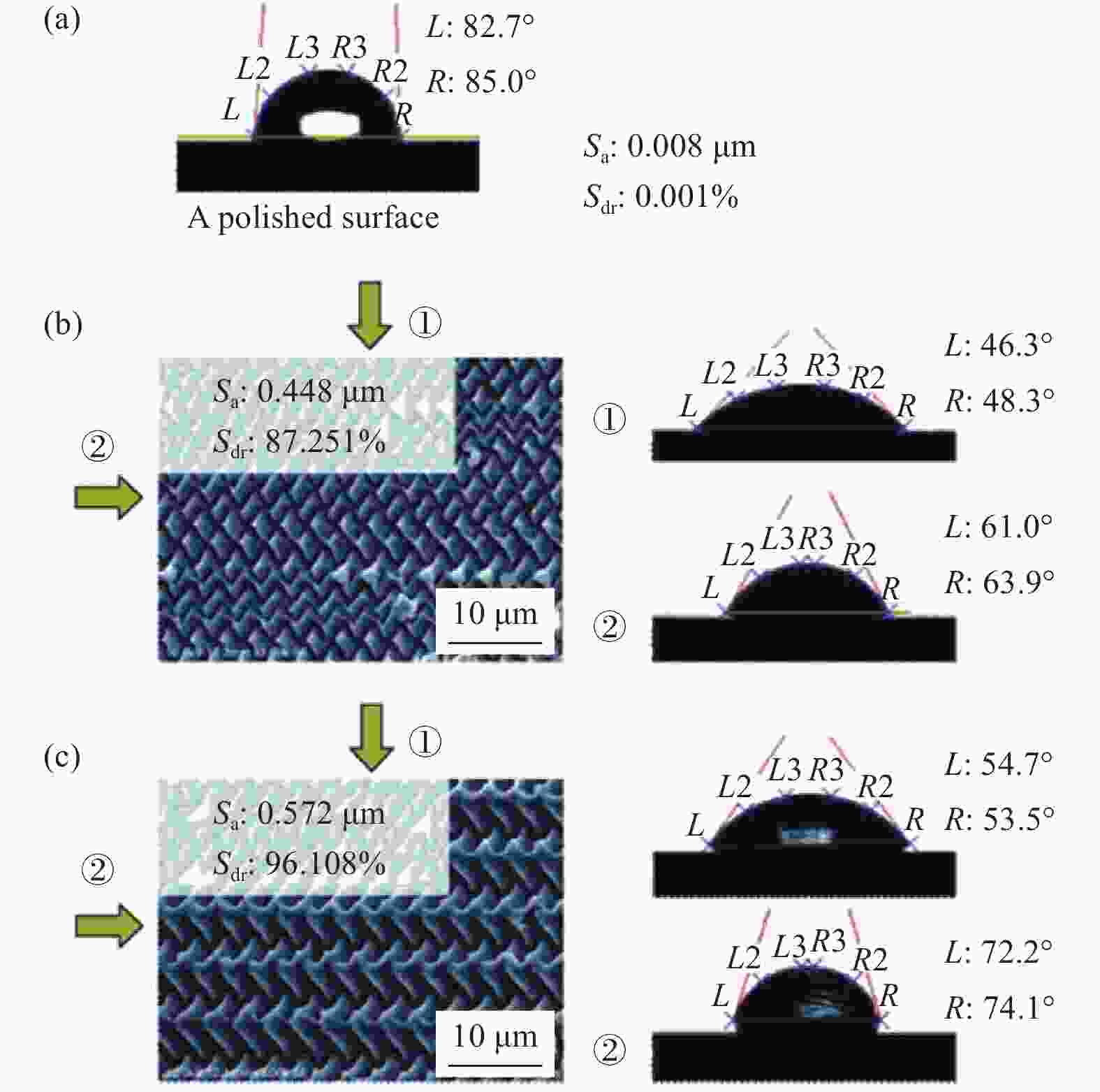

赵重阳, 陆俊宇, 王晓博, 等. 超声纵扭辅助铣削高强铝合金表面润湿性能研究 [J]. 中国机械工程,2022,33(16):1912-1918 + 1927. doi: 10.3969/j.issn.1004-132X.2022.16.004ZHAO Chongyang, LU Junyu, WANG Xiaobo, et al. Wettability of high-performance aluminum alloy surfaces machined longitudinal-torsion ultrasonic-assisted milling [J]. China Mechanical Engineering,2022,33(16):1912-1918 + 1927. doi: 10.3969/j.issn.1004-132X.2022.16.004

|

| [91] |

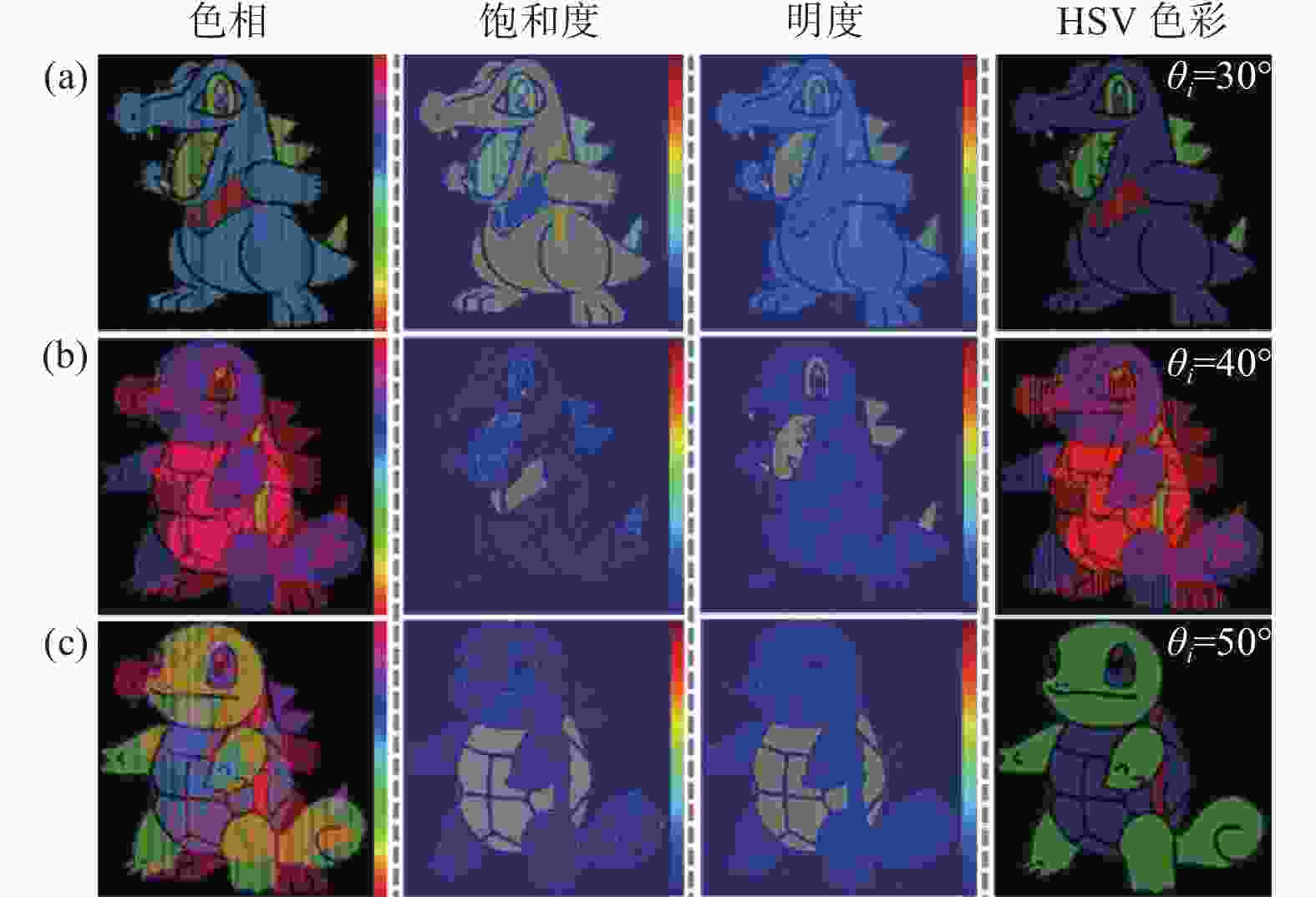

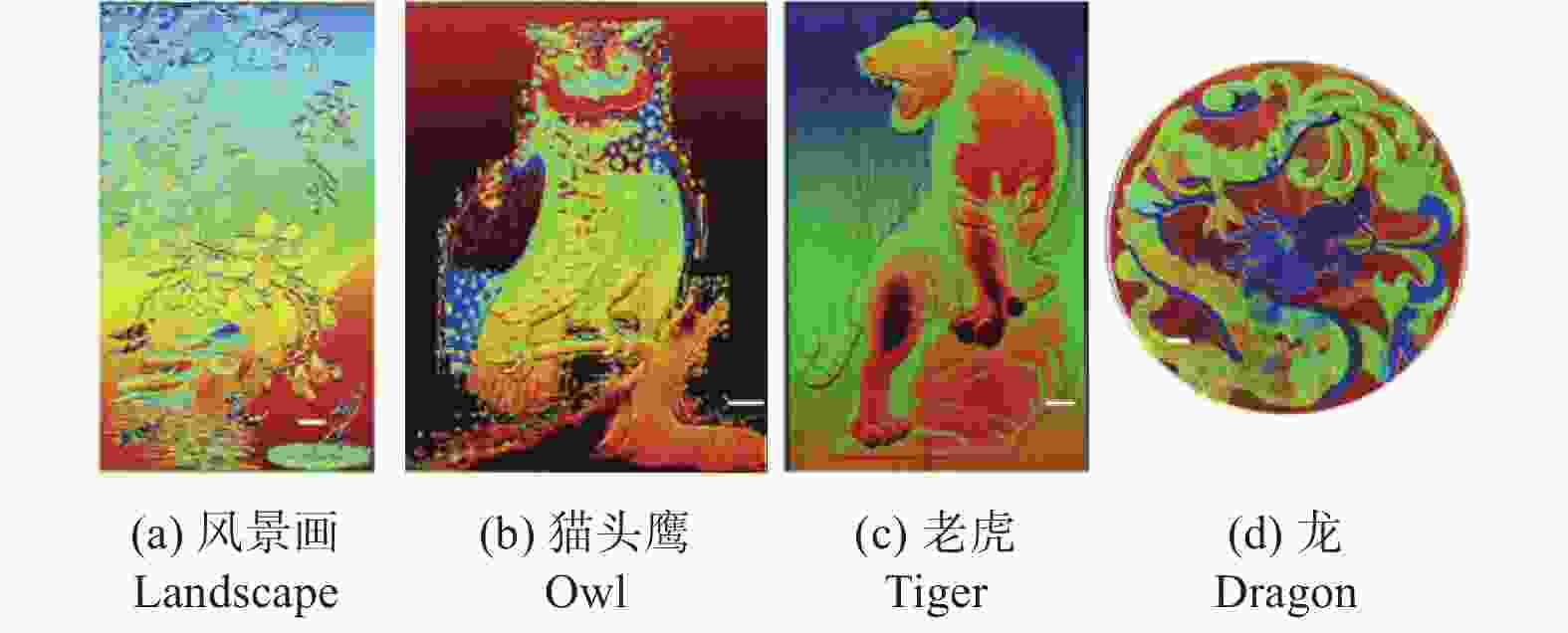

GUO P, YANG Y. A novel realization of diffractive optically variable devices using ultrasonic modulation cutting [J]. CIRP Annals-Manufacturing Technology,2019,68:575-578. doi: 10.1016/j.cirp.2019.04.014

|

| [92] |

WANG J J, WANG Y K, YANG Y. Fabrication of structurally colored basso-relievo with modulated elliptical vibration texturing [J]. Precision Engineering,2020,64:113-121. doi: 10.1016/j.precisioneng.2020.03.021

|

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS