Vitrified bond diamond grinding wheel based on hollow corundum microspheres

-

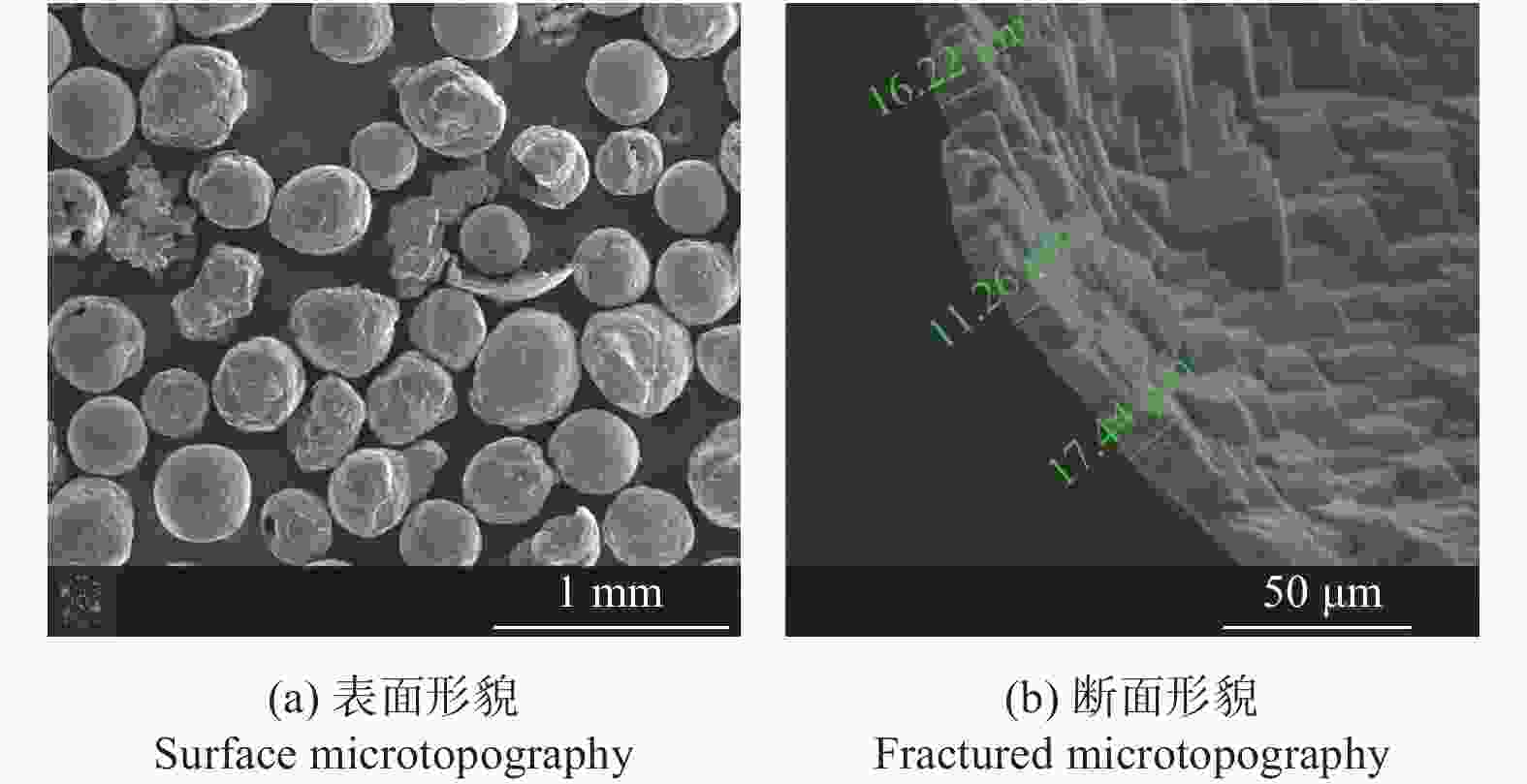

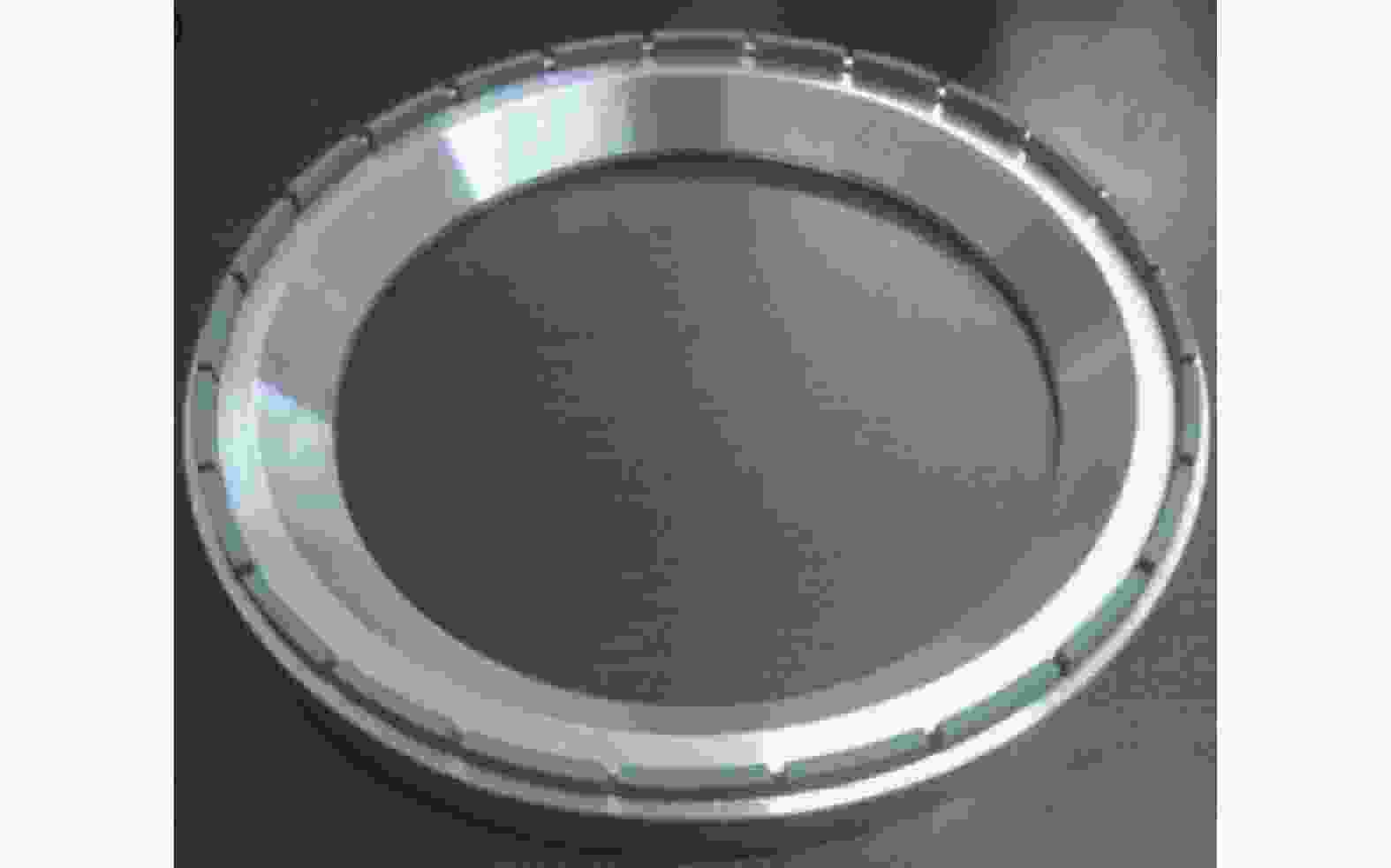

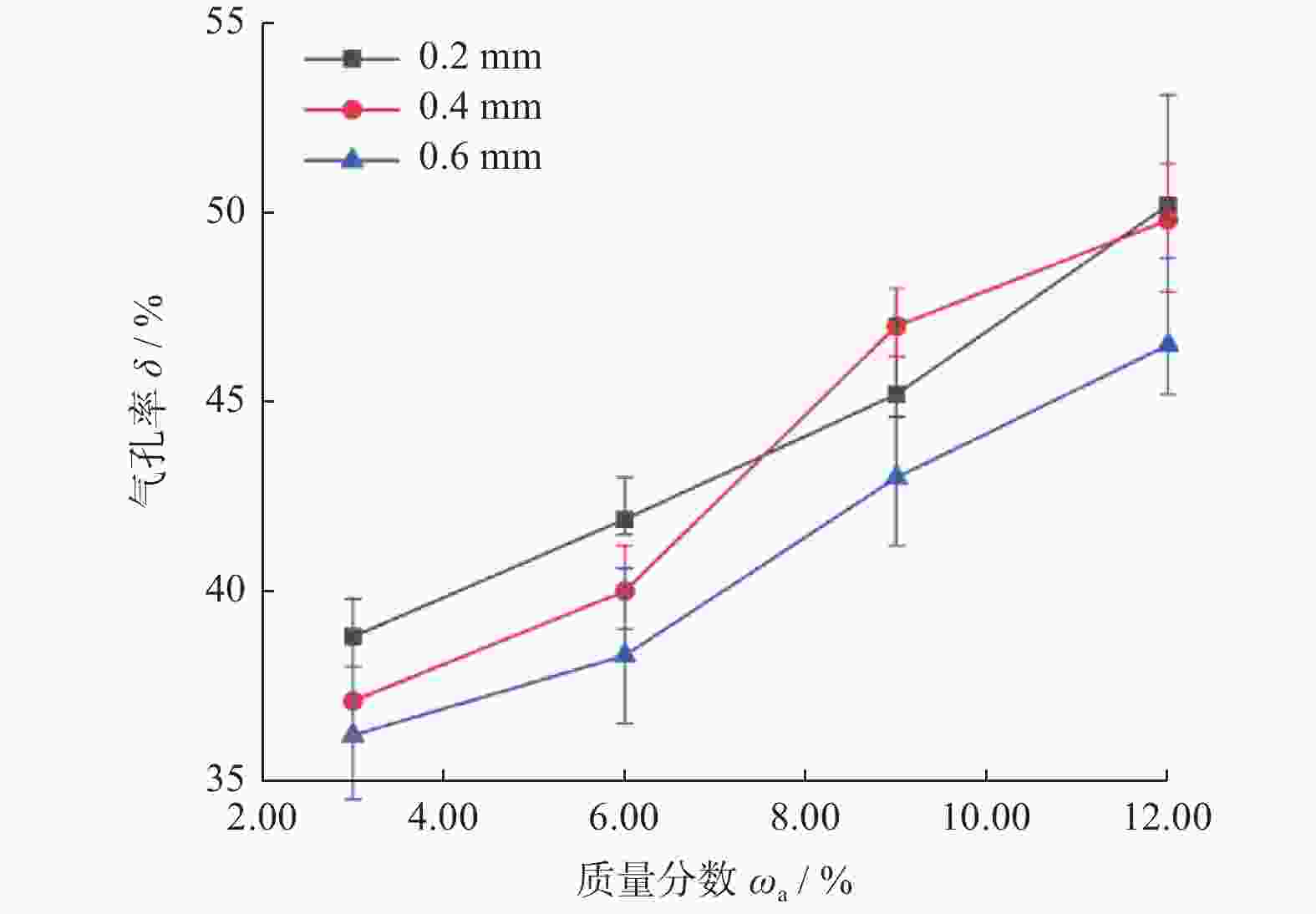

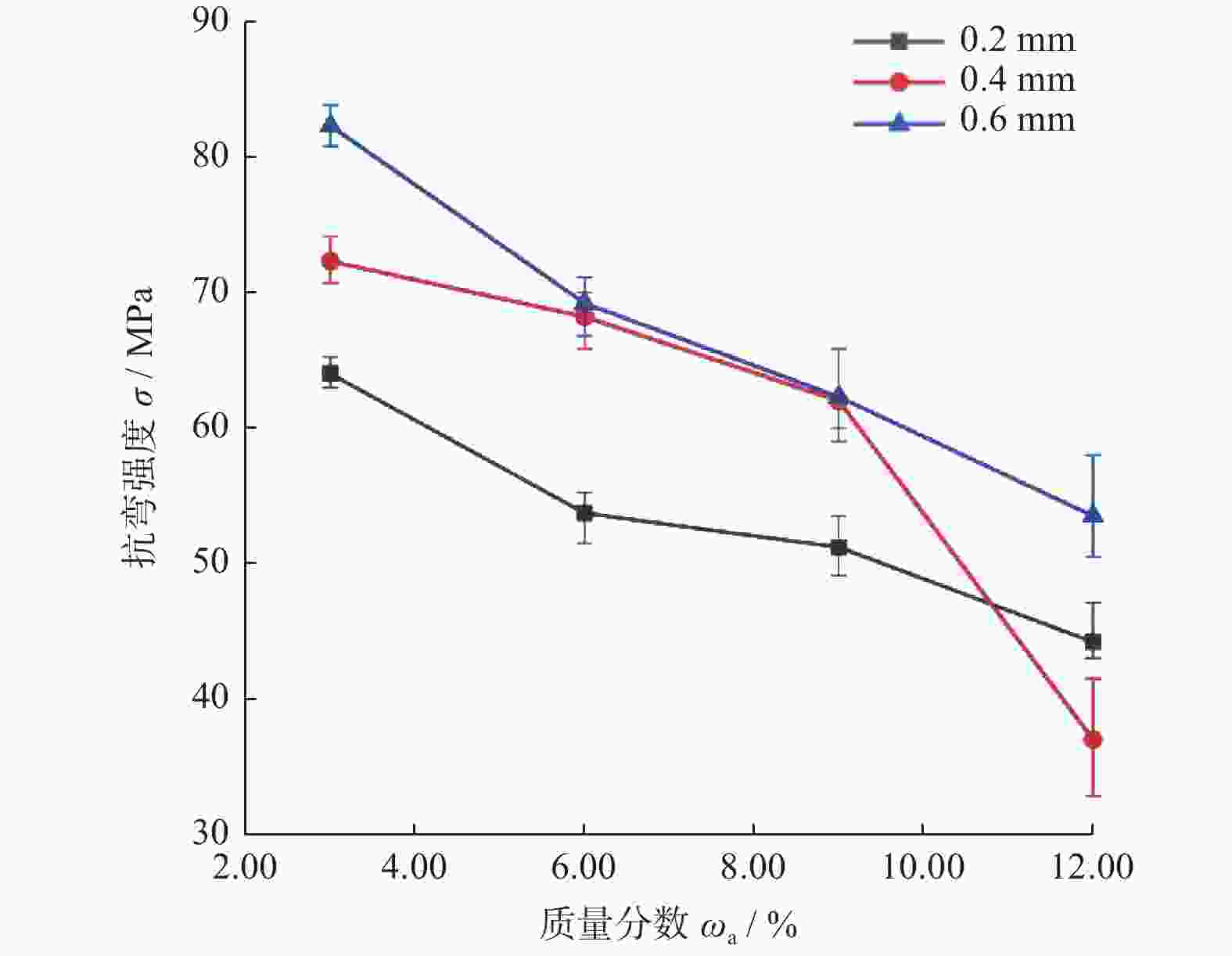

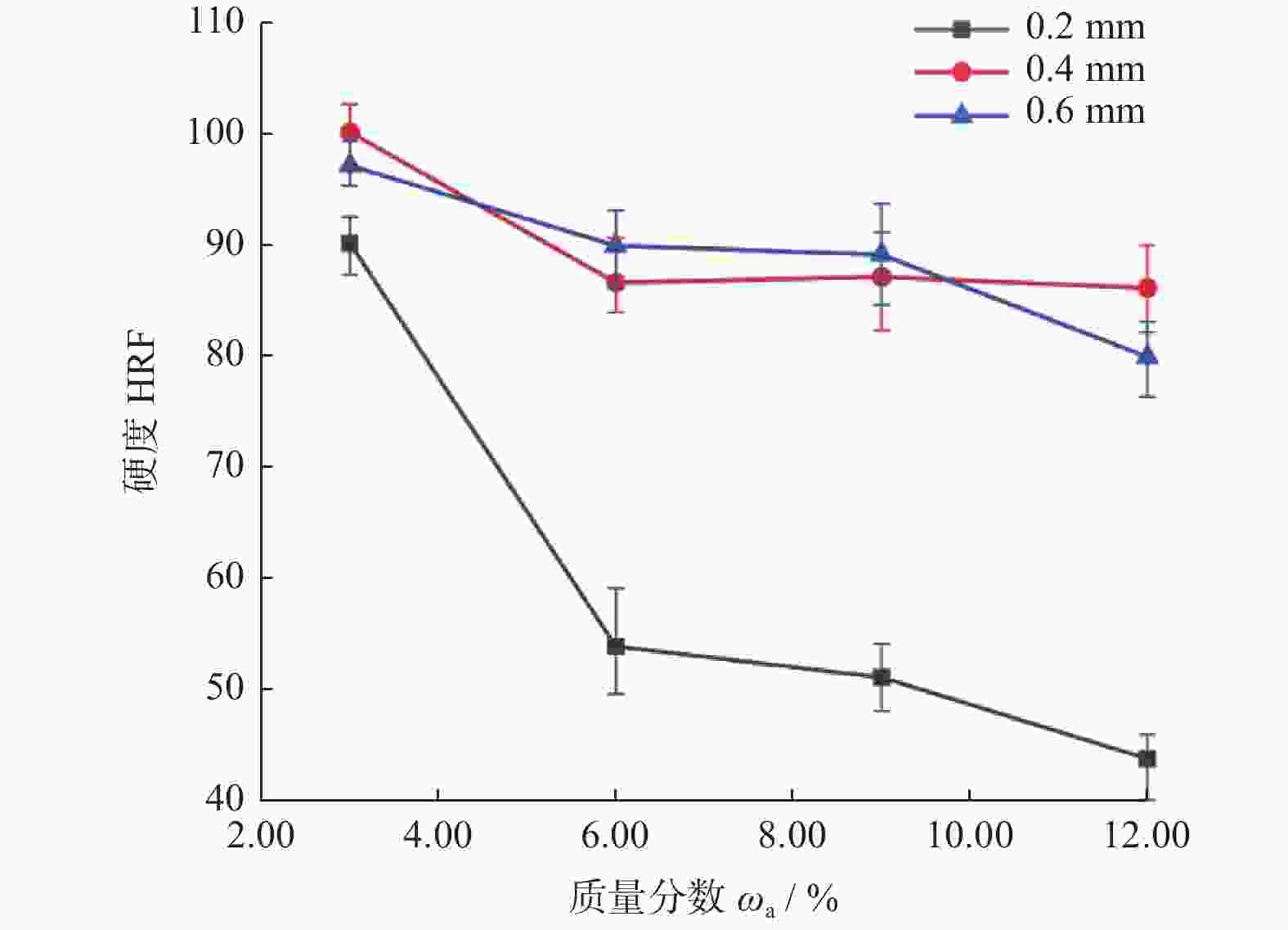

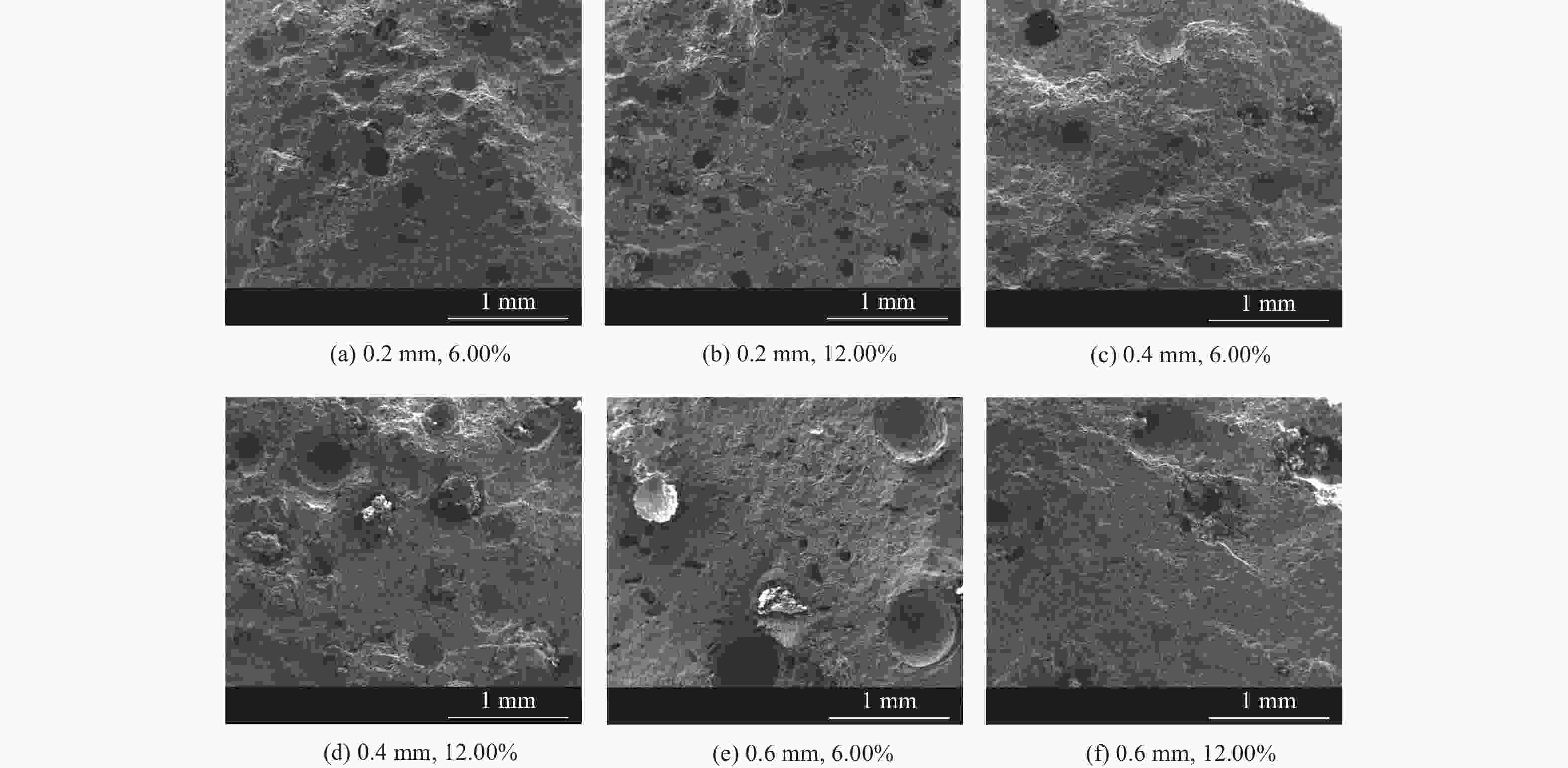

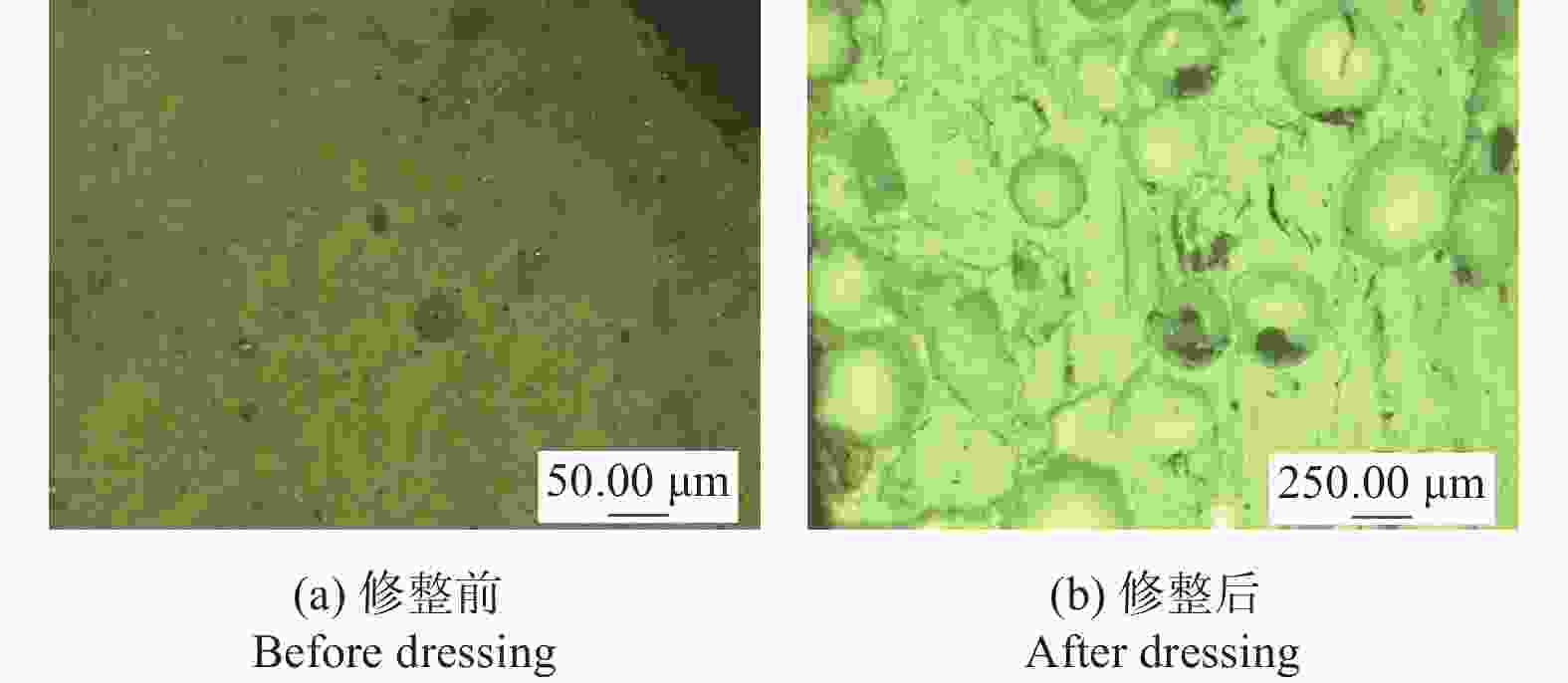

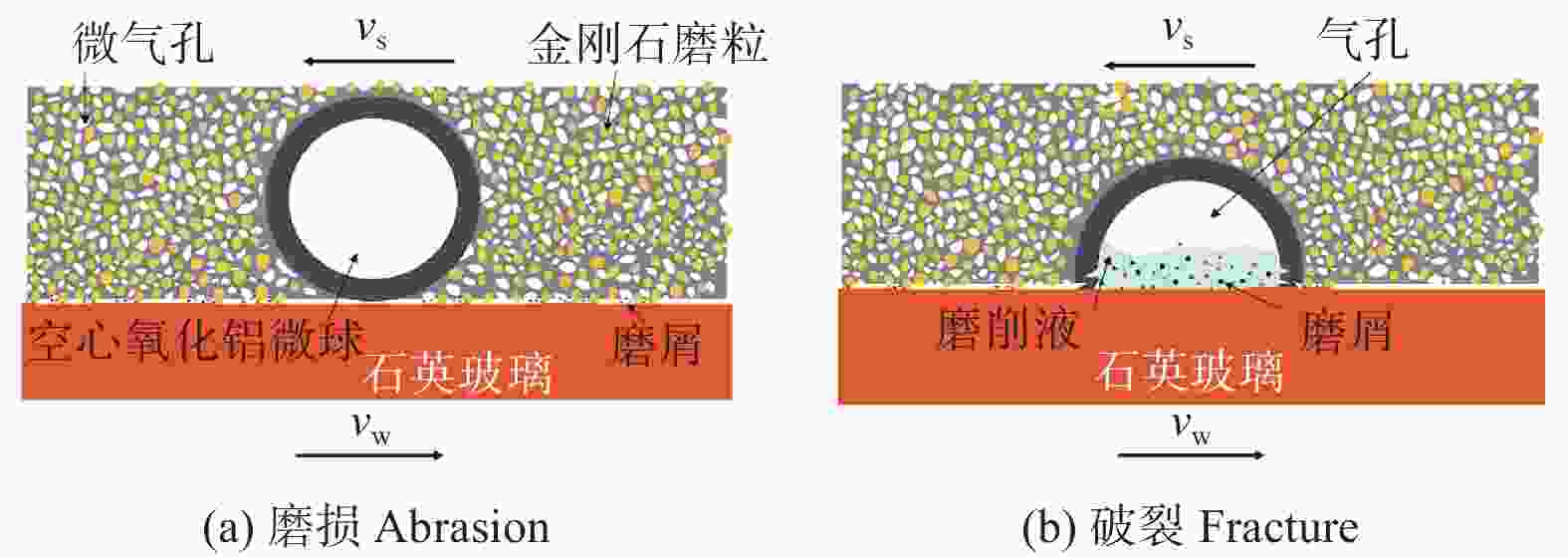

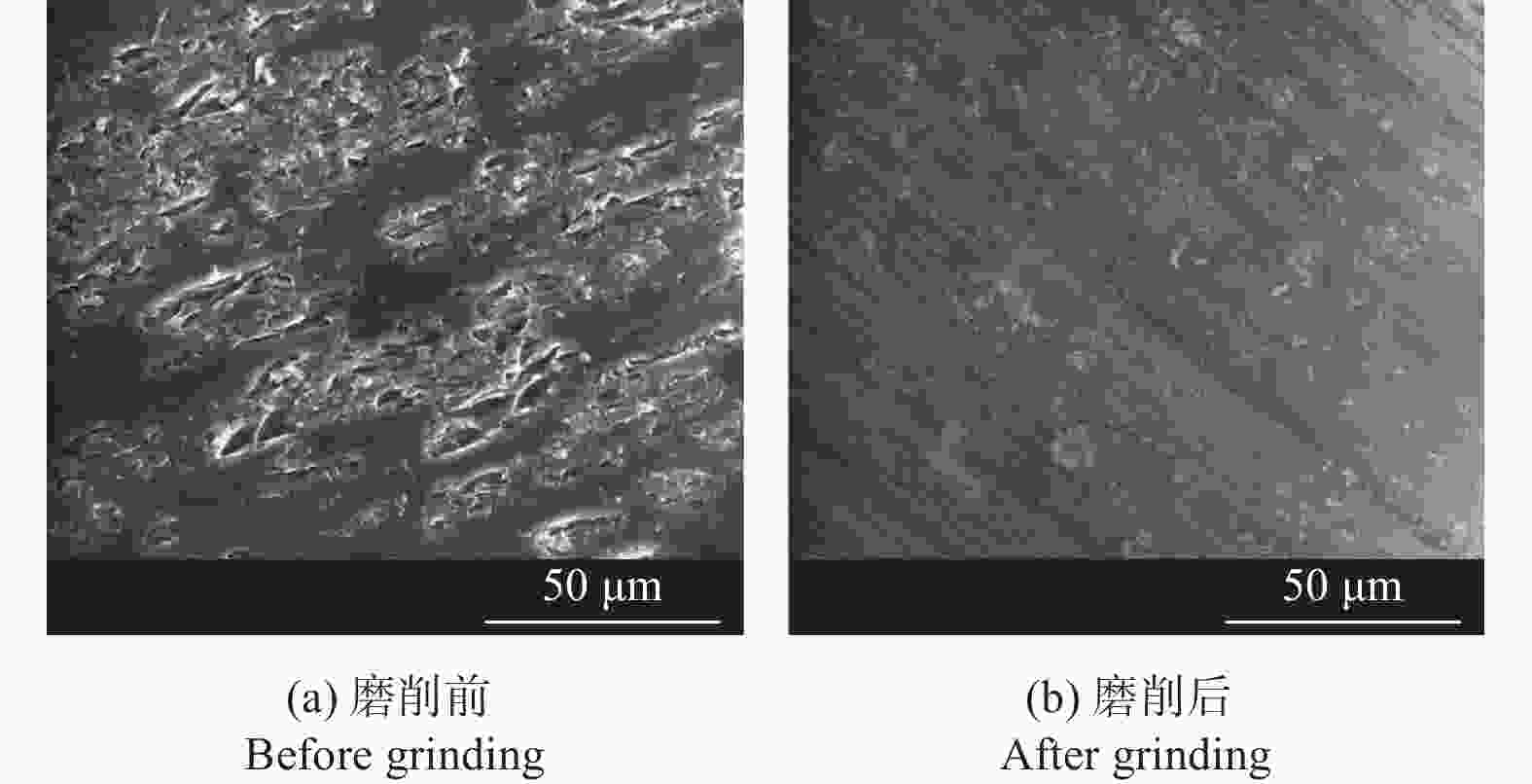

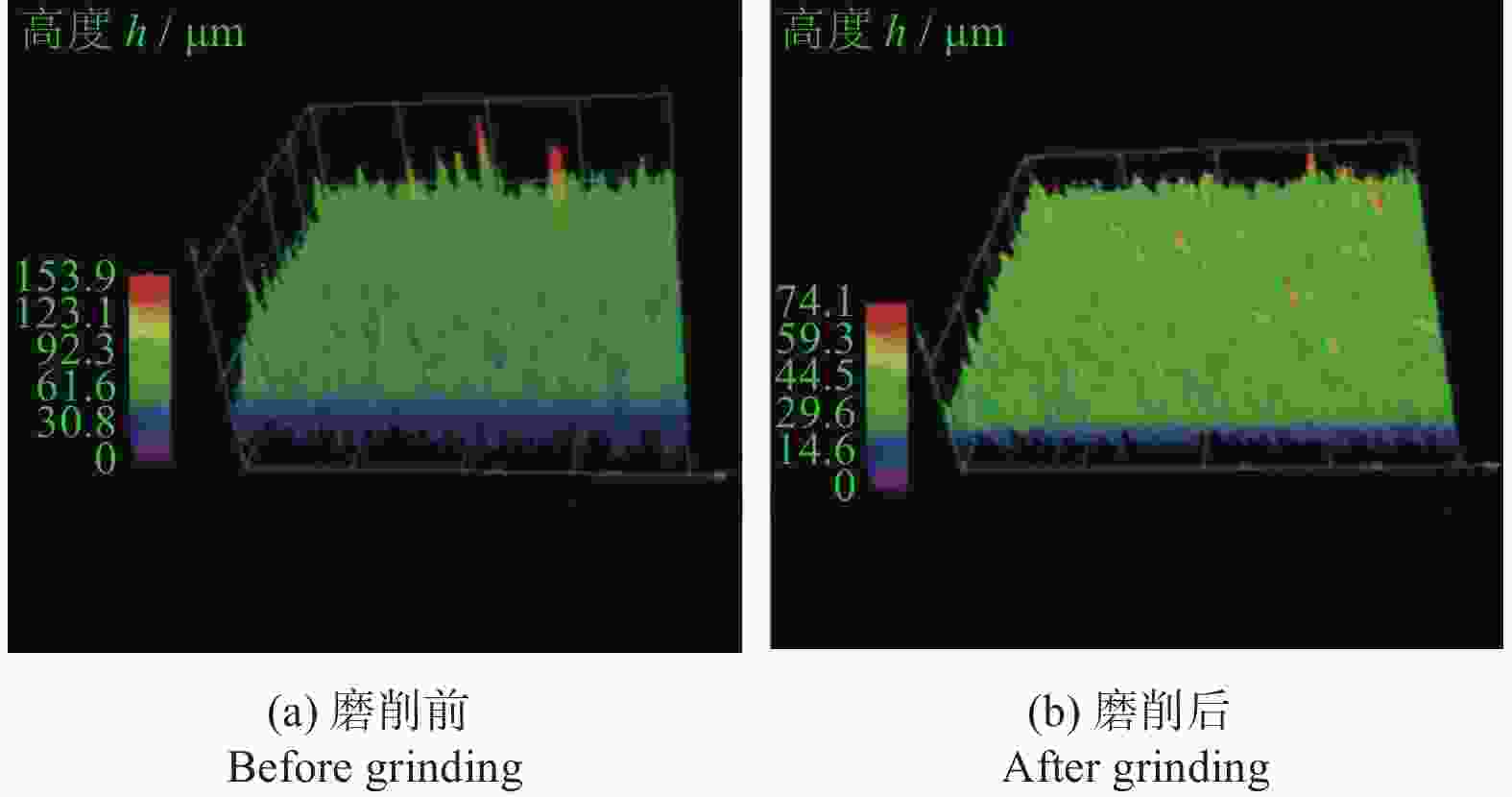

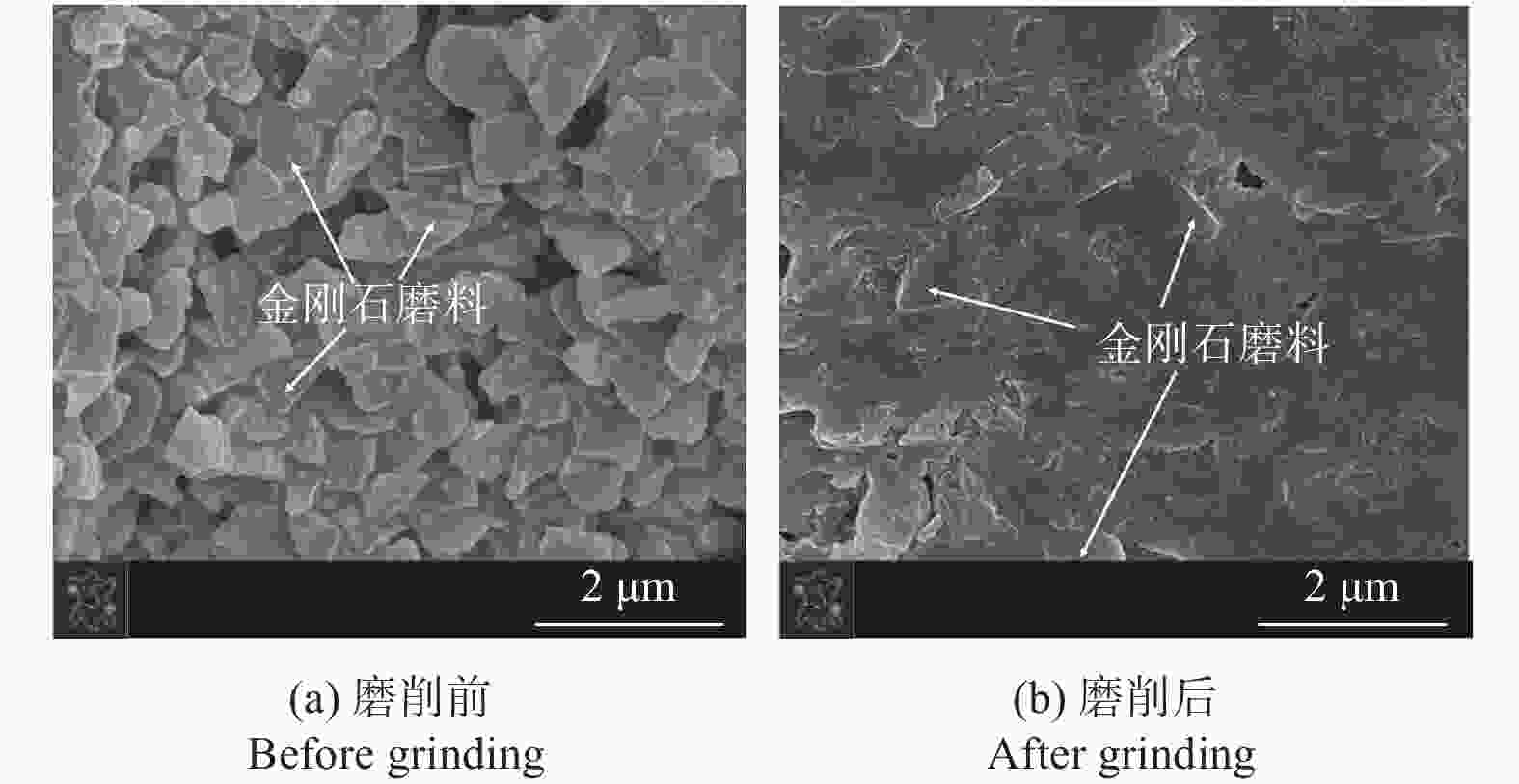

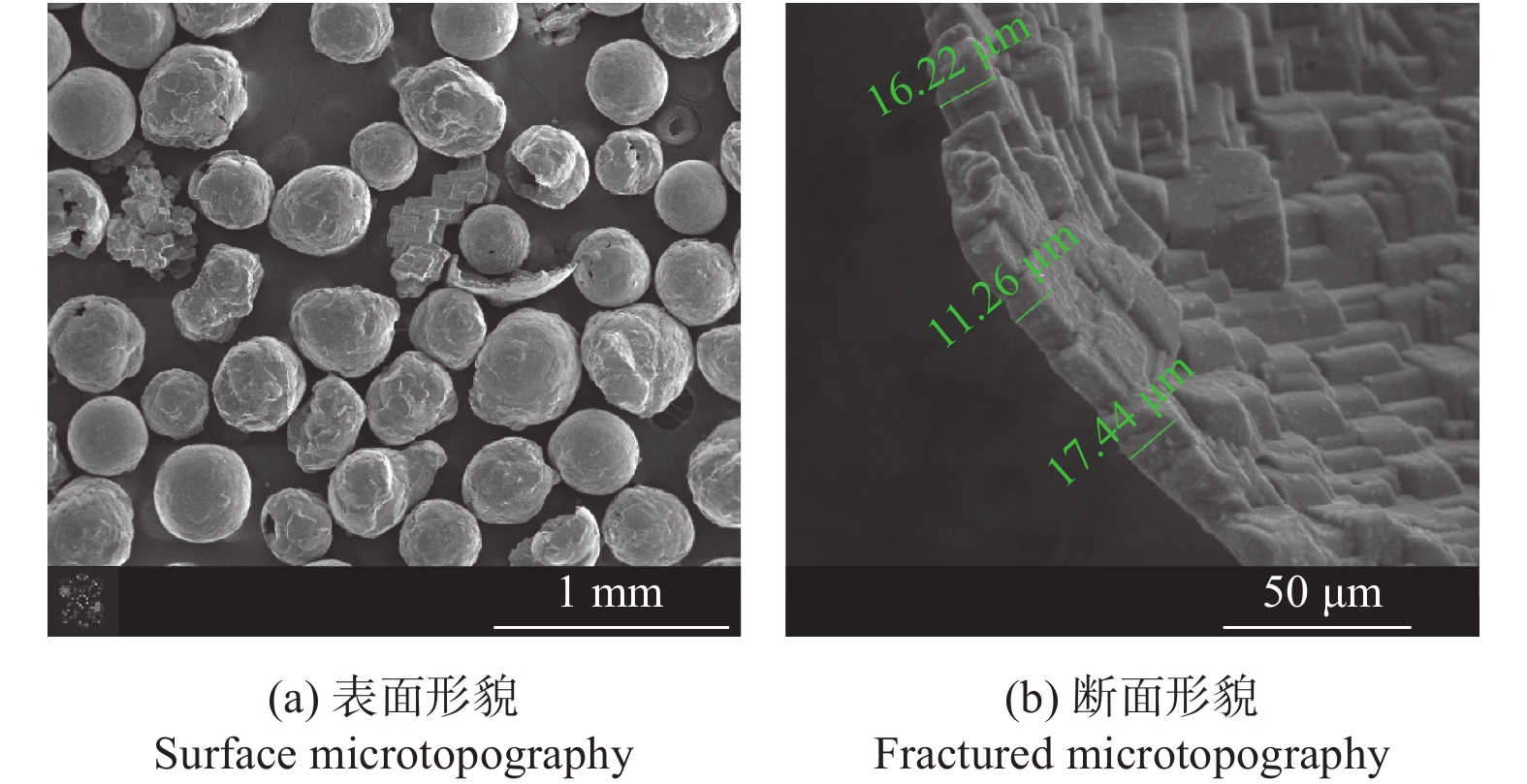

摘要: 研究空心氧化铝微球质量分数和粒径(0.2, 0.4, 0.6 mm)对砂轮的总气孔率、抗弯强度、硬度和微观结构的影响,制备以空心氧化铝微球为造孔剂的陶瓷结合剂金刚石砂轮,并研究砂轮对石英玻璃的磨削性能。结果表明:随着空心氧化铝微球质量分数增加,砂轮总气孔率升高,抗弯强度和硬度降低;空心氧化铝微球质量分数相同时,其粒径越小,砂轮的总气孔率越高,抗弯强度和硬度越低;制备的空心氧化铝微球陶瓷结合剂金刚石砂轮可用于磨削石英玻璃,加工后石英玻璃的表面粗糙度从0.5113 μm降至0.0206 μm。Abstract: The effect of the content and the size (0.2, 0.4, 0.6 mm) of the hollow corundum microspheres on the total porosity, the flexural strength, the hardness and the microstructure of vitrified bond was investigated. The ceramic bonded diamond grinding wheel with hollow alumina microspheres as pore forming agent was prepared, and the grinding performance of the grinding wheel on quartz glass was studied. The results show that with the increase of the content of hollow corundum microspheres, the porosity increases, and the flexural strength and the hardness decreases at the same time. With the same content of hollow corundum microspheres, addition the smaller size of microspheres could lead to the increase of the porosity and the decrease of flexural and hardness. The vitrified bond diamond wheel contained with hollow corundum microspheres can used to grind quartz glass, and the surface roughness can be reduced from 0.5113 μm to 0.0206 μm. Diamond wheel contained with hollow corundum microspheres can used to grind quartz glass, and the surface roughness can be reduced from 0.5113 μm to 0.0206 μm.

-

表 1 金刚石砂轮常用造孔剂及性能

Table 1. Common pore forming additives and their performance for diamond grinding wheels

表 2 不同质量分数的空心氧化铝微球砂轮配方

Table 2. Formula and the preparation parameters of grinding wheel specimens with different mass fraction of hollow Al2O3 microsphere

金刚石

质量分数

ωd / %结合剂

质量分数

ωc / %空心氧化铝

微球质量分数

ωa / %烧结

温度

θ / ℃保温

时间

t / h成形

密度

ρ / (g·cm−3)64.99 32.01 3.00 670 1.0 2.0 62.98 31.02 6.00 670 1.0 2.0 60.97 30.03 9.00 670 1.0 2.0 58.96 29.04 12.00 670 1.0 2.0 -

[1] 张贵锋. 超硬材料的研究进展 [J]. 材料导报,1996,35(3):35-38.ZHANG Guifeng. A survey of research on superhard materials [J]. Materials Reports,1996,35(3):35-38. [2] 谢德龙, 温简杰, 方啸虎, 等. 超硬材料制品产业近期发展现状与展望 [J]. 超硬材料工程,2014,26(1):39-42. doi: 10.3969/j.issn.1673-1433.2014.01.012XIE Delong, WEN Jianjie, FANG Xiaohu, et al. Current situation and expectation of the superhard material products [J]. Superhard Material Engineering,2014,26(1):39-42. doi: 10.3969/j.issn.1673-1433.2014.01.012 [3] 华勇, 李亚萍. 磨料磨具导论 [M]. 北京: 中国标准出版社, 2004: 47-153.HUA Yong, LI Yaping. Introduction to abrasive tools [M]. Beijing: Standards Press of China, 2004: 47-153. [4] JACKSON M J, DAVIS C J, HITCHINER M P, et al. High-speed grinding with CBN grinding wheels applications and future technology [J]. Journal of Materials Processing Technology,2001,110:78-88. doi: 10.1016/S0924-0136(00)00869-4 [5] LIU X P, QIAO A, WAN L, et al. Effect of ZrO2 content on the properties of diamond grinding wheel vitrified bond [J]. Journal of Wuhan University of Technology (Materials Science Edition),2014,29(1):19-22. doi: 10.1007/s11595-014-0860-4 [6] LIN K H, PENG S F, LIN S T. Sintering parameters and wear performances of vitrified bond diamond grinding wheels [J]. International Journal of Refractory Metals and Hard Materials,2005,25(1):25-31. [7] 左宏森, 关春龙. 造孔剂对金属结合剂金刚石磨具力学性能的影响 [J]. 金刚石与磨料磨具工程,2009,29(5):82-85. doi: 10.3969/j.issn.1006-852X.2009.05.018ZUO Hongsen, GUAN Chunlong. Effect of pore forming agents on mechanical properties of metal bonded diamond wheels [J]. Diamond & Abrasives Engineering,2009,29(5):82-85. doi: 10.3969/j.issn.1006-852X.2009.05.018 [8] LYU X F, LI Z H, ZHU Y M, et al. Effect of PMMA pore former on microstructure and mechanical properties of vitrified bond CBN grinding wheels [J]. Ceramics International,2013,39(2):1893-1899. doi: 10.1016/j.ceramint.2012.08.038 [9] DAVIS D T, SHELDON D, ERKEY C. Highly porous vitrified bonded abrasives by the selective extraction of butyl carbamate from green grinding wheels with supercritical CO2 [J]. Journal of the American Ceramic Society,2005,88(7):1729-1733. doi: 10.1111/j.1551-2916.2005.00276.x [10] 吕冰海, 董晨晨, 邓乾发, 等. 可溶填充剂对孔隙自生成超硬磨料磨具孔隙生成的影响 [J]. 机械工程学报,2014,50(15):172-179. doi: 10.3901/JME.2014.15.172LYU Binghai, DONG Chenchen, DENG Qianfa, et al. Influence of soluble filler on pores self-generation superabrasive tool [J]. Journal of Mechanical Engineering,2014,50(15):172-179. doi: 10.3901/JME.2014.15.172 [11] LIN Y H, FANG J B, XUE Q H. Effect of fly ash cenosphere pore formers on the microstructure and mechanical properties of vitrified diamond grinding wheels [J]. International Journal of Refractory Metals and Hard Materials,2017,67:82-89. doi: 10.1016/j.ijrmhm.2017.05.008 [12] MAO J B, ZHANG F L, LIAO G C, et al. Effect of granulated sugar as pore former on the microstructure and mechanical properties of the vitrified bond cubic boron nitride grinding wheels [J]. Materials & Design,2014,60:328-333. [13] 张习敏, 王明智, 王艳辉. 不同造孔剂对陶瓷结合剂性能的影响 [J]. 金刚石与磨料磨具工程,2002,22(5):19-22. doi: 10.3969/j.issn.1006-852X.2002.05.005ZHANG Ximin, WANG Mingzhi, WANG Yanhui. Influence of pore-forming materials upon the performances of vitrified bond [J]. Diamond & Abrasives Engineering,2002,22(5):19-22. doi: 10.3969/j.issn.1006-852X.2002.05.005 [14] 刘小磐. 陶瓷结合剂金刚石砂轮的制备及磨削性能研究 [D]. 长沙: 湖南大学, 2012.LIU Xiaopan. Study on preparation and grinding properties of vitrified bond diamond wheel [D]. Changsha: Hunan University, 2012. [15] 王超超, 张凤林, 李伟雄, 等. 空心玻璃微珠对陶瓷结合剂金刚石砂轮微观结构和力学性能的影响 [J]. 工具技术,2017,51(10):36-39. doi: 10.3969/j.issn.1000-7008.2017.10.009WANG Chaochao, ZHANG Fenglin, LI Weixiong, et al. Effect of glass bubble as pore former on micro-structure and mechanical properties of vitrified bond diamond grinding wheels [J]. Tool Engineering,2017,51(10):36-39. doi: 10.3969/j.issn.1000-7008.2017.10.009 [16] WANG C C, ZHANG F L, PAN J S, et al. An experimental study on preparation of vitrified bond diamond grinding wheel with hollow spherical corundum granules as pore former [J]. The International Journal of Advanced Manufacturing Technology,2017,93(1/2/3/4):595-603. doi: 10.1007/s00170-017-0475-y [17] BARBARA S B, JAROSLAW P, KRZYSZTOF N. Effect of porous glass-ceramic materials addition on the cubic boron nitride (CBN) tools properties [J]. Optica Applicata,2005,35(4):809-817. [18] 陈卫东, 涂俊群. 不同的造孔剂对陶瓷结合剂CBN砂轮性能的影响 [J]. 超硬材料工程,2014,26(3):1-5. doi: 10.3969/j.issn.1673-1433.2014.03.001CHEN Weidong, TU Junqun. Influence of different type of pore former on the mechanical property of vitrified bond cBN grinding wheel [J]. Superhard Material Engineering,2014,26(3):1-5. doi: 10.3969/j.issn.1673-1433.2014.03.001 -

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS